Product development | The second installment in this two-part series focuses on innovative products that can be created using techniques and equipment commonly utilized in breweries. In this segment, we will take a closer look at producing beers using special yeast strains as well as unfermented, non-alcoholic beverages.

Small mash filter with a high yield | Various manufacturers offer powerful mash filters. When original gravity and the proportion of raw fruit are high, membrane filters in particular have advantages in terms of efficiency and cycle time. Small-size filters are on the market that are well suited for craft and pilot breweries. The aim of a pilot study was to develop a filter that, though small, has a high extract yield comparable to that of large filter systems.

Isothermal high temperature mashing | In this paper, we present a report on the production of low-alcohol beers using the isothermal high temperature mashing process with single-variety Leandra barley malt. For the purpose of this study, isothermal mashing was conducted at four distinct temperatures (72°C, 74°C, 76°C, and 78°C). In addition to the alcohol content, the structure of the extract, the free amino nitrogen (FAN) content, and the sugar distribution, which allows conclusions to be drawn about enzyme activity, were also examined. There were negligible disparities in the build-up of the extract or the free amino nitrogen content. However, the release of fermentable sugars, primarily maltose, exhibited significant variation. The increase in mash temperature from 72°C to 78°C resulted in a substantial decrease in fermentable sugar content, consequently leading to a significant reduction in alcohol content.

Tart and lively | This two-part publication takes a closer look at innovative products that can be made using existing brewing techniques and equipment. In this first installment, the authors examine beverages produced using fermentation.

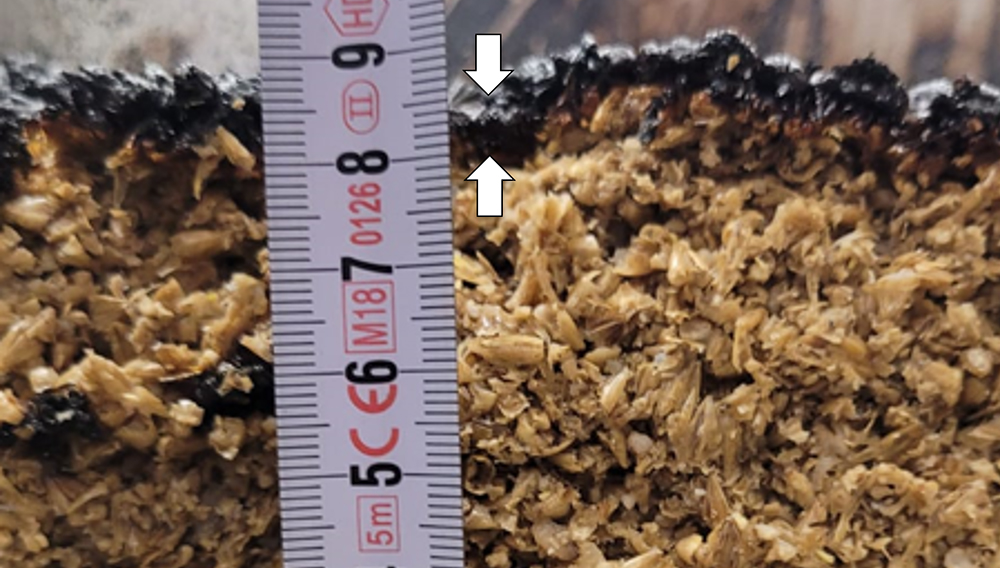

Let’s bake and brew | Keptinis is a traditional Lithuanian beer made of baked mash. The mash is roasted at temperatures of over 250 °C in a stone oven. Hardly any measurement data on the properties of this type of beer is available. The information that does exist is primarily based on what has been passed down orally and what can still be found in old housekeeping books.

Magpie&Marten | Dear readers: The following discussion continues one that began in our previous column in the print edition of BRAUWELT International, which is about the rising gelatinization temperature in barley.

Increasing efficiency | The economic situation is currently challenging for many breweries. Regardless of the reasons, it is essential for efficient and thus sustainable operations to use the raw materials as effectively as possible. This article describes the Hopnomic technology introduced by Steinecker GmbH in 2020, a new approach to increasing efficiency in hop utilization.

We can imagine that perhaps a few of the regular readers of this engaging periodical might be waiting for their strike liquor to heat up in preparation for mashing in. Perhaps, part of their routine might be to peruse this issue’s pages over a coffee while they wait. They might also want to begin casting a glance over their latest malt analysis to find what might be entered under the rubric of ‘gelatinization’, which could include ‘onset temperature’, ‘peak temperature’, ‘end set temperature’ and/or ‘pasting temperature’. One would do so in order to observe whether the old tried-and-true mashing regime might need to be tweaked with that new lot of malt that just arrived.

Synergistic effects and opportunities | Digital transformation is rapidly changing the brewing industry. How can breweries ensure their production is more efficient, sustainable and future proof? Following the merger with Schneider Electric, BRAUWELT International spoke to Jürgen Wölfl, Vice President Proleit Software Services, and Frederic Vanhove, Global Head of Sales at Proleit, about innovations, modularity and the synergistic effects that result from the collaboration.

Important control elements | The brewhouse is at the heart of beer production. A boiled, sterilised and hopped sugar solution is prepared from water, malt and hops, this is then fermented by yeast. Problems relating to water, malt and hops can often be easily remedied by optimising operation, including grinding, by adjusting the mashing process and wort boiling.

Ageing-relevant aldehydes | Ageing stability of beers pose a major challenge for brewers. Though many influencing factors such as heat or oxygen exposure are known to be beer ageing factors, there are still some unknown variables at work. In cooperation with 21 breweries, the Weihenstephan Research Center for Brewing and Food Quality has carried out tier monitoring from malt to wort and compared ageing-relevant aldehydes with the sensory characteristics of fresh beers and their ageing indicators.