Rapid microbiological tests | Beverage dispensing systems are designed to serve beer and non-alcoholic beverages as well as wine and e.g. fruit juices to patrons in the hospitality sector. They are subject to food safety regulations due to their role in beverage treatment. Consequently, European and national food-related regulations have to be complied with and thus specific cleaning processes and, if required, checks have to be in place.

More is possible | In part one of this publication, the definition of what actually constitutes a clean bottle was examined in greater detail as a condition of all efforts to save on fresh water. Technical developments and our own individual efforts have considerably reduced the amount of fresh water and energy consumed by bottle washing over the past few years, with these endeavours now apparently having reached their limits. In order to pinpoint further potential for relevant savings, a new approach was necessary, the practical significance and implementation of which shall now be presented in part two of this series.

Clean bottles | Continuous further development and step-by-step technological optimisation have steadily reduced the amount of fresh water and energy used in bottle washing systems. This endeavour is restricted by various physical conditions and plant operators’ top priority of producing a clean bottle, however, with these limits now apparently reached. Here, the patent-pending TC-Ecojet solution from Tensid-Chemie tackles this problem from a completely new angle by employing a number of effective measures.

Water quality | Dipole H2O is much more than ‘just’ water – even if we don’t always think of it as such in day-to-day operation. For the brewer, water can be an ingredient (with very specific requirements), a finished product, a cleaning agent, an operating material, a source of energy, a coolant, a waste material, a lubricant, a solvent, a neutralisation medium, a test medium, a rinsing solution – and a whole lot more. In this article, Lars Peuker describes various experiences with microbiological hazards and defence strategies in relation to water.

Decomposition product | After introducing a limit value for chlorate in the German Drinkaing Water Regulation, there is growing concern as to whether chlorine dioxide can still be a suitable disinfectant. Pursuant to EU 2020/749 (Maximum Residue Levels for Chlorate in or on certain Products), different limit values exist. Pursuant to the German Drinking Water Regulation 2023, a limit value of 0.07 mg/l of chlorate applies.

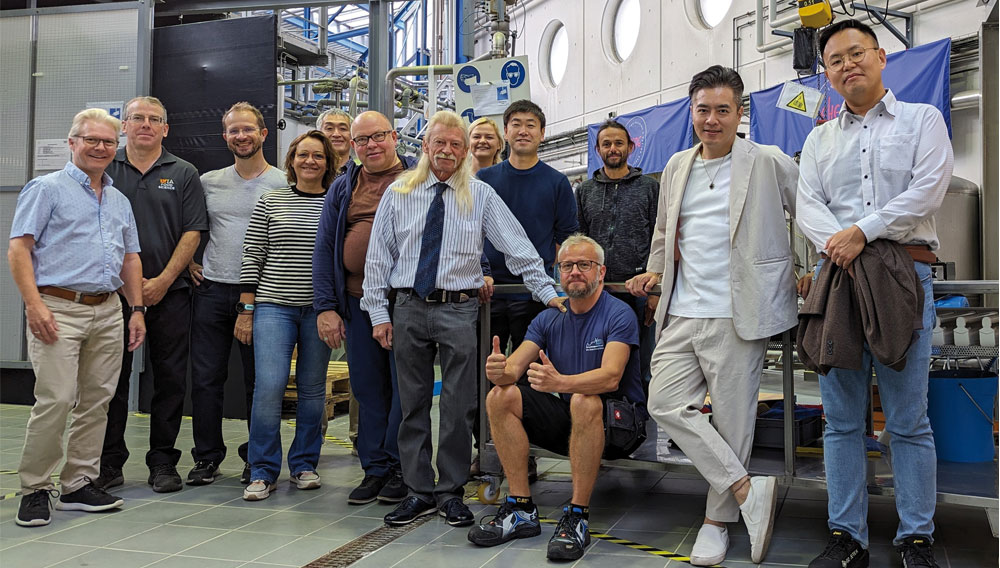

Proof of quality | The fifth and final part of the BRAUWELT series on hygienic design describes the possibilities for getting EHEDG certifications. Operators thus have independent proof that components and fittings comply with the requirements of hygienic design and are thus optimally suited for installation in beverage production. An independent assessment by customers is not trivial as the term “hygienic design” is not protected. The Research Centre Weihenstephan for Brewing and Food Quality of the Technical University of Munich (BLQ) is one of the testing laboratories authorised by EHEDG to carry out such certification.

Saving water | In the brewing industry, too, the focus has turned to the consumption of our precious water resources in an attempt to minimise our impact on the environment. Water isn’t just the main ingredient in the production of beer but also essential as process water, such as in the use of the pasteuriser, reverse osmosis, the cooling tower and wastewater system. Efficient measures and technologies can help to significantly reduce the amount of water consumed in these areas and thus enable breweries to operate more sustainably. In this article, various approaches will be outlined as to how breweries can increase their water efficiency using specific measures.

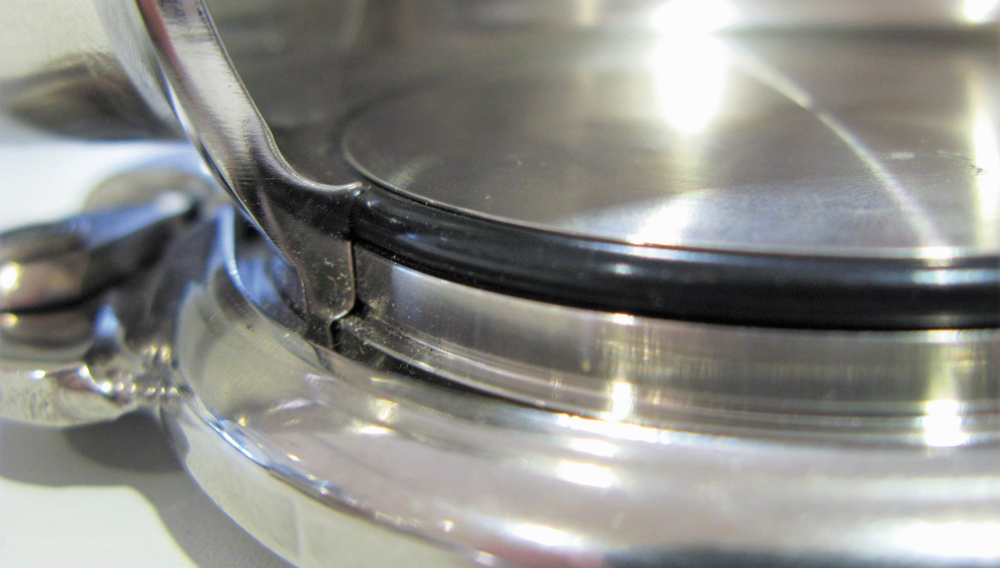

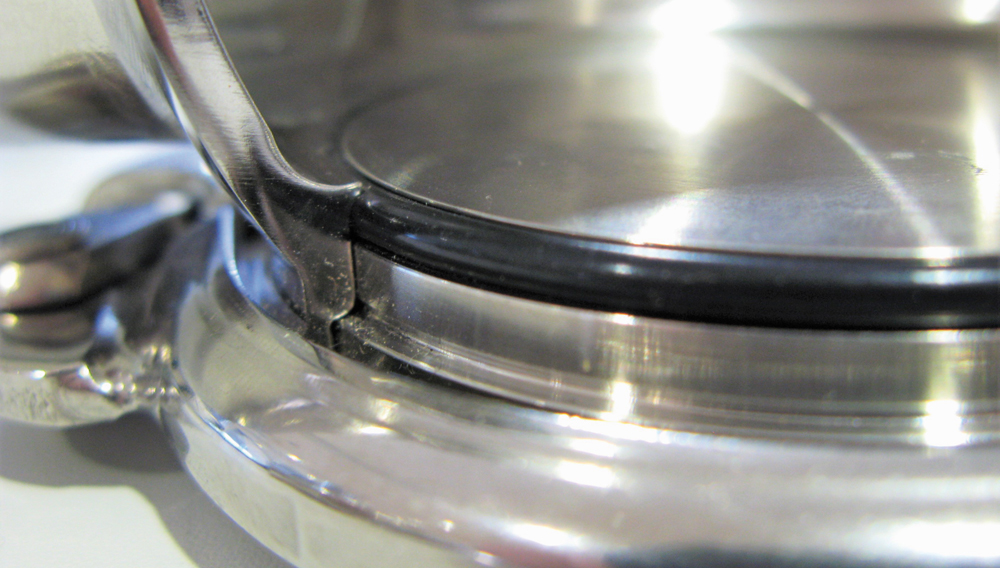

Best prerequisites | The fourth part of our Hygienic Design series introduces the European Hygienic Engineering and Design Group (EHEDG). The German test centre is located at the Weihenstephan Research Centre for Brewing and Food Quality (BLQ). Its particular facilities ensure that Hygienic Design assessment, so important for the brewing and food industries, can be carried out.

Aseptic filling | The third part of the BRAUWELT series about hygienic design covers a very specific application: aseptic filling. For these processes, it is important that fittings have special properties. To test whether fittings are suitable for aseptic processes, the Weihenstephan Research Centre for Brewing and Food Quality at the TU Munich offers specific EHEDG testing methods. These are, among others, the basis for an EHEDG aseptic certification.

Disinfection processes | Chlorate is a by-product of disinfectants harmful to health. It can form during water disinfection and thus has to be monitored during beverage production. It is important to become familiar with the causes, legal framework, recommendations, sources of ingress and implications for health of chlorate in order to develop effective prevention routes and strategies for avoiding exposure to chlorate. In this technical article, the focus is on these measures from the aspect of “Safe and low-chlorate operation of disinfection plants existing or planned”.

Cleaning efficiency | Modern CIP systems are only a point of discussion when they don’t work as they should do. CIP systems provide great service for a long time without any grounds for complaint or the need for any further intervention – bar the necessary maintenance. Their degree of efficiency can decrease, however. More detailed study of CIP systems reveals that they do indeed have several weak points that can mutate into risks.