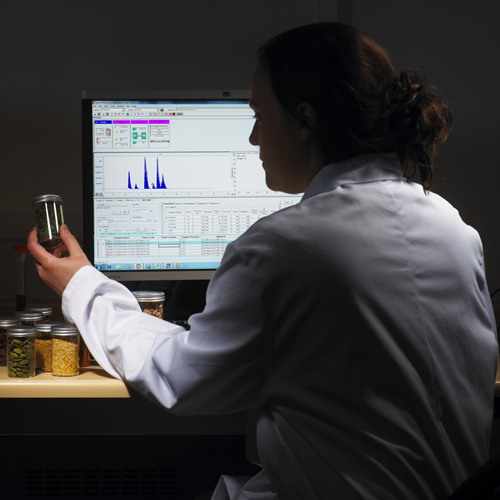

Specialist laboratories | Whether microfibres or glyphosate – the latest scandals in recent news have once again shown that food and beverage manufacturers need to be able to respond to unexpected queries concerning their products. Luckily, the most common concern is an easy one – whether or not the product contains a certain substance. Whatever the answer, proof is required. To answer these kinds of questions manufacturers need access to a specialist laboratory with the relevant analytical expertise, or one that can develop it as quickly as possible – sometimes within a matter of hours.

“Women are enchanted by charm and appearance – one more reason why craft beers are all the rage.” This insight into the current trend of craft beer was provided by the well-known German talk show host and book author Sonya Kraus. She should know. After all, she is active as an ambassador for beer, even if she perceives the success of traditionally brewed specialty beers from a very feminine perspective. But what’s wrong with that? The fact is that more and more German consumers are discovering their passion for originality and individuality in beers far removed from those mass produced on an industrial scale. Similarly, more brewers have become caught up in the growing enthusiasm seizing the industry and are giving free rein to their creativity.

Campden BRI has opened a brand new, purpose-built laboratory at its Chipping Campden site.

All over the world, manufacturers are under increasing pressure to manage natural resources in a responsible manner. This applies also to the brewing industry. Since most processes in a brewery are carried out batch-wise, energy and water recovery and reuse in a brewery is complicated though this is becoming more widespread now. In this first part of the publication, the brewhouse and cellar processes are mapped with the aim of calculating real brewery requirements for heating, cooling and fresh water usage in each step of the process. This flow sheet can then be optimised to lower overall water and energy consumption.

The International Committee for Hop Standards (ICHS) recently announced that from now on a new calibration standard ICS-T3 is available for HPLC analysis of tetrahydroiso-alpha acids.

Boon Rawd Brewery Co., Ltd., the first brewery of Thailand, was founded by Phya Bhirom Bhakdi in 1933. Since then, the privately owned company has constantly expanded and diversified. It awarded GEA Brewery Systems the contract for the expansion of the brewery in Banglen, 70 km northwest of Bangkok.

Microbiological stability of non-alcoholic, low-alcohol and mixed beer beverages is frequently inferior to that of comparable full beers. Protective factors inhibiting microbial growth in beer are fewer or “diluted” or not present at all. However, new protective factors may also come to the fore. As reliable data for objectively assessing microbiological risks associated with these beverages is, in most instances, not available, a system for assessing such risks has been developed.

Krüss GmbH presents a new module for the DFA100 Dynamic Foam Analyzer intended for the optical testing of fluid foam structures. The instrument uses image analysis to determine the number, size and size distribution of the bubbles of a foam generated under control in the instrument. The foam structure module features a height-adjustable camera with rapid image sequence for measuring the structural changes over time, thus making the inner destabilisation of the foam visible long before it actually decays.

What do the seafarer Christopher Columbus and former U.S. Defense Secretary Donald Rumsfeld have in common? Well, put simply, they believed that the New World got it better than Old Europe. For centuries, Europe’s intellectuals have envied America for being free from the ancient traditions that are Europe’s heritage and curse. The same could be said for Europe’s microbrewers. Striving for greater visibility and acceptance in Europe’s highly competitive and declining beer markets, where do they look for inspiration and support? To the United States. Obviously, nothing changes?

Utilizing real-time Polymerase Chain Reaction (PCR) technology, Pall’s GeneDisc test provides a fast, reliable and user-friendly detection method to identify typical beer-spoilage bacteria.