Cleaning/Disinfection

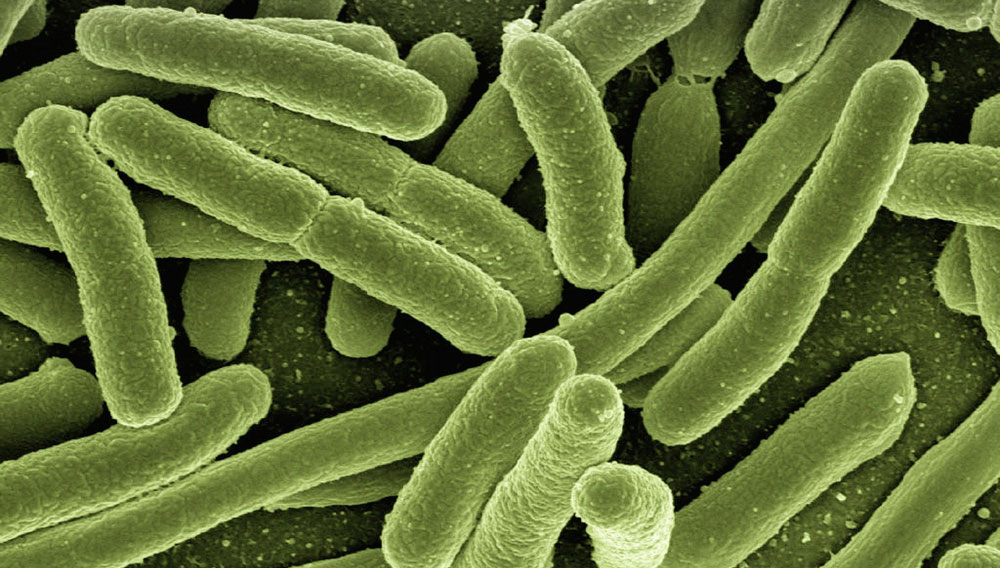

Brewery hygiene | If we look back on 50 years of brewing microbiology, we gain a number of extremely interesting insights. Can we draw a positive conclusion here or are there also negative aspects that have to be taken into account?

Quality assurance

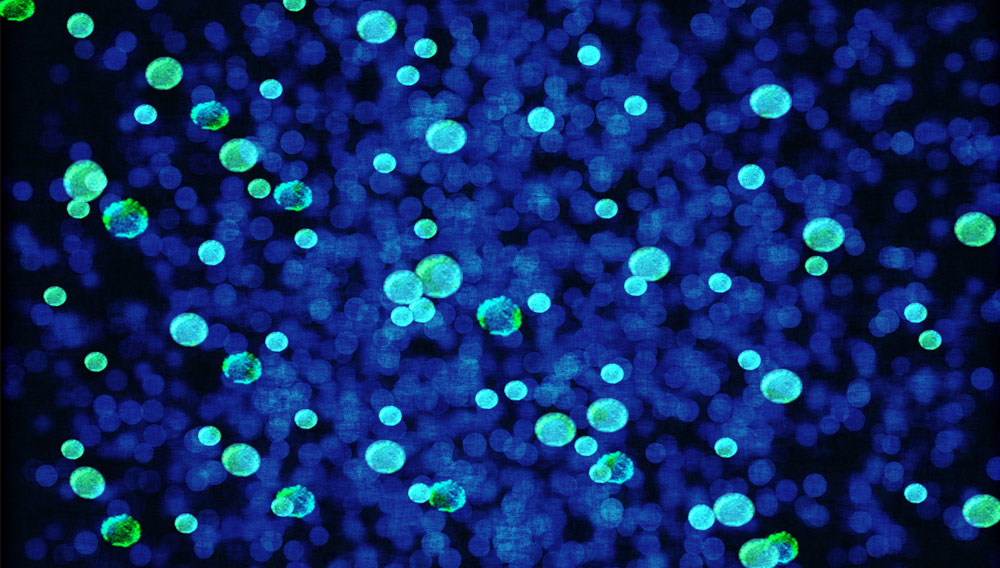

Beer-spoilage potential | In the food industry, lactic acid bacteria play a special role, they have become important both as beneficials and as spoilers. Lactic acid bacteria also have these two opposite characteristics in breweries.

Fermentation/Maturation

Practical findings | Beer loss has always been one of the biggest challenges to breweries with regard to efficient beer production and maximisation of the beer sold. Especially when making hoppy craft beers, where dry hopping is often practiced, the beer yield is drastically reduced. Thanks to the latest practical findings from a long-term BrauKon trial, the amount of beer loss can now be significantly reduced by adjusting two characteristics in the cylindroconical vessel: essential here are a special surface finish and a defined cone angle.

Fermentation/Maturation

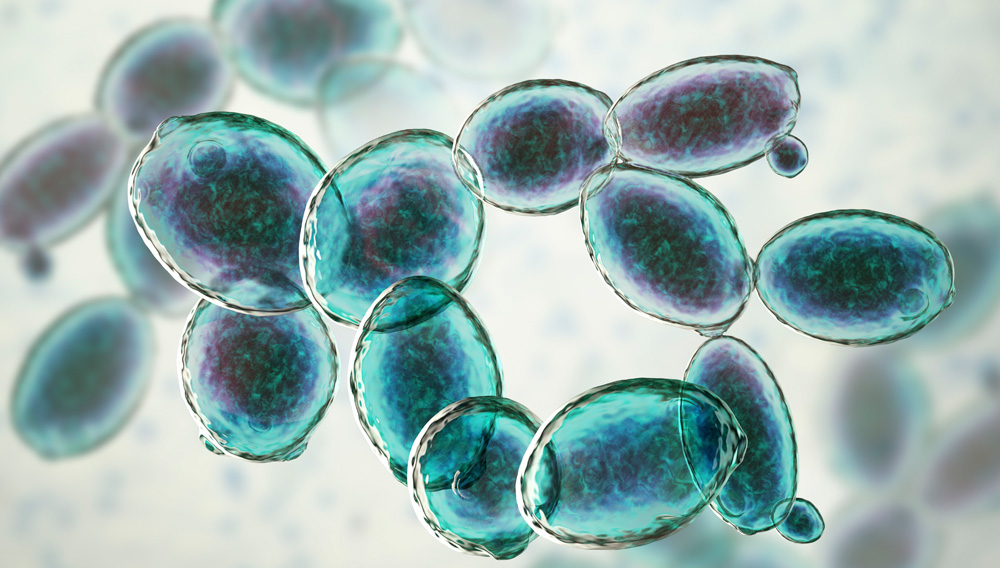

Vibrating sieve | Beck’s – the name is legend and the advertising campaign featuring the Alexander von Humboldt barque with its green sails cutting through the waves to “Sail away” familiar to many of us since 40 years. GEA project engineer Clemens Fries claims that this is “an inspiring environment in which to perform ‘minor open-heart surgery’.” Fries is namely responsible for the new special yeast sifting plant that’s now been integrated in Bremen as a fully-automatic process line.

Quality assurance

Trained senses | Is a sensory panel suitable as an “analysis instrument” for monitoring the quality of spirits? Can training a panel specifically for detecting wood-derived substances, key aroma substances, color and faults common in whiskey supplement, or even replace, laboratory analysis for measuring individual substances? Are there limits, and if so, what are they? This is the third installment in the series, which began with the basics of barrel aging in part 1 and continued with the laboratory analysis of barrel-aged spirits in part 2 [1, 2]. In this installment, the authors will consider another measuring device: human beings.

Quality assurance

Simulated barrel maturation | How do the aromas and color of spirits develop during barrel maturation? What roles do the degree of toasting and the type of wood play? What is the most practical method for determining the phenolic compounds and the volatile substances in wood, such as higher alcohols, aldehydes, esters and lactones? With gas and liquid chromatography? The authors recreated the process of aging in wooden barrels in the laboratory and analyzed the processes of extraction, color and aroma formation.

Quality assurance

For over 50 years the Central European Commission for Brewing Analysis (MEBAK®) has published methods of analysis for raw ingredients, wort, beer and beer-based beverages.

Quality assurance

Whiskey, Rum & Cognac | Which woods are utilized for wine and spirits barrels? What does toasting and charring do? Why is wood able to generate such complex aromas, and which key aroma compounds can be extracted through the maturation of spirits in barrels? In a three-part series, the authors describe the development of methods for measuring the characterization of wood-based flavors in spirits. Part 1 introduces the basics of maturation in wooden barrels.

Quality assurance

Ensuring product quality | Balancing 400 years of brewing tradition with modern tools and technologies that push the limits of production is anything but easy. Leveraging modern sensor and production technologies to measure everything from wort to bottled beer, the quality control (QC) team at Hofbräu München ensures that Hofbräu München’s beer has its expected taste, complies with regulatory standards, and meets high quality standards. And it does this with Anton Paar instruments.

On tap

Visual foam stability | The quality of beer foam depends on many factors, including initial foaming, head retention, lacing and so on. Most foam analysis methods focus mainly on head retention. Using such methods, foam membrane strength for head retention was shown to be an important aspect. Could this factor be responsible for head retention only? And what role do hop bitter acids play in this? The following article summarises some research results which have already been published in BrewingScience, 2021, issue 6: November/December.

Raw materials

A new analytical approach | The contribution of different malt types to the beer aroma is traditionally assessed by trial-and-error testing in pilot scale. In this article, we describe a new analytical method that shows promising results in predicting specific aroma properties of bottom-fermented beers based on the analysis of marker volatiles in the malt mixtures applied for brewing without the need for extensive brewing trials and beer sensory evaluation.