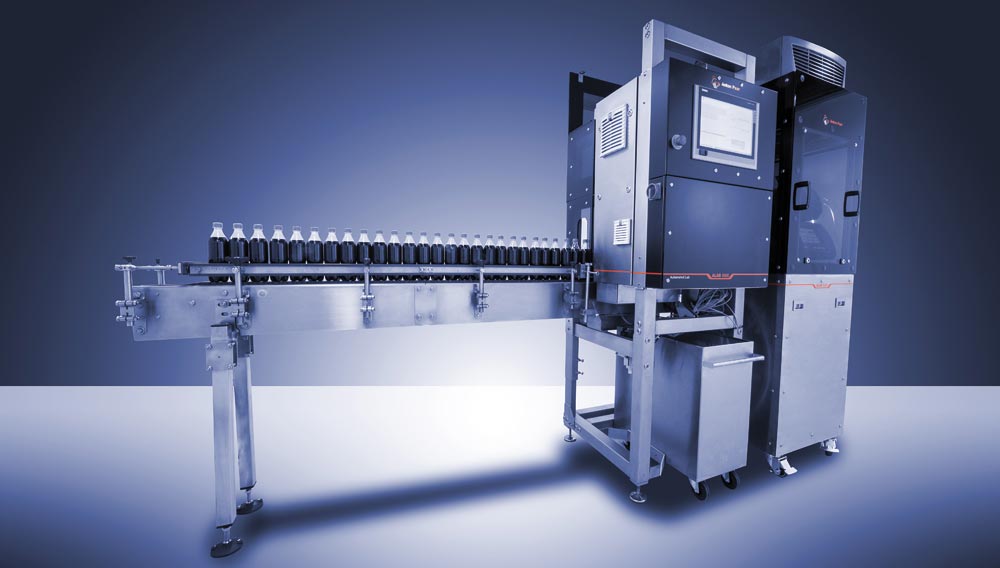

Inline and fully automated | Conventional quality control carried out in the laboratories of breweries and beverage producers is usually performed manually and requires a significant amount of time and labor. With the automation solutions available from Anton Paar, the laboratory is located directly on the production line.

Improved process control | Real-time measurement of process parameters is indispensable for achieving high process efficiency. Diacetyl, an indicator substance for assessment of fermentation processes and thus the point in time for cooling and hosing in the brewing process, is accorded particular commercial importance. This article provides an overview of existing measurement procedures and the potential for further development.

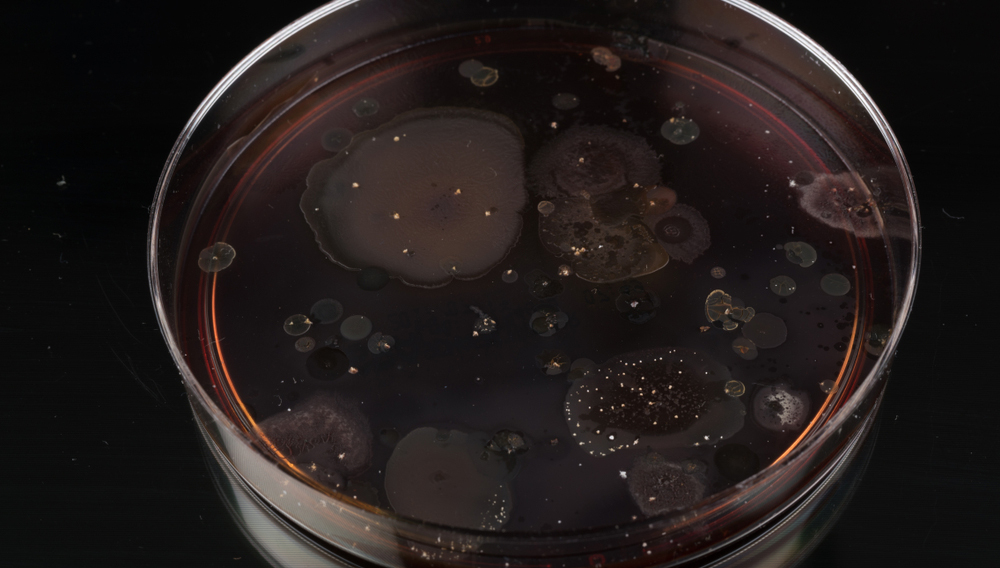

Optimising evidence | Detection of beer-spoilage bacteria in the brewing process is of the utmost importance. These bacteria can cause, among other things, hazes, acid and off-flavours in the product. It is extremely difficult, especially in pure culture yeast and also in cropped yeast, to track down these beer spoilers because their growth is suppressed by yeast. In addition, these bacteria are often present as trace contaminants in such yeast. In this study, a method has been developed to detect beer-spoilage bacteria in pure culture yeast much faster and with a higher degree of reliability than has been the case with existing methods.

Establishing a measurement methodology | The arabinoxylan substance group has been hitherto largely disregarded in the area of beverage analyses and interpretation of technological repercussions, this is due in part to the limited availability of measurement methodology. However, it is a cell wall component that should not be underestimated and is possibly – in addition to β-glucans – another important indicator or technical parameter for cytolysis.

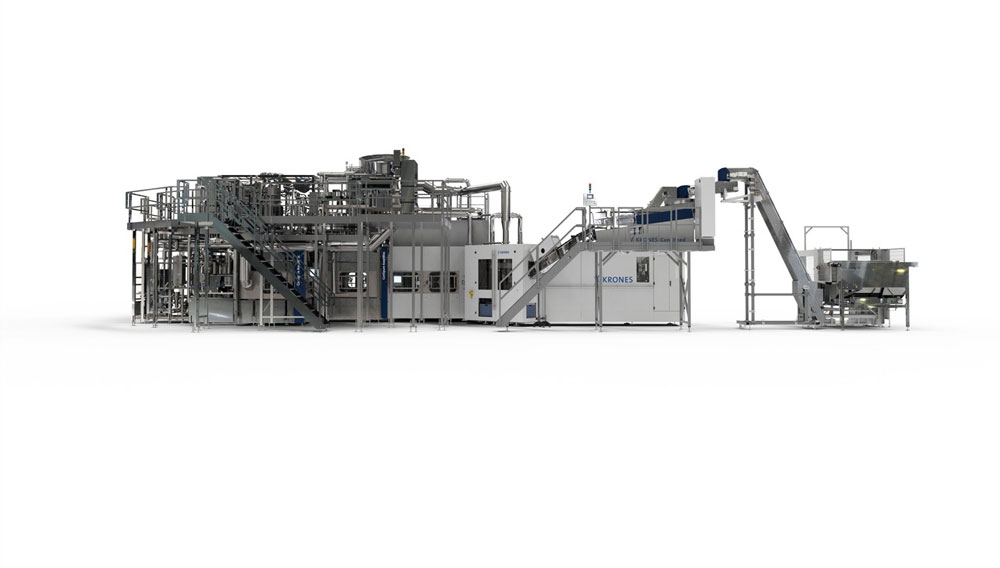

Krones | In the field of aseptic filling, Krones’ portfolio includes specialised machines for the various sterilisation techniques and products involved.

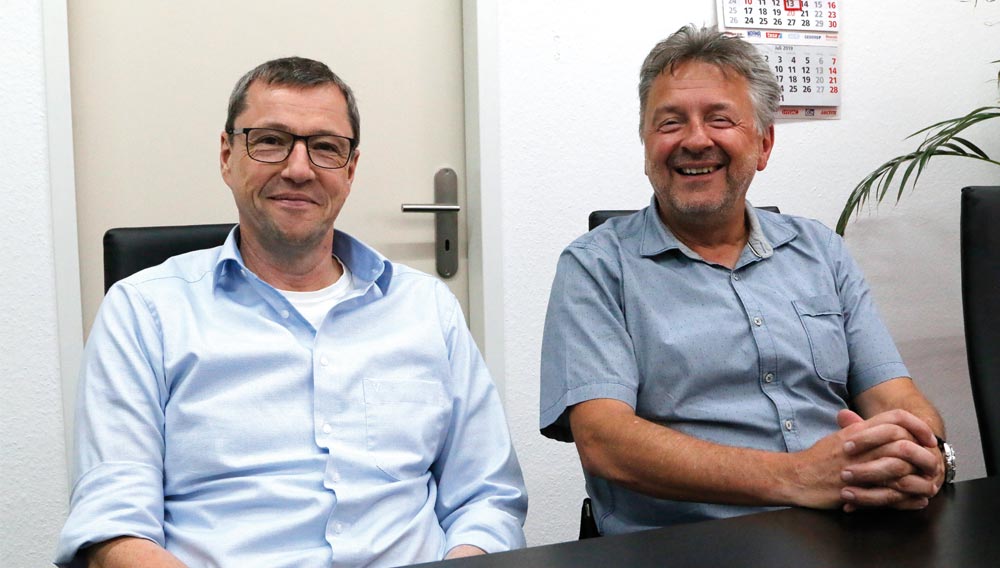

Professional exchange | Johann Angres, Managing Director of Steinfurth Messsysteme in Essen, Germany, received a great honor in April of 2019. He is the first German ever to be elected to the board of the ISBT. Never heard of the ISBT? The International Society of Beverage Technologists is the MEBAK or EBC of the soft drink industry. And because we also were not familiar with the ISBT, we decided to visit Johann Angres in Bochum to find out more about the association, his appointment to the board and the changes currently taking place at his company.

Flow cytometry | The risk of primary and secondary infection in beverages can be reduced if a beverage production facility is clean at all times and in all areas. Ensuring this is one of the central and cost-intensive tasks of beverage production. But how can you be sure that all pipes and equipment are always clean? How can this be monitored almost in real time?

Genetic test | Some contaminant yeasts make beer bottles and cans explode. Apart from being dangerous for consumers these ‘diastatic’ yeasts also cause loss of beer batches due to off-flavours, increased alcohol and over-carbonation in products. VTT scientists developed a genetic test for brewers to detect the strains that cause these problems.

Beer analyses | The Omnium brewhouse concept by Ziemann has been operating successfully for the first time in a German brewery, Schlossbrauerei Reckendorf, since the beginning of April 2018 [1]. In the first part of the technological considerations, the results of brewhouse operation based on process times and data from wort analyses were explained [2]. The repercussions for beer quality resulting from technological factors described will be examined in this second part of the article.

Copa-Data GmbH | Together with zenon 8.10, the Salzburg-based manufacturer is also releasing a new version of its zenon Analyzer 3.30 reporting and analytics software.