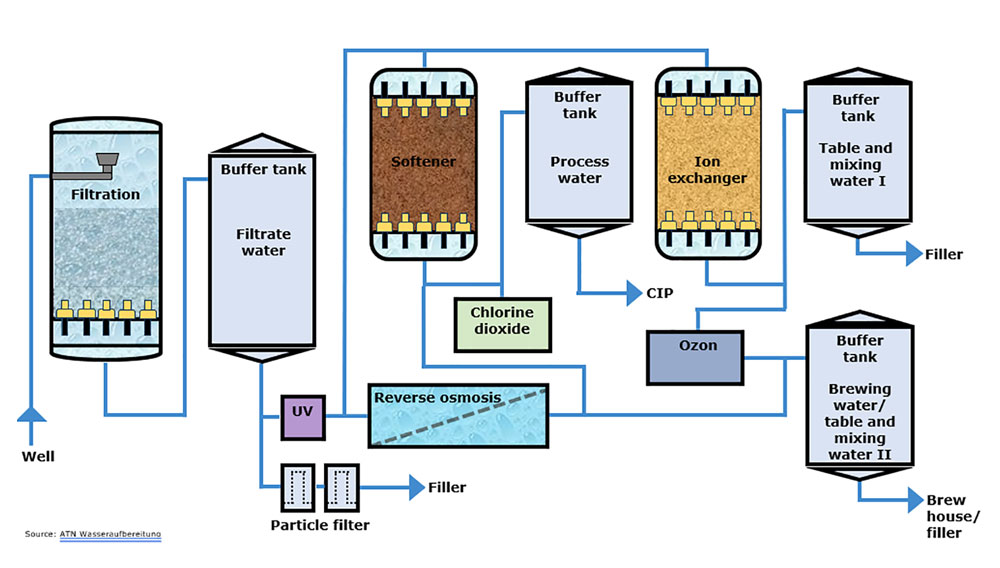

Overview | Beverage producers are constantly jostling the three prime concerns of quality, resources and time. In the face of ever-increasing cost pressure, resources and the conservation thereof are becoming more and more important. One major factor in production is water treatment. Which options are open to companies who want to save on resources in this area?

Water treatment | There was a time when water was available in unlimited quantities – at low cost. This is no longer the case. The economic efficiency of a beverage producer is meantime also measured on the basis of “water ratio”, i.e. recovery of product water. Guidelines or targets for saving raw water or for reducing wastewater are often in place. Operations feel the pressure and have to take measures for optimising this stage of production, i.e. water treatment.

Water consumption | Water is the most important raw material for the beverage industry. In many places, however, water resources are under pressure from global warming and pollution. And so, beverage makers are seeking ways to use this “blue gold” more efficiently. This article explains how they can reduce their water needs and why thermal energy plays a significant role.

Water scarcity is becoming a harsh global reality. Climate change, population growth and political instability are combining to create extraordinary pressures on this precious resource. The brewing sector is a traditionally heavy user of water in products, and in the intensive cleaning programs required to ensure the highest standards of hygiene. In this article we discuss what brewers need to know to save water and achieve their sustainability goals.

Cost-effective solutions | Where they have been hit by droughts and water restrictions, brewing and beverages operators have suffered cutbacks in expansion plans and existing production. In this article, Bill Denyer explores how they can develop cost-effective solutions for safeguarding and optimising their use of their water resource in a water-constrained world.

New technology | Beer is mostly water, and minor ionic components have a major influence on brewing and beer quality. CapDi, a new membrane capacitance deionization technology developed by Voltea, can now offer brewers an alternative to traditional deionization treatments.

Intelligent wastewater cleaning | The development of bioelectrochemical systems for the recovery of process water permits integrated media and energy generation while simultaneously treating wastewater. This topic is addressed in a project entitled “Intelligent, hybrid, autarchic, bioelectrical systems for the generation of energy and media in the brewing industry” (I_habS).

ISBT | The ISBT Connection added a new, regular section to their website where they communicate new publications as well as publications that are being started.

Anaerobic wastewater treatment | A process devised by FlexBio Technologie GmbH in Einbeck, Germany, allows breweries to handle their wastewater sustainably and to exploit the energy it contains. The new generation of anaerobic wastewater treatment plants is compact and modular and provides small and medium-sized breweries especially with a solution that is economically viable.

Water worldwide | Euwa water treatment systems guarantee top water quality and economy worldwide. Its portfolio of services ranges from consulting to turnkey plants. Euwa attaches great importance to the development and use of its own technologies, the majority of which are protected by patent. BRAUWELT International spoke to Michael Eumann, managing director, and Wolfgang Winkler, technical director, about the developments in and future of water treatment.

Inactivation of bacterial contamination | Conventional disinfection methods are usually associated with high expenditure, risks and costs. This study describes use of diamond electrodes as a promising disinfection technology for inactivation of bacterial contamination in various water matrices.

Raising energy efficiency | In every brewery plant, there are places where valuable flash steam is blown off. This can principally be recovered in a simple and effective manner. Energy efficiency of a plant is thus significantly improved. This article describes various possibilities for utilising flash steam.