Yeast recycling | Yeasts are usually used for one fermentation cycle in industrial fermentation. In the brewing industry, however, yeasts are recycled several times, also as a result of a continuous succession of production processes. Consistent and, in particular, reproducible fermentation results have to be obtained. Optimal yeast management is required in order to achieve this objective. Moreover, the number of cycles is crucial for fermentation performance and depends on the yeast strain as well as on the experience and philosophy of the brewmaster.

Microbiological analysis | In Part 2 of this series of articles (BRAUWELT International No. 4, 2018, pp. 274-276) several current QA documents that breweries have to treat as controlled documents were presented, along with a sample plan and some simple analyses that a brewery should carry out, such as organoleptic and visual checks. Filterability of beer by means of simple analyses was also discussed. In this part, microbiological analyses of beer during production are described. In addition, possibilities for reducing i.a. losses in the brewhouse are considered.

The biotechnology company now offers two new real-time PCR tests for the detection of the most important spoilage yeasts in beer, alcoholic mixed beverages and soft drinks: the foodproof® Spoilage Yeast Detection 1 + 2 LyoKits.

As part of a longstanding partnership, measuring instrument specialist Anton Paar and statistical process control (SPC) solutions provider InfinityQS® have launched a guide for setting up the interface between Davis 5 and Enact® or ProFicientTM software.

QA controlled documents | In Part 1 of this series of articles (see BRAUWELT International No. 3, 2018, pp. 218-221), the historical cooperation between brewery chemists, microbiologists or laboratory technicians (“QA”) and master brewers, process managers and packaging line managers (“master brewers”) was discussed. It was found that QA and master brewers need each other, but also that they are sometimes not aware of this.

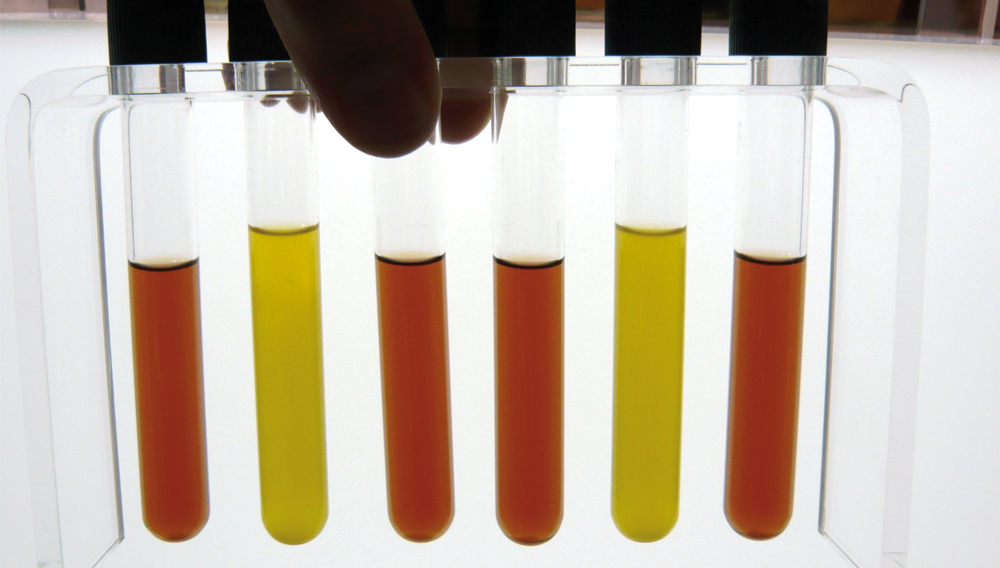

Optimised | Every brewery aims at producing microbiologically perfect beer. For quality assurance, rapid, safe and simple methods are needed, in particular for detection of traces of beer-spoilage bacteria (BSB). Enrichment in the new, ready-to-use NBB®-PCR broth supplied by Döhler GmbH, Darmstadt, in combination with a PCR detection system, provides an optimal solution.

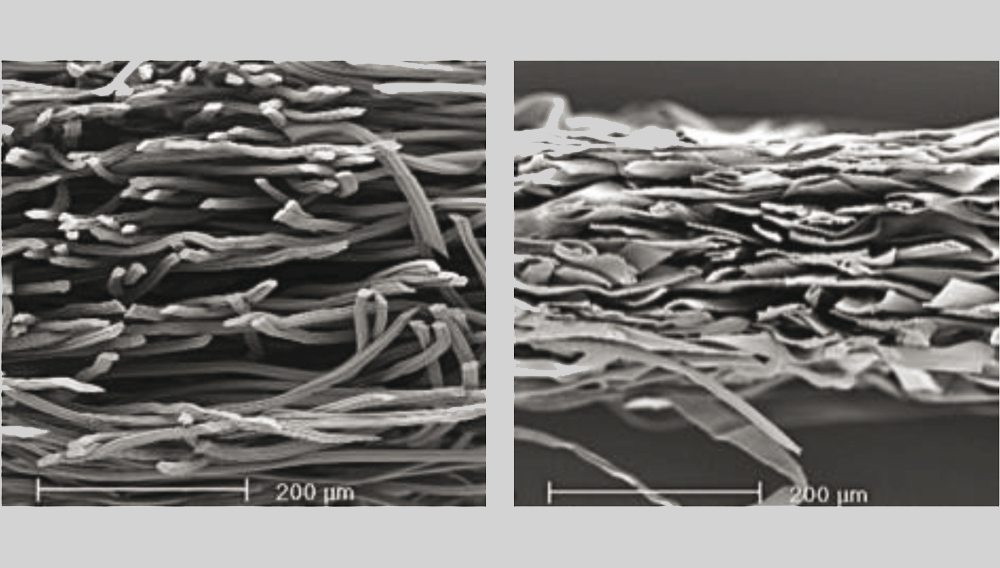

Controlled Compression | Fibrous filter aids such as viscose and cellulose differ significantly from kieselguhr or perlite in that they form a compressible filter cake during precoating onto a carrier element. Depending on compression, permeability and porosity of the cake vary. A novel process for filtration using fibrous filter aids takes advantage of this property.

The “Oscars” for Beer | The European Beer Star is considered to be one of the most successful and established beer competitions of its kind. Since its inception, the number of breweries entering beer has been growing steadily along with the number of style categories. To manage such an event, the organization has to be well thought out. After all, all of the beers in the competition must not only arrive in the best possible condition, they must also be coded so that the members of the tasting panel do not know who brewed them. How does it work? We visited Doemens Academy in Gräfelfing, Germany, to have a look behind the scenes at the preparations leading up to the European Beer Star.

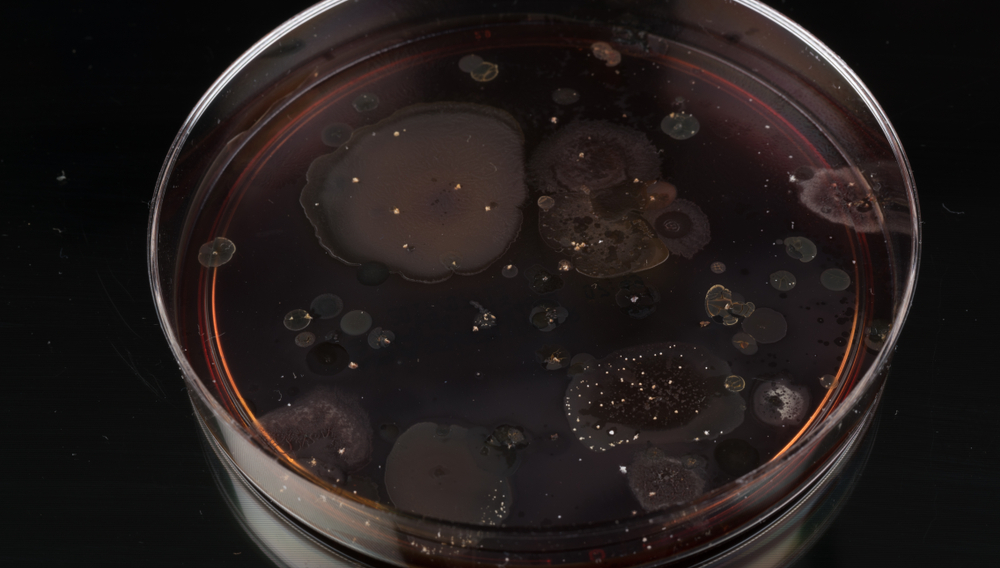

Attractive alternative | Mass spectrometry profiling is an emerging technology for the identification of spoilage microorganisms in breweries, enabling high throughput identifications to the species level without the need for specialist personnel. Here we provide a detailed cost analysis, which demonstrates a significantly lower per-sample running cost as compared to polymerase chain reaction (PCR). This renders mass spectrometry profiling as an attractive alternative for microbial identification in breweries.

Wort preparation is at the heart of beer production, yielding wort for fermentation from water, malt and hops natural raw materials. The fourth part of this series of publications provides an ultimate answer to the issue of the best process for removing DMS from wort.

Freshly tapped beer is something special, but there are always certain faux pas to be avoided at the draft beer bar. Since aroma and flavor are the primary criteria for assessing draft beer, this article provides an overview of possible faults which can be introduced into the product once it has been connected to a dispensing system or through contamination by certain microorganisms.