Quality assurance | Phenolic aroma compounds can significantly impact the aroma profile of beverages. Depending on beer style and consumer expectations, they are regarded both as valuable aroma compounds as well as off-flavours. The latter case is referred to as phenolic off-flavour (POF).

Food safety | Breweries that want to trade nationally with private label products and at international level with brand-name goods or handle sub-processes for other companies need certification according to a food safety standard as their entrance ticket. Food certification systems help companies to comply with legal regulations and meet customer-specific requirements. At the same time, they can also be used as strategic tools to improve corporate processes and minimise risk.

Decision-making tool | Choosing the right sampling device and opting for a specific sampling system depend on a number of different factors. These can vary depending on the area of application and respective requirements. This article examines the key criteria for sampling systematically and in detail.

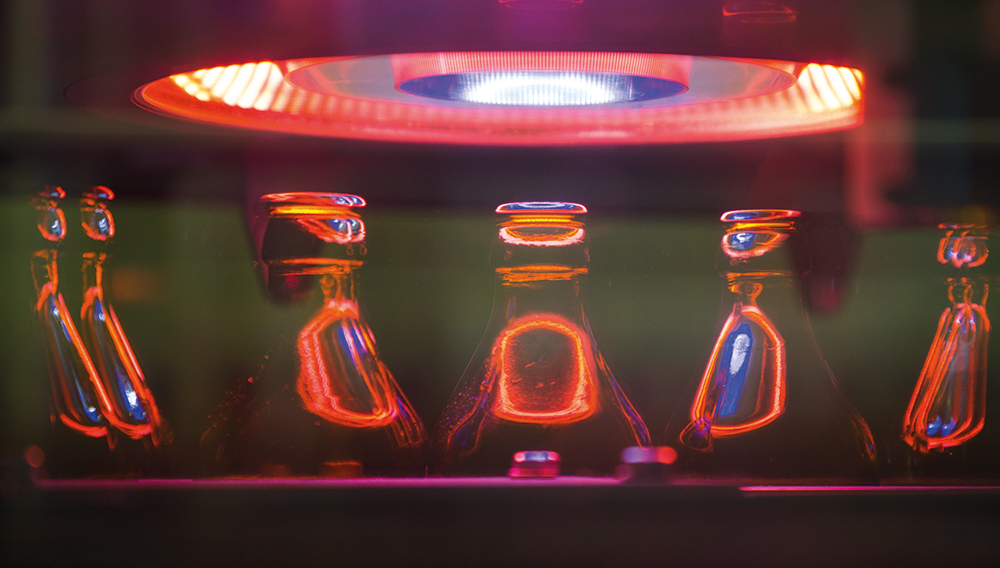

Inspection | When inspecting empty bottles, one of the key factors is the perspective. The view “from above” of the bottle neck or into the container is particularly important for many applications.

The miho Vidios® SC operating system has been extended with a Top-Cam family. This product family currently includes eight models. With a multitude of camera-lighting-systems, these are assigned for particular purpose

Most frequent beer spoilers | Analysis of findings at the Research Centre Weihenstephan for Brewing and Food Quality, TU Munich (TUM FZW BLQ) about beer-spoiling microorganisms provides a good overview of the status quo, distribution, seasonality and frequency of beer-spoilers.

Much can be achieved | Microbiology does not follow textbooks – and certainly not what we would like it to be. Biology involves evolution, adaptation and sometimes sheer luck. “That’s simply impossible. I would really like to detonate this operation.” This or similar statements are sometimes made by owners, managers or brewmasters when they are standing with their backs to the wall. This is mostly caused by microbiological problems in the finished product.

Most frequent beer spoilers | Analysis of findings at the Research Centre Weihenstephan for Brewing and Food Quality, TU Munich (TUM FZW BLQ) about beer-spoiling microorganisms provides a good overview of the status quo, distribution, seasonality and frequency of beer-spoilers.

Kombucha research | In three decades, kombucha transitioned from home-made production to a trending mass-produced fermented beverage associated with wellness and health [1, 2]. During the last five years, the global kombucha market has experienced intense growth (from 2 billion USD in 2019 to 2.97 billion USD in 2024) [3]. So did kombucha science, although it focused heavily on uncovering potential health effects, which is dissociated from the expectations of kombucha producers who keep putting efforts on quality improvement to boost market development [4, 5].

Predictive failure prevention | Do you want to hedge your bets and hit the jackpot? Then maybe you should consider making use of a tool from the extensive quality management toolbox: FMEA. Failure mode and effects analysis is now slightly out of fashion and, as far as we know, barely used in the beverage industry – if indeed at all. If you study it in greater depth, however, you soon realise its potential.

Quality control | AI, or artificial intelligence – this buzzword is currently being discussed in many contexts. Opinions range from outright rejection to the expectation that AI will do everything better. In fact, it has been observed in many discussions that this complex topic is often only considered in general terms, and the specific details are frequently ignored. Therefore, we will try to take a closer look at the topic for applications of automatic quality control during beverage filling, in particular for empty bottle inspection.

Structured and focused | In the first installment in this series (BRAUWELT International no. 5, 2024), we introduced and outlined the nine senses humans possess that are relevant for conducting the sensory analysis of beer. Furthermore, we explained their significance and the roles they play in physiologically and indeed psychologically motivating a person to drink beer. This installment continues with a discussion on how to optimize the sensory quality of a selection of beers and to successfully develop a strategy for product innovation in a targeted manner.