Well-Equipped | Paradise Beverages (Fiji) Ltd, based in Suva, Fiji, was originally part of Pacific Ltd, a subsidiary of Foster’s Group. The company changed its name in 2012, when it became a member of Coca-Cola Amatil (Fiji) Ltd. Currently, the brewery, founded in 1957, produces about 100 000 hl annually. Paradise Beverages’ flagship beer is Fiji Gold, a pale lager with 4.6 percent ABV and comprises about 60 percent of the brewery’s production. In addition to the gradual renovation of the production facilities for packaged beers, the establishment of a high-gravity production facility is the brewery’s latest project.

Benefits of Omnium | The Omnium by Ziemann® brewhouse concept that will be unveiled at drinktec 2017 is covered in the final part of a series of articles “A Novel Mash Filtration Process” published in BRAUWELT International and is the result of interdisciplinary research. Omnium is the integration of the novel Nessie by Ziemann® process for mash filtration, opening up new possibilities in brewhouse operation resulting from different approaches and wort composition.

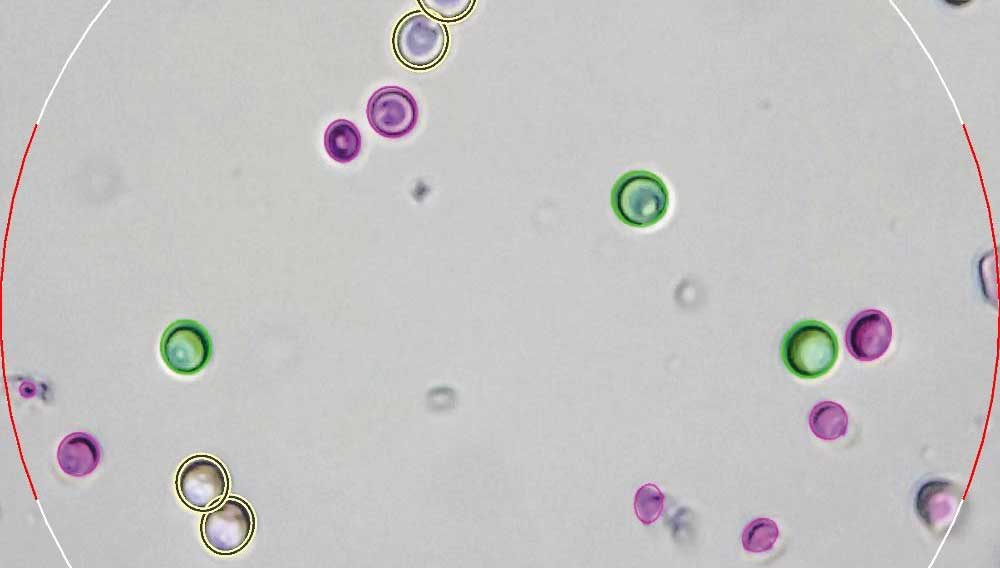

Taming the Wild Yeast | How do the strains of yeast we use for brewing and baking differ from their wild cousins? And when did the changes that make them more amenable to food production occur? Chris White and his colleagues have devoted their professional lives to working with and studying the microbes we employ in industrial food production processes, especially Saccharomyces cerevisiae.

The Finnish company developed new cold-tolerant hybrid strains that enable fermentation at lower and higher temperatures than before. In 2015 the company generated the first new lager brewing yeast strains in 500 years, and has now applied the knowledge obtained to create new yeast strains for the production of wine and cider. A key characteristic of these strains is that they can tolerate a wide range of temperatures from 10 to 37 °C. Importantly, the low temperature range reduces the risk of contamination during fermentation, possibly allowing for reduced sulphate use.

As breweries grow and build their brands, many seek to expand their outlets and exploit new markets with an export strategy. However, taking beer from one market to another often presents breweries – large and small – with a number of marketing and supply chain challenges. Nevertheless, by following some simple guidelines, breweries can avoid common pitfalls and make exporting a success.

In the article cited, wort preparation can be calculated in terms of evaporation and re-formation; this property is used here for predicting possible improvements. The second part of this five-part series of articles on improving wort preparation revisits a problem discussed previously: what is the best process for driving off DMS from wort?

Wort preparation is at the heart of beer production as the wort to be fermented is prepared from the natural raw materials water, malt and hops. The various steps are based on different unit operations. This five-part series of publications aims at improving evaporation of undesirable aroma substances. Part 1 covers practical implementation of DMS calculation published in BRAUWELT International No. 4, 2014, pp. 217-219, No. 5, 2014, pp. 284-288, No. 6, 2014, pp. 354-357.

Among craft brewers one occasionally hears the question: “Who aged beer in wooden barrels first?” Since barrels have been employed for storing liquid foods for millennia and beer brewing itself is many centuries older than the proper art of cooperage, asking such a question would seem puerile. The question appears impossible to answer – that is, until one begins inserting caveats. Though beer has been stored in barrels for a long time, by and large, brewers over many centuries have attempted to avoid allowing the wood to impart its own flavor to the beer – and they especially wanted to prevent any of the flavors and aromas derived from the beverage or food previously stored in the barrel to corrupt its contents. As with so much else, however, there has been a sea change in the use of barrels amongst craft brewers. We will conclude our discussion in the final installment of this series by taking a closer look at how brewers have awoken to the potential barrels can offer in the creation of unique and characterful beers.

Until around 20 years ago, secondary fermentation in the bottle was widespread among most breweries producing Southern German-style wheat beer. However, since then, the majority of them have abandoned traditional bottle conditioning in favor of secondary fermentation in tanks. There are multiple reasons behind the move away from bottle conditioning aside from the need to simplify and standardize the production process. It was primarily the desire to avoid yeast autolysis and to achieve uniform and stable levels of turbidity which were the motivation for seeking alternatives to bottle conditioning.

Key performance metrics for efficiency are established tools for quantifying bottling line performance. They provide a comparison of ideal volume and actual production volume. Expressed as a ratio, this figure can be used to quantify production losses. However, as is frequently the case, the devil is in the details; therefore, selecting the correct metric is essential.

Entering the fantastical realm of microbes by becoming engrossed in their goings-on under the lens of a microscope can be compared to Alice stepping through the looking glass. Tumbling down the zymurgical rabbit hole into the distance past, we see amphorae become the first and most common containers for liquid foods. They were in use for centuries, and owing to their porosity, they were able to harbor microbial communities. These microbes ultimately affected the character of many of the liquids stored in them, including beer, the ambrosia of the Levant, Mesopotamia and Egypt during the Bronze Age. Barrels have since taken over the role of housing the microbes – both foul and fair – that inoculate their contents.