Brewer’s yeast | The challenges brewers are facing require innovative business concepts. Re-use of secondary streams offers promising sales potentials. The startup ProteinDistillery uses a novel approach in order to produce vegan proteins from brewer’s yeast for the food industry.

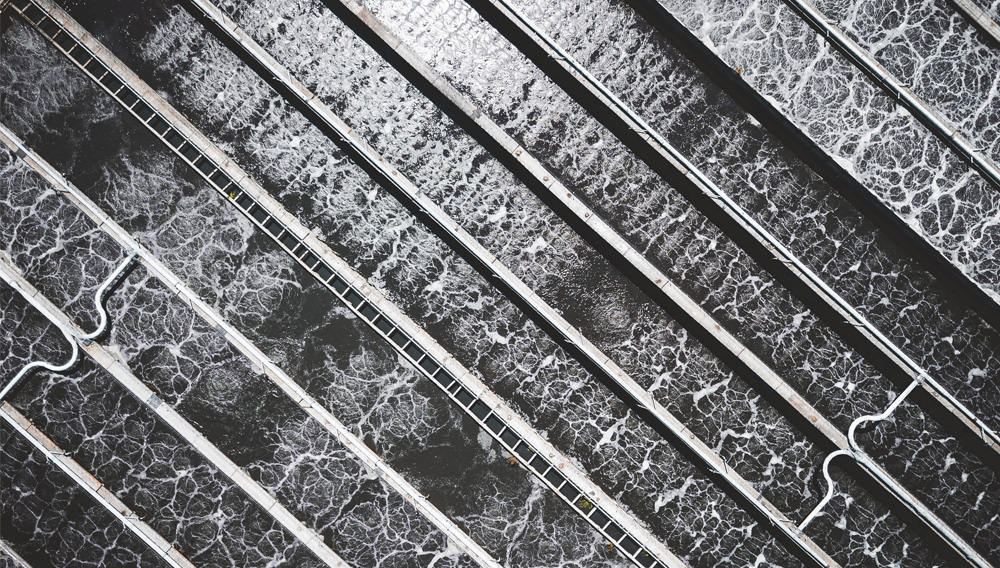

Intelligent wastewater cleaning | The development of bioelectrochemical systems for the recovery of process water permits integrated media and energy generation while simultaneously treating wastewater. This topic is addressed in a project entitled “Intelligent, hybrid, autarchic, bioelectrical systems for the generation of energy and media in the brewing industry” (I_habS).

The alcohol-free beer trend | After almost 30 years the Bavarian State Brewery Weihenstephan has invested in a new de-valcoholisation plant. This sets the oldest brewery in the world up for the future and enables it to perfectly cater for the growing demand for alcohol-free speciality beers. Greater productivity, flexibility and the use of cutting-edge technology were what triggered the decision to place the order.

Reducing greenhouse gas emissions | Facing up to its entrepreneurial responsibility for today's society and succeeding generations, the Krones Executive Board has adopted a new climate strategy. It includes a comprehensive package of measures aimed at reducing greenhouse gas emissions across the Group.

The Bühler Group has set itself the ambitious goal of reducing waste as well as water and energy consumption in its customers’ value chains by 50 % by 2025.

The European recycling industry is going to miss a 2025 target for recycling PET bottles unless there is a reversal of the slowing growth rate in recycling, according to a new study by ICIS on the 2018 market. The study also found evidence that bottle-deposit schemes are working better as an incentive than market prices for recycled material.

Energetic optimisation | The first part of this article (BRAUWELT International No. 5, 2018, pp. 345-349) discussed the question of what kind of process design is the most suitable one for a brewery. In conclusion, clear advantages of the batch process over continuous process variants were found.

Krones AG, Neutraubling, Germany, and Erema Engineering Recycling Maschinen und Anlagen GmbH, Ansfelden, Austria, have agreed to collaborate in the field of PET plastic recycling. The aim of this alliance is to incorporate the technical expertise of both companies into the planning and design of PET recycling lines and indeed complete factories, so as to be able to offer clients from both the beverage and PET recycling industries an optimal line or an entire factory.

Many companies in the food sector have switched over to contracting models in order to implement technically and economically optimised water treatment with energy recovery. The Oettinger family business, with head offices in Oettingen Bavaria, currently represents just such a case. The company produces and markets a wide range of beer and non-alcoholic beverages.

ttz Bremerhaven is a provider of research services and performs application-based research and development. Under the umbrella of ttz Bremerhaven, an international team of experts is working in the areas of food, environment and health.

Part 1 described the structure of microorganisms (MO) as well as possibilities of reducing their hazard potential for drinking and process water, air and product in breweries to a minimum or to zero. Disinfection by chlorination and treatment with chlorine dioxide are also covered [1]. In Part 2, further disinfection methods as well as use of peroxy compounds and UV treatment are described. In addition, the action of disinfectants on various materials and possibilities to avoid corrosion are presented. The tenet should be to match water quality and disinfection processes.

The overall recycling rate for aluminium beverage cans in the enlarged EU 27 including EFTA countries and Turkey further improved in 2008 and stands now at 63.1 percent. It has improved from 61.8 percent in 2007, respectively 57.7 percent in 2006. This 5.4 percent increase over the past two years represents an impressive extra carbon footprint saving of more than 310,000 tons of CO2 equivalents.