Cleaning results validated | Spray shadow tests are a useful and proven tool for validation of automatic cleaning systems. This holds true for new installations, changes to existing systems and regular revision. Based on two industrial examples, the usefulness of two different spray shadow tests, both used at VLB, is illustrated.

Optimised cleaning | On-demand cleaning is today often seen as a vision for a new form of sanitation. But what’s behind this? How is the need for cleaning defined? Martin Löhrke, CEO of Jürgen Löhrke GmbH in Lübeck, Germany, takes a look at the options already in place to meet the requirements of individual cleaning operations.

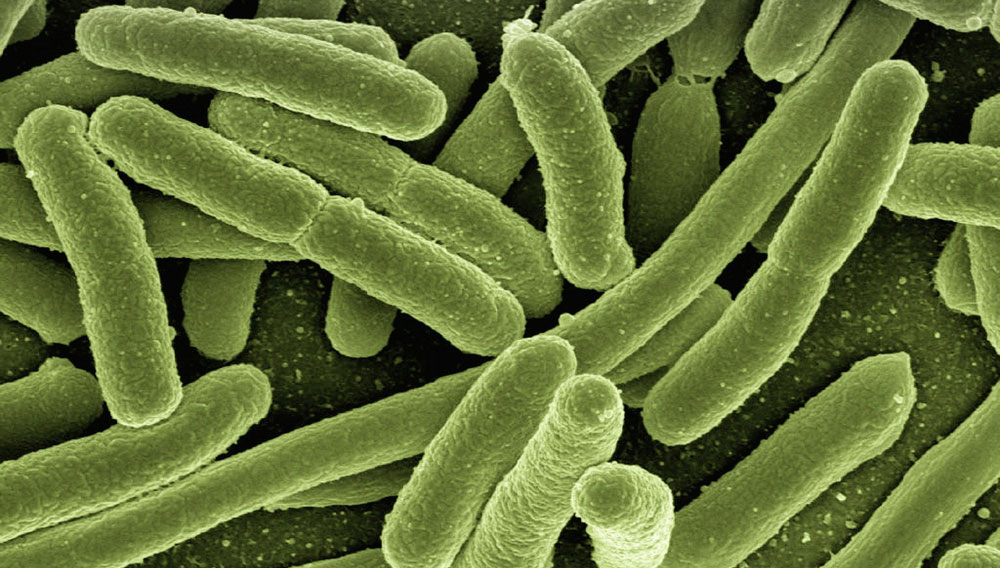

Brewery hygiene | If we look back on 50 years of brewing microbiology, we gain a number of extremely interesting insights. Can we draw a positive conclusion here or are there also negative aspects that have to be taken into account?

Recommended cleaning intervals | Beer hoses are currently being analysed in terms of life and cleanability in the context of an in-depth study at the Technical University of Munich (TUM) in Freising. Investigations described focus on appropriate cleaning intervals. Growth patterns of various microorganisms in beers were recorded in order to come up with information about necessary cleaning intervals of beverage dispensing units.

Barrel ageing | In recent years, maturation of beers in wooden barrels is becoming an interesting avenue for breweries to expand and refine their beer portfolios. Especially in the craft beer sector there is an increasing consumer demand for more complex flavours and aromas, many of which can be obtained through barrel ageing of beer. However, microbial spoilage of the barrel has to be effectively controlled in order to ensure consistent product quality and reduce profit losses.

Spent grain residue | Mash filters are currently the most common alternative to the classic lauter tun. The central filtering medium are filter cloths made of plastic. These filter cloths need to be thoroughly cleaned as following filtration they may be covered with spent grain residue.

Concentrated impurities | Modern machines for washing bottles, with their combination of chemical, thermal and mechanical cleaning functions, ensure that containers are cleaned properly. Nevertheless, the introduction of organic and inorganic impurities into the cleaning solution derived from adhesives and labels often presents special challenges. Caustic filtration and filtration of liquid in the water zone can offer more security in achieving the desired cleaning effect.

Anaerobic wastewater treatment | A process devised by FlexBio Technologie GmbH in Einbeck, Germany, allows breweries to handle their wastewater sustainably and to exploit the energy it contains. The new generation of anaerobic wastewater treatment plants is compact and modular and provides small and medium-sized breweries especially with a solution that is economically viable.

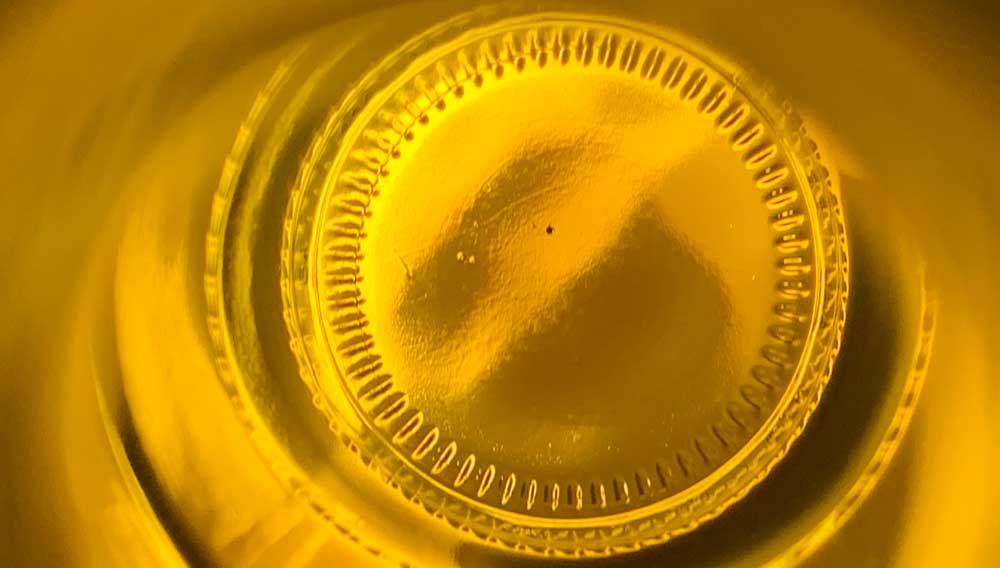

Inspection of empties | Regular verification of cleaning performance of bottle washers in breweries is important in order to ensure perfect product quality and product safety. This is the reason why the Research Center Weihenstephan for Brewing and Food Quality, Freising, Germany, in cooperation with five breweries, validated a test series with standardised contaminated bottles. This should enable breweries to carry out their own checks.

PAC bottle washers meet the highest demands for every application and requirement – whether small or large capacity, even in particularly tight spaces.

Adsorption techniques | Humidity and condensation are a recurring problem in breweries. It is indeed possible to solve this problem. Zwiefalter Klosterbräu, located in the district of Reutlingen, Germany, succeeded, together with the Cotes experts from Denmark, in achieving remarkable success in controlling the climatic condition of ambient air. Using adsorption techniques, full control of air humidity is possible.