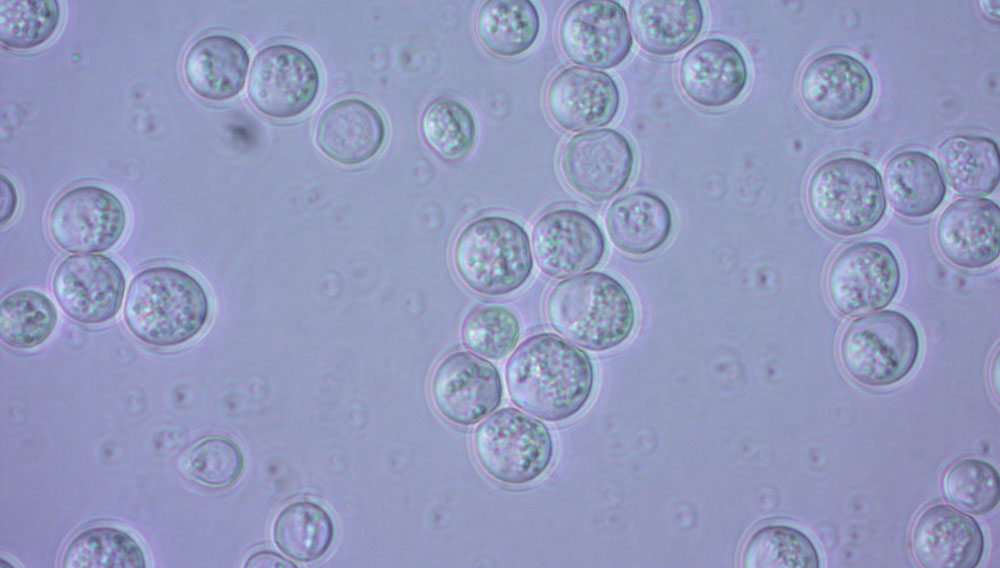

Presentation of methods | Vitality of yeast is a major issue for every brewer. This applies to both yeasts propagated from professional yeast management as well as to fresh rehydrated dry yeasts. Modern brewers can choose between several methods for determining vitality of their yeast cells. One of these methods is the Acidification Power Test which can be carried out quickly and cost-effectively.

Real-time monitoring | From Austria comes an interesting new technology that will permanently change the water treatment processes in the beverage industry and make them more efficient: the ColiMinder, an on-line instrument for fully automatic monitoring of microbiological water quality in the beverage industry.

Beer from the time of the Kaiser | The discovery of a very special bottle, a relic from the German Empire of 1871–1918, has aroused much interest. Scientists from the Technical University of Munich (TUM) have now analysed samples of this historical beer. Their extensive experiments reveal a number of details about the dawn of industrialisation in the brewing trade.

Trained senses | Is a sensory panel suitable as an “analysis instrument” for monitoring the quality of spirits? Can training a panel specifically for detecting wood-derived substances, key aroma substances, color and faults common in whiskey supplement, or even replace, laboratory analysis for measuring individual substances? Are there limits, and if so, what are they? This is the third installment in the series, which began with the basics of barrel aging in part 1 and continued with the laboratory analysis of barrel-aged spirits in part 2 [1, 2]. In this installment, the authors will consider another measuring device: human beings.

Simulated barrel maturation | How do the aromas and color of spirits develop during barrel maturation? What roles do the degree of toasting and the type of wood play? What is the most practical method for determining the phenolic compounds and the volatile substances in wood, such as higher alcohols, aldehydes, esters and lactones? With gas and liquid chromatography? The authors recreated the process of aging in wooden barrels in the laboratory and analyzed the processes of extraction, color and aroma formation.

Visual foam stability | The quality of beer foam depends on many factors, including initial foaming, head retention, lacing and so on. Most foam analysis methods focus mainly on head retention. Using such methods, foam membrane strength for head retention was shown to be an important aspect. Could this factor be responsible for head retention only? And what role do hop bitter acids play in this? The following article summarises some research results which have already been published in BrewingScience, 2021, issue 6: November/December.

Beer analyses test beers | During dry hopping, extraction of hop aroma poses multiple challenges for brewers, as has been described in Part 1 of this series of articles. In this second part of the series of articles, a method on a laboratory scale is presented in which extraction of hop aroma is carried out by re-dilution.

Popular drink | Hard seltzer, a low-calorie and low-carbohydrate alcoholic drink, is one of the trendiest current alternatives in the alcoholic beverage industry. To meet the expectations of consumers for consistent taste and the requirements for correct labelling and declaration of the alcohol content, an accurate, simple, and fast analytical solution is required. Anton Paar conducted a study to explore whether different analytical methods conform to an officially acknowledged reference method (e.g., distillation).

Foam stability | Various physical phenomena can be observed in beer foam. Foam membrane strength is an important factor influencing head retention. When comparing various foam analysis methods (Sigma, NIBEM and FCT developed by us), it was found that NIBEM and FCT were more sensitive in determining foam membrane strength than Sigma. In this article, the importance of the composition of hop bitter acids for foam membrane strength and visual foam stability is described. It summarises some research results which have already been published in BrewingScience, 2021, issue 6: November/December.

Measuring turbidity and color | Color has a significant impact on how a consumer perceives the quality of a glass of beer. Defined by type and brand, the consumer has a clear expectation of what a beer should look like. Turbidity has found its way back into beer. For decades only seen in specific beers like wheat beer or Belgium-styled beer, craft brewing has brought haze back into the glass. How do color and turbidity influence each other? What do you need to be aware of if measuring both of them at the same time? This article spotlights two different technologies used in breweries for inline measurement of color, small and large particles, and handle buildup or fouling on optical windows.