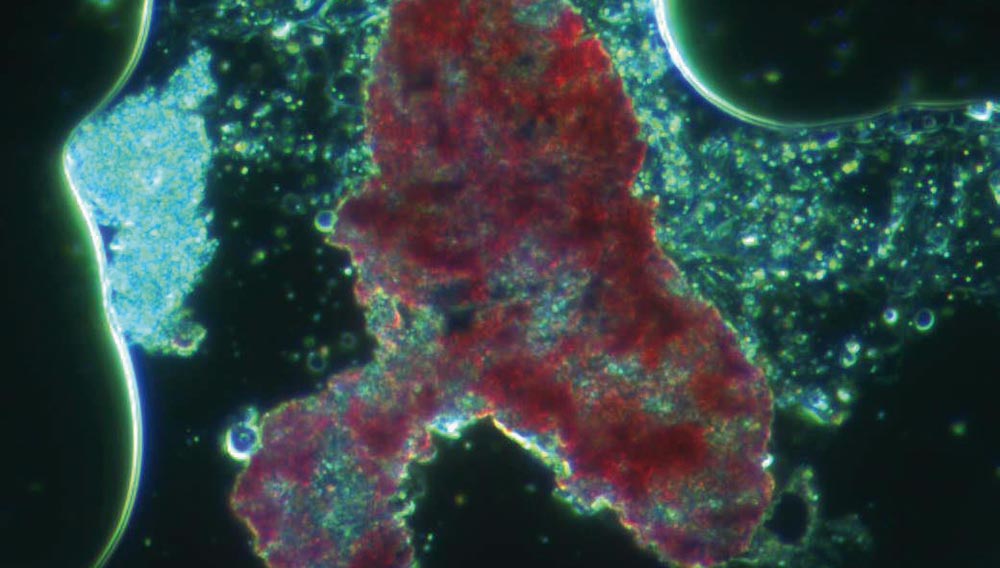

Cleaning as required | Part 1 of this article series (BRAUWELT International no. 2 2020, pp. 120-122) introduced the Condition Based Cleaning (CBC) concept for filling lines in breweries. This method is supposed to improve hygienic safety and optimise cleaning processes with the help of an online biofilm measurement, where cleaning and disinfection measures are initiated when the microbiological load reaches a predefined level. It takes the actual microbiological condition of the surfaces into account and does not operate at time-defined intervals, as usual in practice. The following second part of this article series presents first results from the field.

User-friendly | Hygienic production of food, pharmaceuticals and cosmetics requires rigorous and application-specific cleaning of the production area. The plants are frequently complex and an efficient design of the cleaning system can pose a real challenge. This article introduces an efficient software for simulation of industrial cleaning processes. Accordingly, needs-based sizing of spray cleaning systems can take place already in the design phase. The software is currently in the final test phase and will presumably be launched in the third quarter of 2020.

Optimization and costs saving | Avoiding product contamination and at the same time reducing costs are mutually exclusive at first glance. In practice, however, this can be achieved by monitoring the actual microbiological condition of the bottling machine online.

Pure drinking pleasure | When it comes to serving beverages, the process of cleaning the systems used to dispense these beverages is one of the most frequently discussed topics. This has been the case since the end of the 19th century, when the first modern dispensing systems were in operation. In addition to the general capacity for these systems to be cleaned, the focus has always been on the effort and the resulting costs. However, two aspects of a clean dispensing system have been widely ignored: consumers are protected, and the restaurateur earns money. Often forgotten are those who clean dispensing systems. They are expected to clean them thoroughly for a very low price.

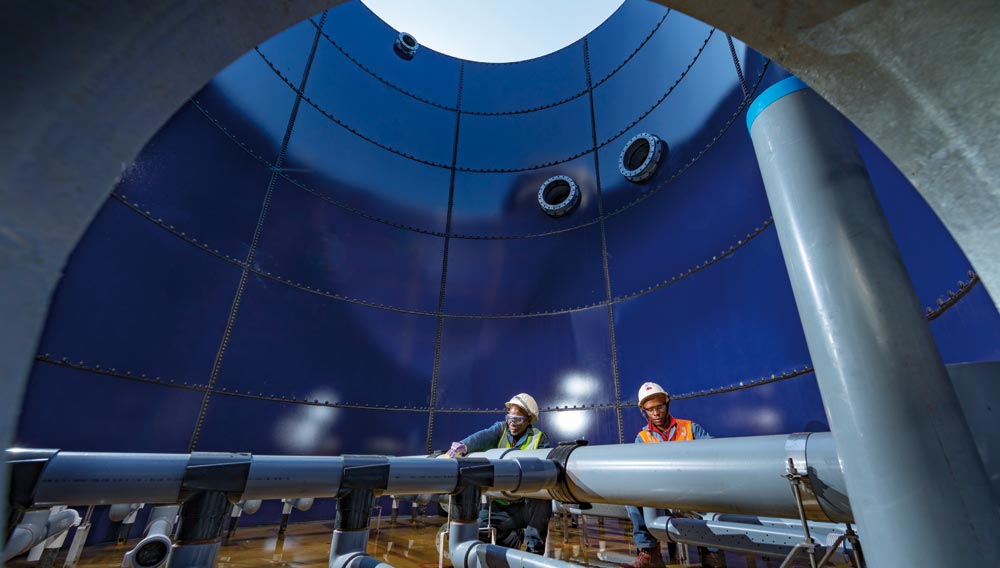

Adaptive and user-defined | New robotic cleaning technology makes a faster and safer cleaning of tanks and vessels possible with controlled, adaptive jets. The Adaptive Jet Cleaner (AJC) allows the cleaning process to be customized in ways which were not previously possible, while also tremendously boosting efficiency.

Adsorption dehumidifiers| Condensation and moisture represent daily challenges for breweries. Mold and moisture-related damage places a burden on production. In order to counter this problem, two German brewers chose to install adsorption dehumidifiers to regulate the humidity in the air inside their breweries.

Turbidity measurement | Process-compliant and hygienic turbidity measuring systems up to 13200 FAU – and soon even to 26400 FAU – are initiating a paradigm shift in many areas of food and beverage technology. Known applications such as separators and filters in breweries can now be monitored much more efficiently in terms of operation and economics.

Active ingredients and their effects | Which additives are available for bottle washers and how have they been developed? This article explores individual compounds and the purposes they serve in the cleaning process, from special additives for specific cleaning issues to the filtration of caustic. These can offer opportunities for improvement but may also be detrimental.

SME compatible | The Bavarian Karmeliten Brewery in Straubing is the first German brewery to decide on a turnkey installation of a fully biological treatment plant. The carrier-based system combining anaerobic and aerobic wastewater treatment of the Dutch company Aqana completes the energy/environmental sustainability concept of a CO2 neutral brewery that has won several awards. It has been grant-aided by the German Federal Government.

Rigorous Monitoring | Currently, an estimated 7.5 billion people live on Earth. If all of them were the size of microbes, they would all easily fit in a large cup of yogurt. Thus, a hairline crack (in tanks, piping or seals) with a length of 3 mm and a depth of 0.03 mm provides sufficient space for around 100 000 microorganisms. Sometimes visual comparisons are useful to put hygienic requirements in production in the proper perspective.

There’s a first time for everything | In breweries, quite often one hears statements like “Why do we need hygienic design? We clean everything all the time anyway. Hygienic design is the same as aseptic operations and we don’t need that.” In practice, this can have disastrous consequences. Hygienic design means that all surfaces that come into contact with the product and all external surfaces must be so fabricated that neither contamination nor soiling can readily endure on them. Every surface must also be able to be cleaned easily.