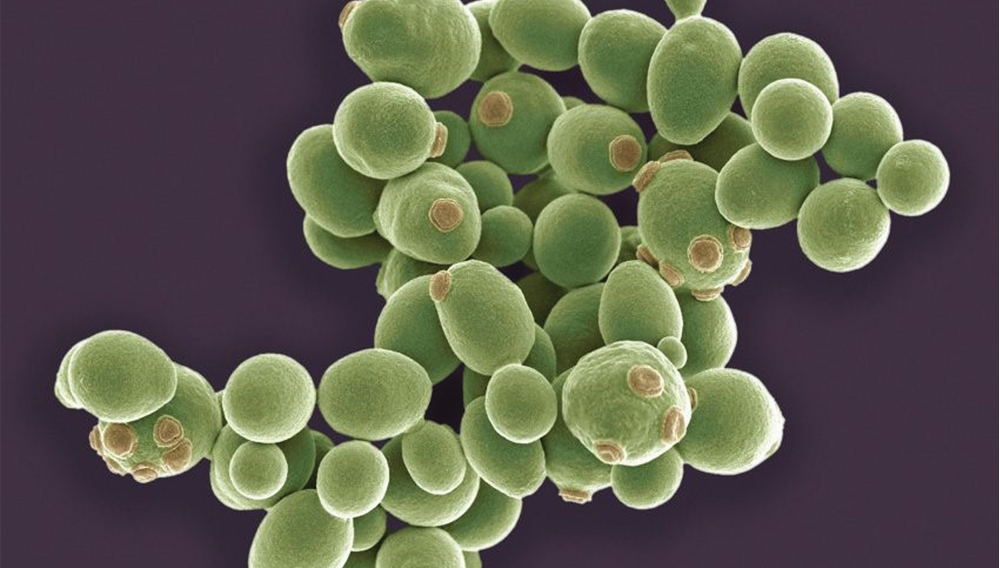

Key to beer quality | At first glance, handling and the role of yeast in a brewery seem to be easy to deal with: yeast ferments the sugars of the wort, producing alcohol and CO2 in this process.

Yeast can be harvested and recycled. When examined in more detail, matters become more complicated and have a much stronger influence on beer quality than generally assumed. As such, handling and a proper understanding of yeast is a reflection on beer quality.

The Fareham-based group acquired on 1st March Keystone Filter, a division of CECO Environmental Corp (CECO). The group has acquired the goodwill, business and trading assets of Keystone for cash.

After the fusion of Bucher Filtrox Systems AG and Bucher Unipektin AG at the beginning of 2017, a new department – Competence Center Filtration – was founded.

The Central European Commission for Brewing Analysis (Mebak) held its 90th general meeting in Linz (Austria) in October 2017 at which it agreed to fully revise the guidelines for control of brewhouse operations.

Advantageous process | Cold stabilisation of beer, also referred to as sterile filtration, can return significant cost savings over pasteurisation. In addition to providing an increased level of microbial security and better protection of beer quality, it is by far the most efficient process to operate in comparison to pasteurisation from a cost perspective. These cost savings, whilst significant, may not be widely understood or appreciated in what has traditionally been a conservative industry. Given the challenges facing brewers today, this article will share insights into the four main areas where cold stabilisation returns significant cost savings over flash pasteurisation.

Development of the new Nessie by Ziemann lautering system for mash separation is an interesting innovation for the overall techniques and technology of beer production. This paper will present the technological contexts and impacts on surrounding unit operations as well as the effects on wort quality, the ultimate outcome of brewhouse work.

The Filtration Division of the power management company Eaton has developed a new BECO filter cartridge range that can be combined to provide effective pre-filtration and final filtration for stable and bright beer.

In the first article of this series, published in BRAUWELT International No. 3, 2017, equipment and the Nessie by Ziemann mash filtration procedure were presented. Part 2 considers the effects of the novel wort composition on hop dosing. For this purpose, individual wort parameters and their effects on hop yield, an experimental test series of the disperse system and alternative wort treatment processes are described in more detail.

With Nessie by Ziemann®, a new lautering unit, intended to change in a sustainable way traditional brewhouse tasks, was presented at the BrauBeviale 2016 in Nuremberg, Germany. BRAUWELT International will be introducing this technology in a series of articles treating all relevant aspects. Part 1 describes the objectives of this development, the actual procedure and the equipment setup. The following articles will be introducing the technological implications on lautering, as well as additional developments for the upstream and downstream process steps.

Flash pasteurisation (FP) of beer is an important tool for reliable preservation. Combined with a hygienic filler, it is a gentler alternative to tunnel or chamber pasteurisers. The stabilising effect on haze and flavour of FP is becoming increasingly more important. Existing pasteurisation units (PUs) define the dimension of hot holding zones (30 sec) and temperatures (64 - 72 °C). The question arises: are these conventional parameters, using available analytical possibilities and technological objectives, really the optimal solution?

Increasingly, the traditional “beer keg” is being replaced by tank beer delivered by a tank truck. This way, delivering beer is safer, more efficient, much more cost effective and reduces the physical strain often experienced by drivers and catering staff.