Barrel ageing | In recent years, maturation of beers in wooden barrels is becoming an interesting avenue for breweries to expand and refine their beer portfolios. Especially in the craft beer sector there is an increasing consumer demand for more complex flavours and aromas, many of which can be obtained through barrel ageing of beer. However, microbial spoilage of the barrel has to be effectively controlled in order to ensure consistent product quality and reduce profit losses.

CO2 quality | Many breweries purify their fermentation carbon dioxide and reuse it. Unfortunately, in conventional CO2 purification plants, not all flavour substances potentially still present are removed and remaining ones could be carried over into the beer when purified carbon dioxide is reused. Carry-over of off-flavour impurities may be prevented by installing the MPlus PC02 from Parker, thus extending the recovery plant.

Foam stability | Various physical phenomena can be observed in beer foam. Foam membrane strength is an important factor influencing head retention. When comparing various foam analysis methods (Sigma, NIBEM and FCT developed by us), it was found that NIBEM and FCT were more sensitive in determining foam membrane strength than Sigma. In this article, the importance of the composition of hop bitter acids for foam membrane strength and visual foam stability is described. It summarises some research results which have already been published in BrewingScience, 2021, issue 6: November/December.

Development environment | In October 2020 Alfa Laval opened its new Fluid Handling Application & Innovation Centre in Kolding, Denmark. At the centre that covers 1600 square metres, users from the food and pharmaceuticals industry can test their processes and the impact these have on their products under real conditions before deciding to invest. BRAUWELT spoke to food and water division manager Christian Garbers at Alfa Laval Mid Europe about the options and opportunities the facility offers its users.

Colloidal stability | The colloidal stability of beer is an important criterion in filtered beers as any haze or flocculation is not accepted by consumers. For this reason, timely knowledge of the state of the colloidal stability is not only of interest to export beer breweries, but also to small and medium-sized brewing companies. As existing methods of analysis either only take some of the beer constituents involved in the formation of haze into account or require long analysis times, a new rapid measurement method for checking the colloidal stability was developed.

Reaction kinetics studies | Gentle handling of beverages during the preservation steps is becoming increasingly important, particularly for products with sensitive ingredients. Relationships between chemical changes and microbiological deactivation could have the potential of retaining valuable ingredients, e.g. L-ascorbic acid, in juices.

Analytics of gushing | In ongoing research, TU Munich is investigating the physical processes during formation of gas bubbles in liquids prone to gushing. Part 1 of this two-part series of articles described the theoretic fundamentals and the measuring instruments developed (BRAUWELT International no. 2, 2022, pp. 96–99). Part 2 presents examples of results of associated experimental studies.

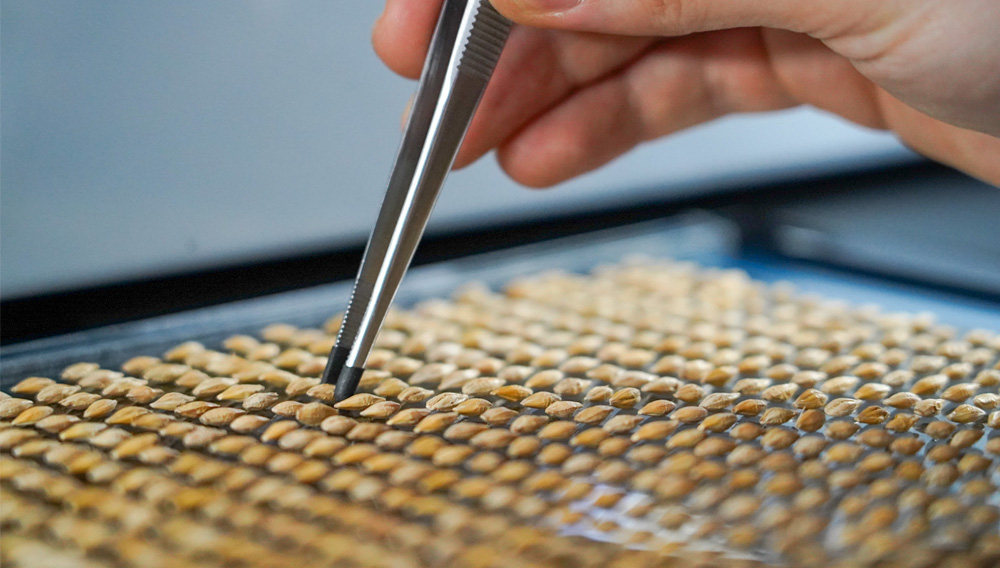

Assessment solutions | ZoomAgri, a technology company founded in 2017 in Buenos Aires, Argentina, provides assessment solutions for agricultural commodities using AI, computer vision, and IoT. It offers various products for malting barley variety recognition, and for recognizing the physical quality of grains and oilseeds such as corn, soybeans, wheat, and malting barley in real time, at location and against very attractive prices, leading to a higher quality malt and beer.

Always up-to-date | “Monday moaning meetings” – the start of the week for breweries is frequently met with a groan. It is when the folders and reams of data come out. As one of the breweries pioneering a digital innovation developed in a GEA design sprint, Störtebeker Braumanufaktur can in the future dispense with this paper chaos. GEA InsightPartner Brewery provides real-time data, helping quality control and making the Stralsund-based brewery faster, more productive – and smarter. The tool not only gives Störtebeker an intuitive overview of performance data, but also something even more precious: time.

Gently mixing products | This is a topic under perpetual discussion. Economic comparisons, in particular, form the basis for making decisions when choosing a process or when considering the investment required to implement a continuous process. Aside from economic considerations, aspects such as the duration of the process, how well it can be automated and the level of product losses as well as the costs and labor associated with cleaning and maintenance are all very important for manufacturers concerned with upholding high quality standards, since these factors affect the quality and influence the final product during the process.

Hygienic challenges | For years, alcohol-free beer has enjoyed a steady increase in popularity. This is not only thanks to drinkers taking various social aspects and health concerns into account; it’s also a result of the constantly improved quality of these beverages. Alcohol-free beer is almost exclusively sold in small containers such as bottles or cans. Dispensing it from barrels is rare; even less common is the distribution of non-alcoholic beer in tanks. However, the wish to be able to also offer customers this relatively new type of beer on tap is growing.