Management

Merger | Plant-engineering company Esau & Hueber, based in Schrobenhausen in Upper Bavaria, Germany, has developed significantly in recent years and has been able to open up new markets in the life sciences sector in both process engineering and fermentation technology. In August 2024, the Swiss technology group Bühler acquired the company. In this interview, Christoph Sedlaczek, Managing Director at Esau & Hueber, and Johannes Preiss, Head of Malting & Brewing at Bühler, look back on the company’s integration.

Management

Expanding the portfolio | In the following article, BRAUWELT International author Horst Dornbusch talks about the need for craft brewers worldwide to diversify their portfolios and offers some background information on the legal situation for setting up a craft distillery. This article was originally published in the July/August 2025 issue of The New Brewer and is being reprinted with permission from the Brewers Association.

Brewhouse

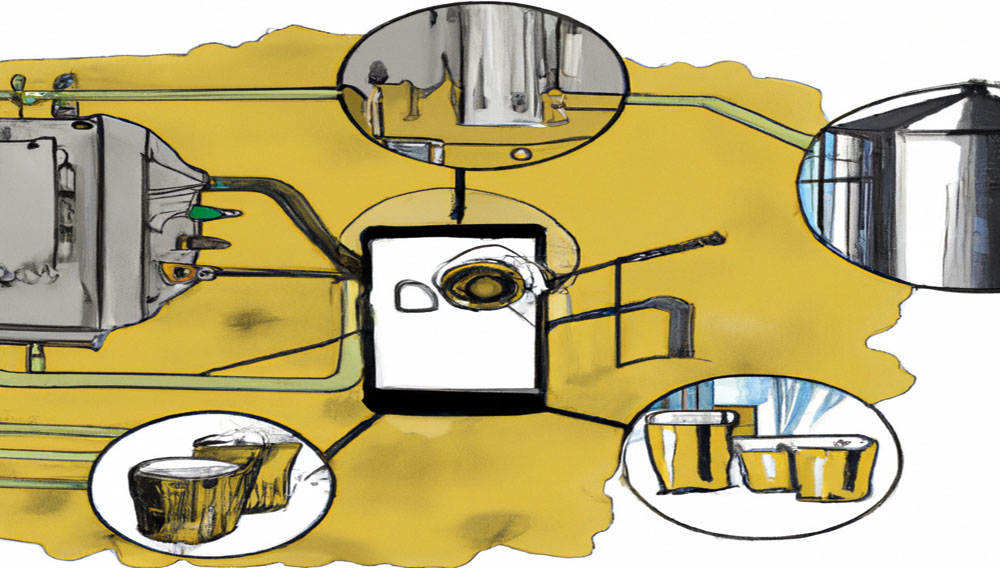

Synergistic effects and opportunities | Digital transformation is rapidly changing the brewing industry. How can breweries ensure their production is more efficient, sustainable and future proof? Following the merger with Schneider Electric, BRAUWELT International spoke to Jürgen Wölfl, Vice President Proleit Software Services, and Frederic Vanhove, Global Head of Sales at Proleit, about innovations, modularity and the synergistic effects that result from the collaboration.

Management

Identifying potentials | Efficiently and effectively recognizing relevant optimization potentials along a supply chain is one of the essential challenges of today’s supply chain management (SCM) in the brewing industry. Supply chains for beer products are generally complex, the starting points are diverse, and resources are limited. A structured SCM benchmarking of all dimensions of SCM helps to identify significant potentials quickly and accurately.

Management

Dodging downtime | Decent maintenance is an indispensable part of smooth beer production operations. Often, maintenance programs are at a disadvantage since they lack an overarching understanding of what needs to be maintained, a symptom of which are unforeseen bouts of unplanned downtime. These problems can be solved through graphic visualization and precise maintenance forecasts, which fortunately allow for considerable cost savings by reducing downtime while also alleviating both hours spent on extra work for employees and undue stress. The company Flowsight, in collaboration with the S. Riegele brewery in Augsburg, has laid the foundation for keeping maintenance under control with AI.

Management

Maintenance and expansion | KHS is intensifying its customer relations with an extensive range of measures. These include building up and further qualifying its network, standardising structures and processes as well as hiring more personnel worldwide.

Management

Contemporary technology | Artificial Intelligence (AI) is on everybody’s lips. This topic has been elevated to mass attention at the latest since the hype about ChatGPT by the OpenAI company. The so-called ChatBot is just a single albeit quite tangible application example. AI often provides many unassuming solution approaches that may assist the private and corporate daily routine. This article describes the benefits of AI in the brewing sector.

Management

A tool for the brewing industry | Digitalization is a tool which – when used wisely – will help breweries to become more flexible, efficient and sustainable. Alexander Fröhlich from automation software expert Copa-Data and Piergiovanni Stefani from the industrial software house Treesse Progetti explain how companies can profit from this investment and what to consider when starting a digitalization project.

Energy/Environment

From marketing to action | Many entities want to be climate-neutral: companies, communities, cities, entire countries. And it goes without saying that products should also be climate-neutral. But what’s behind it all, and can this goal actually be reached? In this part of the series, we examine the snags and pitfalls of climate neutrality and show what an honest approach towards the protection of our climate can actually look like.