Compact system | Retrofitting a modern empty bottle inspector is also possible for small and medium-sized companies with limited space. For lower outputs of up to 36,000 bottles per hour, Heuft has developed a space-saving inspector that fits into just one square meter, as is the case at the Raab private brewery in Hofheim, Lower Franconia, Germany.

Predictive failure prevention | Do you want to hedge your bets and hit the jackpot? Then maybe you should consider making use of a tool from the extensive quality management toolbox: FMEA. Failure mode and effects analysis is now slightly out of fashion and, as far as we know, barely used in the beverage industry – if indeed at all. If you study it in greater depth, however, you soon realise its potential.

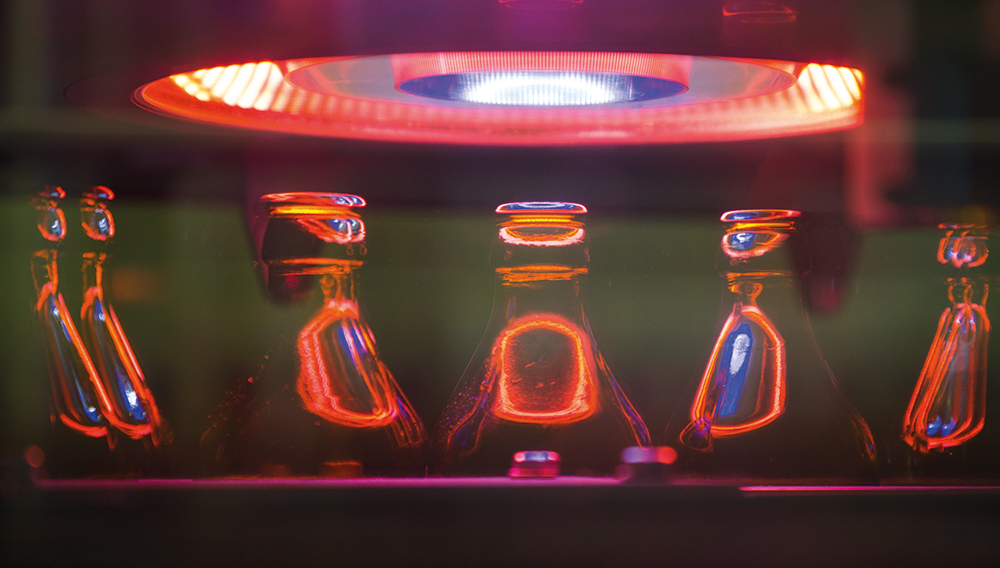

Quality control | AI, or artificial intelligence – this buzzword is currently being discussed in many contexts. Opinions range from outright rejection to the expectation that AI will do everything better. In fact, it has been observed in many discussions that this complex topic is often only considered in general terms, and the specific details are frequently ignored. Therefore, we will try to take a closer look at the topic for applications of automatic quality control during beverage filling, in particular for empty bottle inspection.

Resource efficiency | Aside from a few select beer styles (such as Kellerbier or most wheat beers), clarity and brilliance are essential quality parameters for clear-filtered beer. Moreover, consumers expect the beer to not change within its suggested shelf life. Beer clarification and stabilization are necessary to meet these requirements.

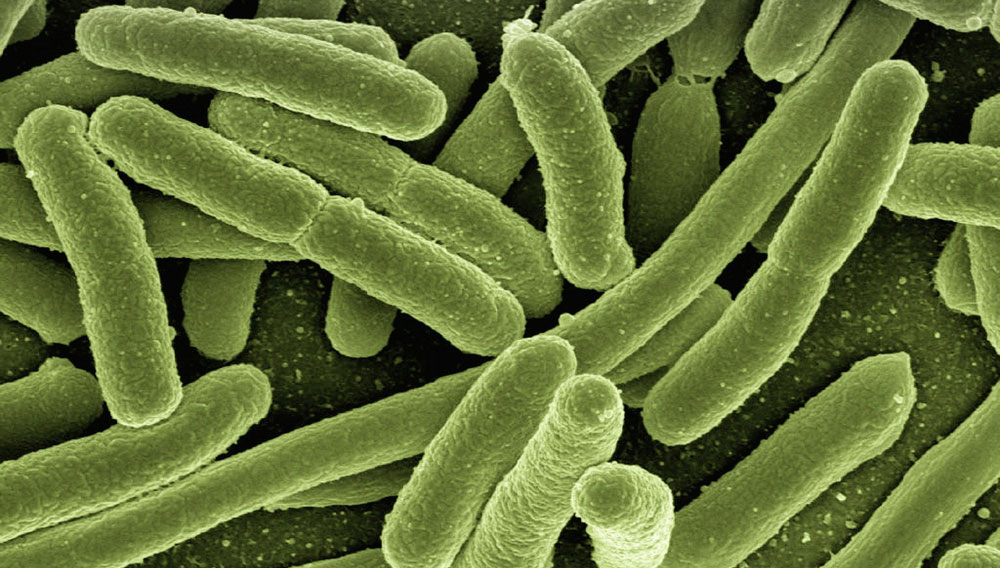

Contamination | Hygiene deficiencies on filling systems are usually a home-made problem. Even if this sounds like an extremely simple statement to make, nevertheless it’s a fact. But why is this so? And why do quality controllers today often not identify the weak points at their own plant? This requires some explanation, for it’s not for lack of suitable training.

Returnable glass line | The Paulaner Brewery Group has upsized its filling capacity in 2022 with a new returnable-glass line rated at 50 000 bottles per hour. This order, for the Munich-Langwied plant that was built eight years ago, marks Krones’ first filling technology order from Paulaner. The returnables line is as compact as they come and nevertheless offers an operator-friendly layout – on just 1400 square meters of floor space.

Cleaning results validated | Spray shadow tests are a useful and proven tool for validation of automatic cleaning systems. This holds true for new installations, changes to existing systems and regular revision. Based on two industrial examples, the usefulness of two different spray shadow tests, both used at VLB, is illustrated.

Sustainable filling | One of the vital issues for any forward-looking brewery is this: How can I save energy throughout the production process, in order to put it on a more sustainable footing? The Brewnomic concept from Steinecker, a Krones subsidiary in Freising, Germany, consists of several modules, many of which relate to the brewing process. But systems and lines used in the bottling operation can also contribute to overall sustainability. The Krones Dynafill system combines filler and capper in a single functional unit and contributes to the concept of a carbon neutral brewery.

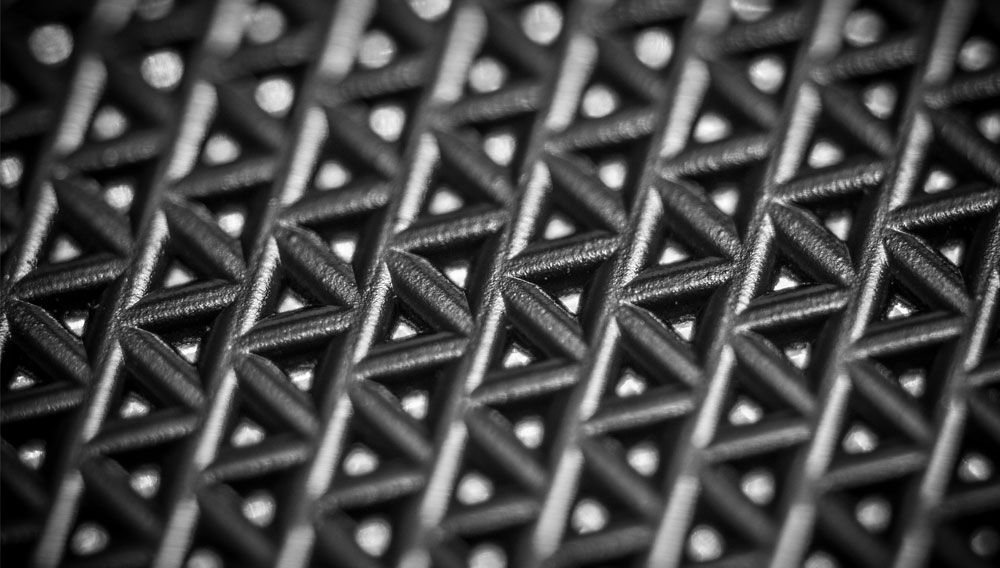

Data analysis | Increasing digitalisation makes it possible to collect and analyse copious amounts of data with multivariate cause-and-effect relationships. However, brewery operations face major challenges when attempting implementation on their own. This contribution presents findings and solution pattern from the research project “Data-driven Process Optimisation using Machine Learning in the Beverage Industry” (DaPro).

Brewery hygiene | If we look back on 50 years of brewing microbiology, we gain a number of extremely interesting insights. Can we draw a positive conclusion here or are there also negative aspects that have to be taken into account?

Successful installation | Using high-tech from KHS, AB-InBev subsidiary Cervejas de Moçambique in Mozambique has now built the biggest and most modern brewery in Africa. The heart of the system is what the customer claims to be the fastest returnable glass line on the continent, whose successful installation and commissioning neither a catastrophic tropical cyclone nor the raging corona pandemic were able to prevent.