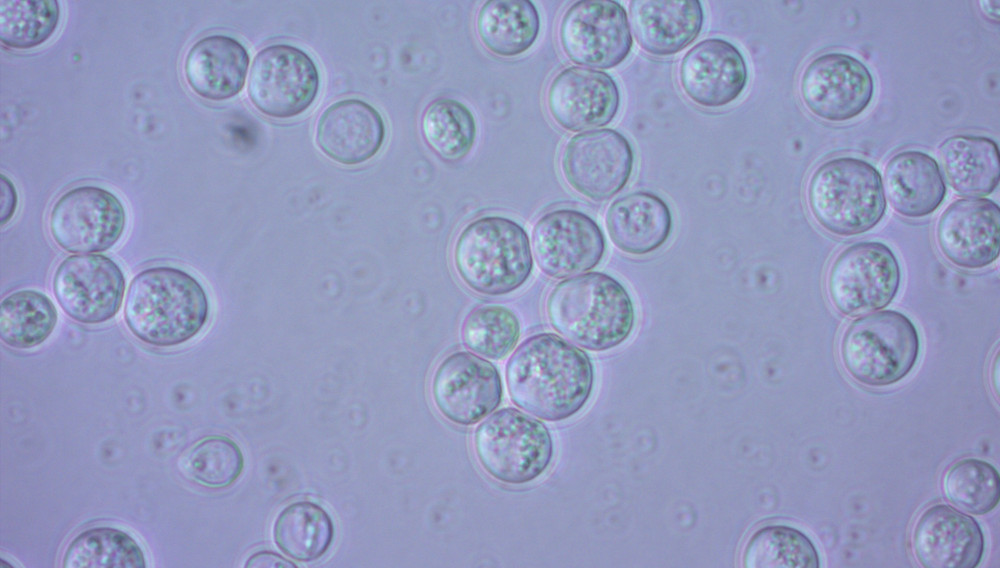

Yeast biodiversity | During the Corona crisis, some brewers used free capacities for product development. Novel maltose-negative yeasts from the “Hefejagd” (Yeast Hunt) project of the Research Center Weihenstephan formed the basis for more yeast biodiversity. This contribution looks at the tried and tested production of a non-alcoholic beer using Saccharomycodes ludwigii and analyses the yeast strains Cyberlindnera misumaiensis, Cyberlindnera saturnus as well as Kluyveromyces marxianus and their properties.

Developers want feedback | On October 1, 2020, Dr. Mark Schneeberger assumed leadership of Application Development Beverage & Beer at GEA in Kitzingen, Germany. He succeeded Dr. Rudolf Michel, who went into well-deserved retirement at the end of March 2021. BRAUWELT interviewed Dr. Schneeberger about his new position, one year on.

Eye-catching fermentation vats | It’s not only true of top-fermented beer styles that fermentation in a low, open tank enhances their taste and aroma. Tanks of the latest generation are made of stainless steel and fully automatically CIP-able – and can thus be used in 21st-century breweries without any reservations whatsoever. They have the ability to lend beer an emotional appeal that fascinates consumers.

Still on the up | As brands look to appeal to a growing group of ‘sober curious’ consumers, hard seltzers – alcoholic beverages containing carbonated water, alcohol and often with a fruit flavoring – are well placed to meet these demands. Hard seltzers present exciting opportunities for brands to differentiate their portfolios, but how can brewers overcome the new formulation challenges brought by hard seltzers while ensuring great-tasting beverages every time?

Promising alternative | Non-alcoholic and low-alcohol beers with a significantly reduced alcohol content are currently en vogue and meet the increasing health-conscious mindset of consumers, without having to forego the pleasure of drinking. Against this backdrop, many brewers are confronted with the question: is it possible to produce non-alcoholic or low-alcohol beers using existing equipment?

Yeast research in focus | The 4th BrewingScience Yeast Special will be published on April 29, 2022. The call for papers is open now.

The alcohol-free beer trend | After almost 30 years the Bavarian State Brewery Weihenstephan has invested in a new de-valcoholisation plant. This sets the oldest brewery in the world up for the future and enables it to perfectly cater for the growing demand for alcohol-free speciality beers. Greater productivity, flexibility and the use of cutting-edge technology were what triggered the decision to place the order.

Aging behavior | During experimental trials conducted to assess the reproducibility of the 2 hl pilot brewery at Hopfenveredlung St. Johann GmbH, it was determined that a number of hop aroma compounds were transferred from hops to beer. Subsequently, the behavior of these compounds in the finished beer over the course of aging was investigated [1].

Transfer of aroma substances | In search of a characteristic hop aroma in dry hopped beers, the potential of the hop variety Eureka! was investigated in more detail in brewing tests. This investigation focused on time-dependent transfer of selected hop components.

Immobilisation of yeast | Based on a new reactor concept, a continuous and immobilised fermentation process is being developed that meets the needs of modern breweries and maintains the advantages of continuous primary fermentation. State-of-the art crossflow filtration technology is used.

Overview | This article is an abridged version of the scientific paper “Fermentation and Spoilage Yeasts and their Relevance for the Beverage Industry – A Review” which appeared in BrewingScience in 2012 [13]. At the time, the article provided a summary of the latest findings on the subject of harmful spoilage yeasts and wild yeasts and still serves as a reference in the event that problems are encountered with these microorganisms.