Haze stability | Consumers apply high sensory standards to alcohol-free beer which is becoming increasingly popular. In order to obtain a typical beer taste, alcohol-free beers produced using different processes are usually blended, often jeopardising haze stability. The effect of adding polyvinylpolypyrrolidone on haze stability of the alcohol-free beer brewed in a specific brewery was tested.

Filter aids | Filtration is an essential process step in the production of beer. It serves to separate unwanted solids from liquid to safeguard the microbiological and physical-chemical stability of the end product. Besides extending its shelf life, precise filtration also contributes to a beer’s sensory purity. Precoat filtration with diatomaceous earth in particular has established itself as a proven method here, as it enables a high filtration rate while ensuring gentle handling of the product.

Various advantages | Eliminating the need for a cold maturation phase in beer production offers various advantages beyond energy savings. It can lead to shorter processing times and reduced tank residency, potentially resulting in cost and space savings. However, the benefits of skipping cold maturation should be carefully weighed against the advantages provided by traditional cold processing methods.

Success story | Filtration is actually an unnecessary process step, since unfiltered beer tastes just as good as filtered beer. In 19th century brewing literature, filtration is not mentioned at all. However, this would change after Lorenz A. Enzinger invented the universal filter. This article offers a review of the history of filtration, in particular the development of the diatomaceous earth filter and its further development after the Second World War by Albert Moll in Switzerland.

Fully automated | Brewery owner Jörg Gundel gets straight to the point: “Small breweries with just a few employees must automate when and wherever they can.” Jörg Gundel is the owner of Brauerei Gundel in Barthelmessaurach near Schwabach in the Nuremberg region of Bavaria, Germany. He brews around 2500 hectolitres of beer a year and with 13 different styles offers a broad product spectrum that also includes seasonal specialities.

Experimental Analysis | Technical advances in reducing the amount of caustic being carried over from bath to bath in bottle washers has had a positive effect on energy consumption, as well as on chemical and freshwater usage. As the result of several different measures, the carry-over between baths has been reduced from 50 ml/bottle to approximately 12 ml/bottle today. In the past, the primary caustic bath(s) were topped up with water, but now the caustic concentration is maintained through the gradual addition of a caustic solution.

Microbiological stability | Microfiltration using membrane filter cartridges is a method of protecting beer against microbial spoilage by reducing yeast and bacteria, achieving the desired microbiological stability of the finished product [1]. In this article, the authors introduce microfiltration, outline the theoretical background, and confirm the safety of final filtration as replacement for pasteurization.

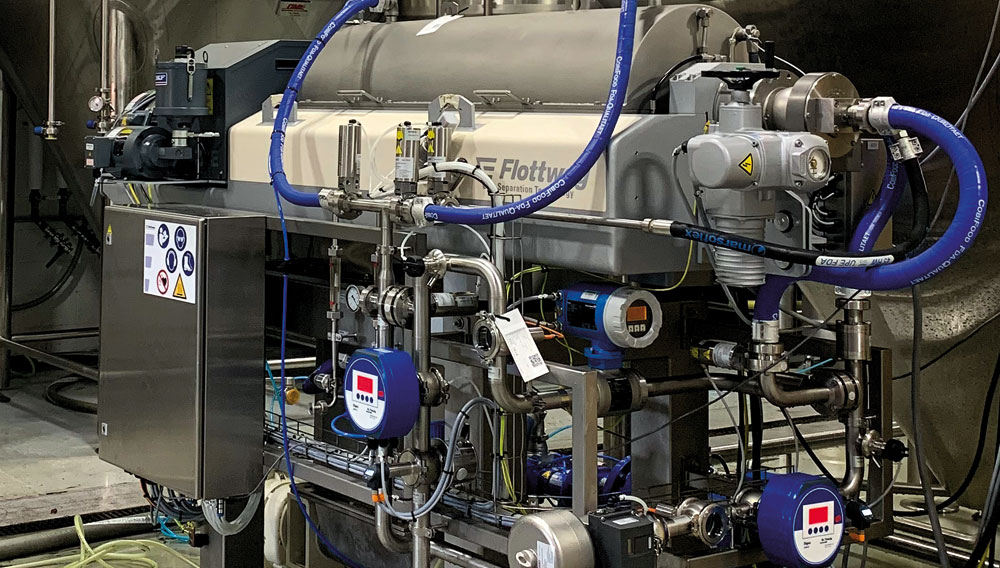

New technology | Product losses in the brewing process can be minimized, and breweries are keenly interested in reducing these losses not only to conserve resources but also to save money. This article will explore three process steps where considerable losses are incurred in the brewery, on both the hot and cold sides of production. The options for achieving a more effective process design through the use of decanter centrifuges will also be discussed.

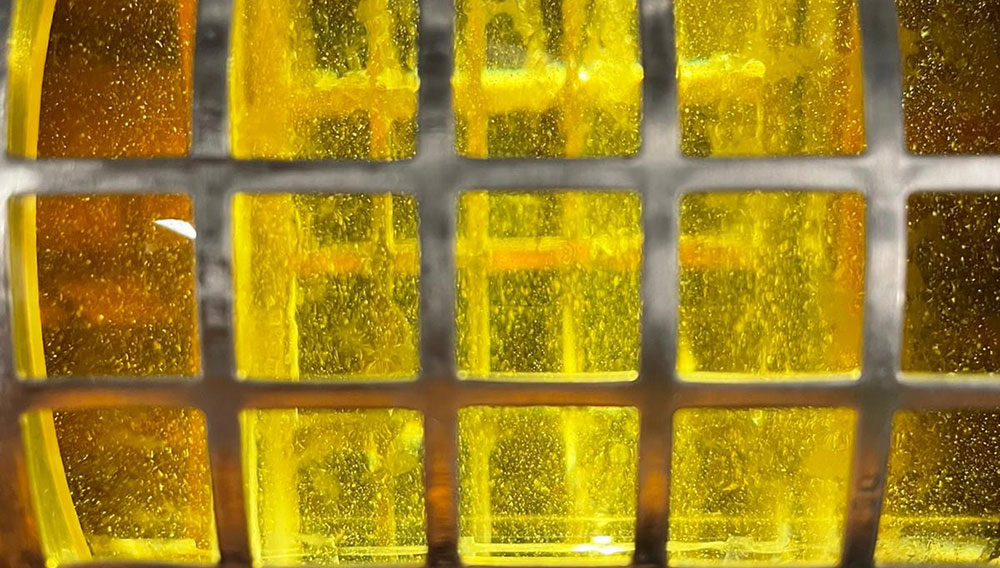

Further innovation | BrauKon GmbH, a globally renowned brewery equipment manufacturer, operates its own 50 hl brewery, Camba Bavaria, in Seeon, Bavaria, in addition to fabricating its own equipment. This combination of engineering and brewing under one roof is unique: 120 employees, 36 of them brewmasters and engineers, test and optimize all BrauKon products in the process of brewery operations. The equipment manufacturer, which claims to be the market leader in hop technology, has already launched the second generation of its successful cold hopping system, the “HopGun® 2.0”.

Mash filtration | Productivity of a brewery may be considerably compromised by lautering performance. In order to counteract inefficiencies and accelerate the process, a new process strategy was investigated in the context of a research project at the Department of Process Systems Engineering. In a two-part article, we will present the theoretical approach, use of packing and its application in a practical test on a laboratory scale.

Unique character | Brewers of craft beer are creative and know exactly what they want – unique beer that has big taste and lots of charisma. There is no way they would be able to meet these special requirements without the key role that filtration plays in the brewing process. The chosen filtration process can have a heavy influence on the turbidity, color and taste of the beer – as you will see in this fifth and final part of the series about filtration in breweries.