Best prerequisites | The fourth part of our Hygienic Design series introduces the European Hygienic Engineering and Design Group (EHEDG). The German test centre is located at the Weihenstephan Research Centre for Brewing and Food Quality (BLQ). Its particular facilities ensure that Hygienic Design assessment, so important for the brewing and food industries, can be carried out.

Beer analysis | Anton Paar is a full-range supplier for comprehensive beer analysis from one source, headquartered in Graz, Austria. Customers are empowered to measure key parameters from incoming raw materials all the way to final quality control of the packaged beverage, and also benefit from the renowned global support and service from local specialists. In this article, the company presents its newest solutions for different brewery sizes.

Structured and focused | “Sensory Beer Designing” represents a means by which the individual demands of customers and specific aspects of the market are taken into consideration during product development. It is also important that sensory quality management is placed at the forefront of quality control. This article is the first installment in a multi-part series which discusses the brewing technology options that can be employed to promote the characteristics of beer which are perceived as positive by consumers. This first installment introduces the basic concepts of sensory beer design.

Malt receipt | Analysis of malt for various qualitative analytical characteristics has the practical purpose of assuring the specified and/or required quality so that it can be processed afterwards in the brewery without any upsets. Additional information such as malt variety, malt modification or malt type (colour) can also be obtained. Despite suitably executed methodology, it is often perceived that malt analysis is viewed very uncritically, apart altogether from being judged for plausibility. Results of malt analysis are thus often interpreted inappropriately in day-to-day operation.

Inline process analyses | Seli GmbH Automatisierungstechnik has been involved especially in optimisation of production processes for quite some time. With new developments, the company was able to contribute to conservation of resources and thus protect the environment. It is not necessary to initiate new projects worth millions all the time in order to make a contribution. In most instances, the existing structure of production processes has a lot of potential to bring about major outcomes with low investment.

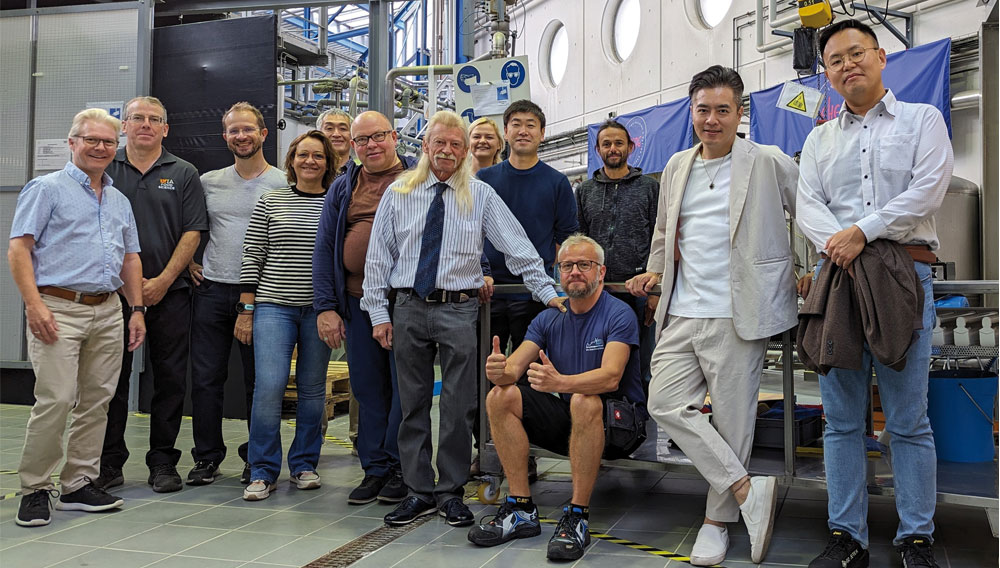

Cleanability test | A five-part series of articles covering the topic of hygienic design including fundamental explanations started in BRAUWELT International no. 2, 2024, pp. 110–112. Subsequent parts describe additional testing and certification options. Part 2 presents an assessment method being carried out by the Weihenstephan Research Centre for Brewing and Food Quality at the TU Munich in the context of a hygienic design assessment. Proof of easy cleanability is essential for beverage producers to ensure that existing plants can be cleaned reliably and thoroughly.

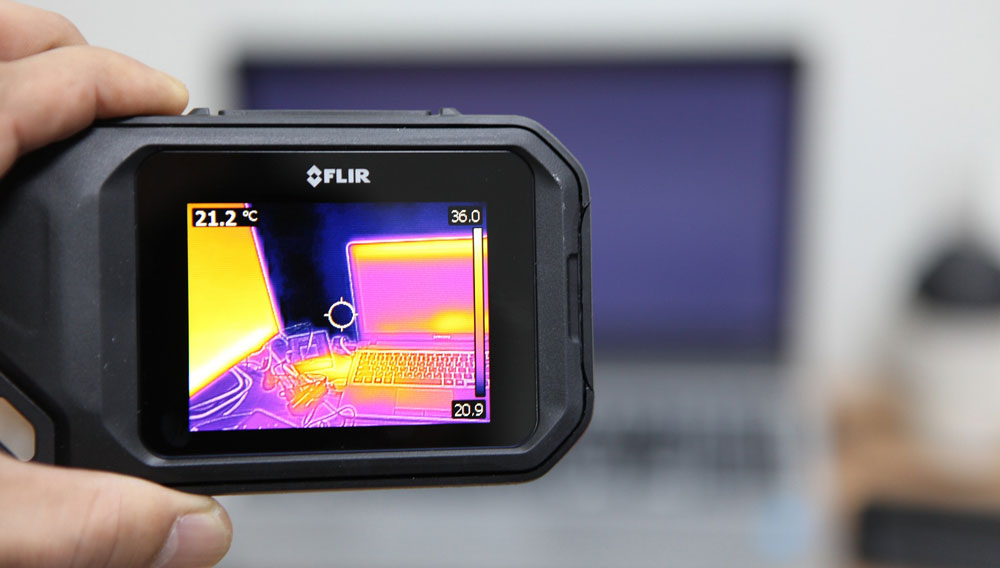

Thermal images | Thermography refers to an imaging technique that – locally resolved – makes surface temperature of objects visible. How can this be used for process and equipment monitoring in the brewing sector?

A multi-causal problem | The spontaneous overfoaming of beer or carbonated beverages after opening the bottle without any external mechanical influence such as shaking is known as “gushing”. The product return or recall actions this triggers can lead to high financial losses – and can damage a company’s image. The causes of gushing – a multi-causal problem – are still not fully understood, although much research on this subject has been carried out over the years. It is known that gushing can be caused by raw materials on the one hand (primary gushing) and by technological factors in production on the other (secondary gushing). This article presents the research results on the influence of water quality on gushing behaviour in the Modified Carlsberg Test.

Brewed to perfection | For most consumers, it would seem logical that beer could simply be brewed by following a recipe. However, a glance at the typical characteristics of a Helles-style beer reveals very narrow limits on the variability regarding original gravity, bittering units, color and aroma. Similarly, the possibilities for creativity in recipe design also appear somewhat limited. Yet this is precisely what makes this beer style so fascinating, the quality of which is largely determined by the brewing technology – or rather the art of brewing.

Food safety | Implementation of hygienic design in the beverage sector provides many benefits. When cooperating with engineers, designers and experts for food safety, companies can assure that their production facilities comply with the strictest hygiene standards and maintain quality and safety of their products.

Cleaning efficiency | Modern CIP systems are only a point of discussion when they don’t work as they should do. CIP systems provide great service for a long time without any grounds for complaint or the need for any further intervention – bar the necessary maintenance. Their degree of efficiency can decrease, however. More detailed study of CIP systems reveals that they do indeed have several weak points that can mutate into risks.