Hygienic challenges | For years, alcohol-free beer has enjoyed a steady increase in popularity. This is not only thanks to drinkers taking various social aspects and health concerns into account; it’s also a result of the constantly improved quality of these beverages. Alcohol-free beer is almost exclusively sold in small containers such as bottles or cans. Dispensing it from barrels is rare; even less common is the distribution of non-alcoholic beer in tanks. However, the wish to be able to also offer customers this relatively new type of beer on tap is growing.

Asset control | Like all breweries today, BGI Ethiopia, Addis Ababa, Ethiopia, has been continuously facing significant financial losses related to the loss of their kegs. To resolve the problem, they engaged experts in breweries automation from Montelektro and their partners from 8Sigma, whose expertise is developing Manufacturing Execution System (MES) and similar Industry 4.0 solutions.

Overview | This article is an abridged version of the scientific paper “Fermentation and Spoilage Yeasts and their Relevance for the Beverage Industry – A Review” which appeared in BrewingScience in 2012 [13]. At the time, the article provided a summary of the latest findings on the subject of harmful spoilage yeasts and wild yeasts and still serves as a reference in the event that problems are encountered with these microorganisms.

Beer quality | Oxygen impacts negatively on beer quality in terms of flavour, stability and quality. No oxygen, if at all possible, should get into the product after fermentation. For this reason, residual oxygen is monitored in the trace range at critical locations with in-line sensors or portable devices.

The new -omics technologies | Over the last few decades, we have all experienced the benefits of increased computer power, either in our daily lives or at work. The sheer volume of data that can be generated has also required increased storage capacity and new cloud-based applications. Blessing or curse, the reality is: we rely on these on a daily basis. Even in the malting and brewing industries, we are facing ever-increasing amounts of data, requests for more data, and faster access. The growth in data is down to a number of technologies such as metabolomics and proteomics which can provide data on hundreds to thousands of compounds. This review is a helicopter view of these two technologies being used to profile raw materials, brewing, and beer quality in extraordinary detail.

Quality assurance | Dry hopping has become an essential technique in beer brewing, designed to create the aroma of a beer and to produce pronounced, typical beer styles. This excerpt from an extensive research project provides some insight into the chemical-physical changes associated with dry hopping.

Beer color equations | This is the second article in a three-part series about the challenges of specifying beer color at the recipe design stage, as well as measuring it after the beer has been brewed. It examines the most common equations currently in use by brewers around the world for specifying beer color before the brewing process begins.

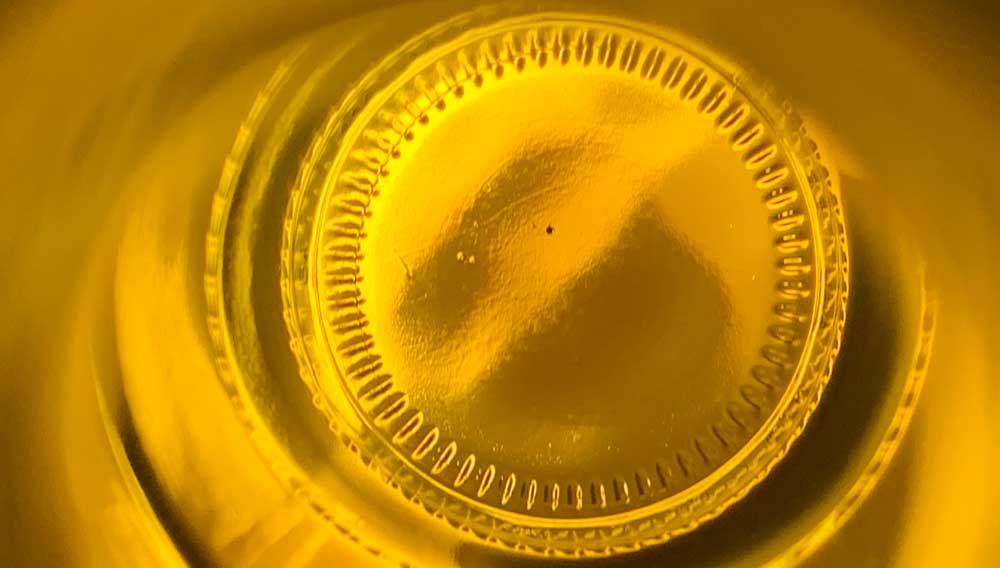

Inspection of empties | Regular verification of cleaning performance of bottle washers in breweries is important in order to ensure perfect product quality and product safety. This is the reason why the Research Center Weihenstephan for Brewing and Food Quality, Freising, Germany, in cooperation with five breweries, validated a test series with standardised contaminated bottles. This should enable breweries to carry out their own checks.

Measuring beer color | This is the first in a three-part series of articles about the nature of beer color, as well as the difficulty of accurately quantifying color both at the recipe design stage and in the finished beer. Part 1 explores the nature of color in general and the historical evolution of beer color measurements. Part 2 examines the differences and similarities of the most common equations used by today’s brewers around the world for calculating beer color – not after the fact in the laboratory – but in advance during recipe formulation. Finally, part 3 analyzes three test beers brewed specifically for this study. It compares the color predictions for these brews made by the different beer color formulae outlined in part 2 to the actual color measurements of the same brews made in the laboratory. This comparison allows practical brewers to select which equation might be the most advantageous for them to use at the recipe design stage.

Feel the process | The packaging of products is something that, apart from the beer itself, speaks to the consumers. Packaging is present in all parts of the production process, involves the majority of plant departments, and runs through all stages of the supply chain. Therefore, understanding what our bottles and cans experience, or in human words: what they “feel” in the process, turns out to be crucial to the brewing businesses and – as various real-life cases show – leads to wonderful benefits. Especially, when the “feeling” is translated to data.

Ageing behaviour | Forced ageing at 40 °C is one of the most common methods for assessing sensory stability of pale lager beers. However, different aroma profiles frequently arise in practice compared to natural ageing at 20 °C. The present article describes the ageing characteristics of pale lager beers during forced and natural ageing, both in sensory and in analytical terms. The contribution is based on research results that have been published in BrewingScience, May/June 2018, volume 71.