Single rest | Interest in reduced-alcohol and alcohol-free beers is growing. Can they also be produced by craft brewers? The authors describe a simple, isothermal mashing process in which temperature is maintained constant at 72 °C for 120 minutes. Using different malt mixes, original gravities will range from 10.6 to 12.1 °P. The alcohol content of the finished beer is between 1.9 and 3.5 per cent ABV and, when adding Saccharomycodes ludwigii, about 1 per cent ABV.

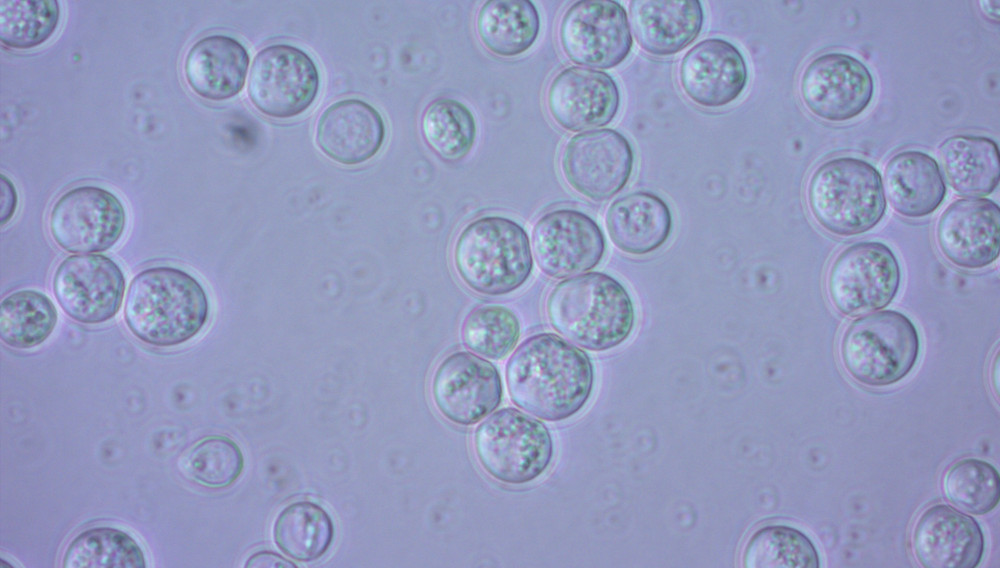

Brief overview | “Yeast is only human after all” – that’s how it should be treated by brewers. In the context of a thesis at the University of Applied Sciences Weihenstephan-Triesdorf in Weihenstephan, it was found that yeast management in breweries is not always given adequate attention though yeast quality has such a significant influence on beer quality. This contribution provides a brief overview of the most important aspects of yeast management.

Quality assurance | Dry hopping has become an essential technique in beer brewing, designed to create the aroma of a beer and to produce pronounced, typical beer styles. This excerpt from an extensive research project provides some insight into the chemical-physical changes associated with dry hopping.

Exhaust heat project | An innovative concept that uses fermentation and refrigeration compressor energy via heat pumps has been introduced in the Puntigam district of Graz in Austria. The modern heating system for a new residential estate of 800 flats is the result of a cooperation between Brauerei Puntigam, Kelag Energie & Wärme GmbH and C&P Immobilien AG.

A renaissance | Old-fashioned, outdated, yesterday’s news? Not in the least. For anyone involved with beer, “open fermentation” is unescapable. It is the original method of beer production. For quite some time now, open fermentation has been supplanted by other methods in breweries for practical and economic reasons, and yet it has never been forgotten.

Energy savings | From today’s perspective, some of the individual stages in the beer production process are extremely energy intensive. Lots of breweries thus aim to save energy by integrating innovative technologies and concepts without having to suffer any loss of quality. Pulsed electric field technology provides a number of different approaches here.

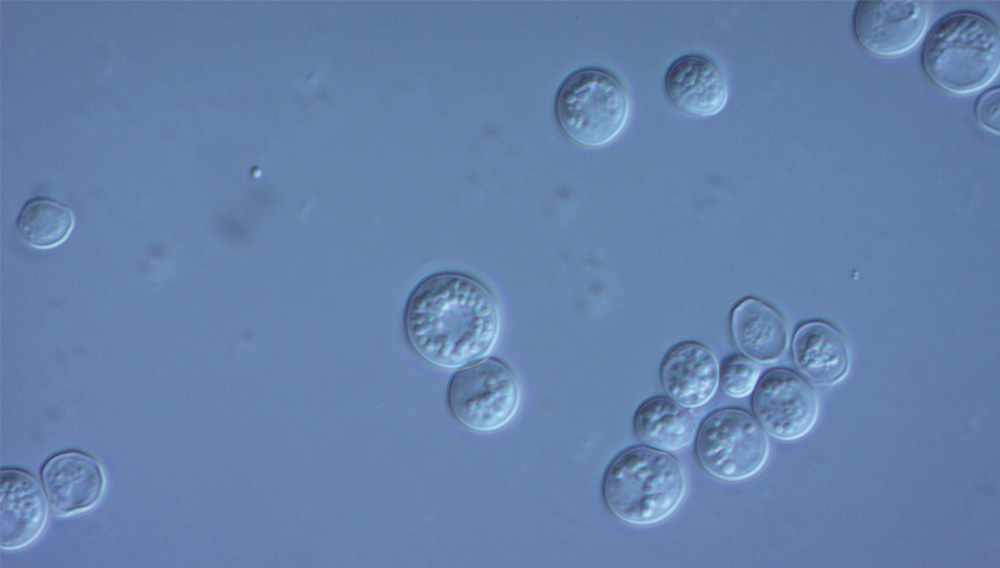

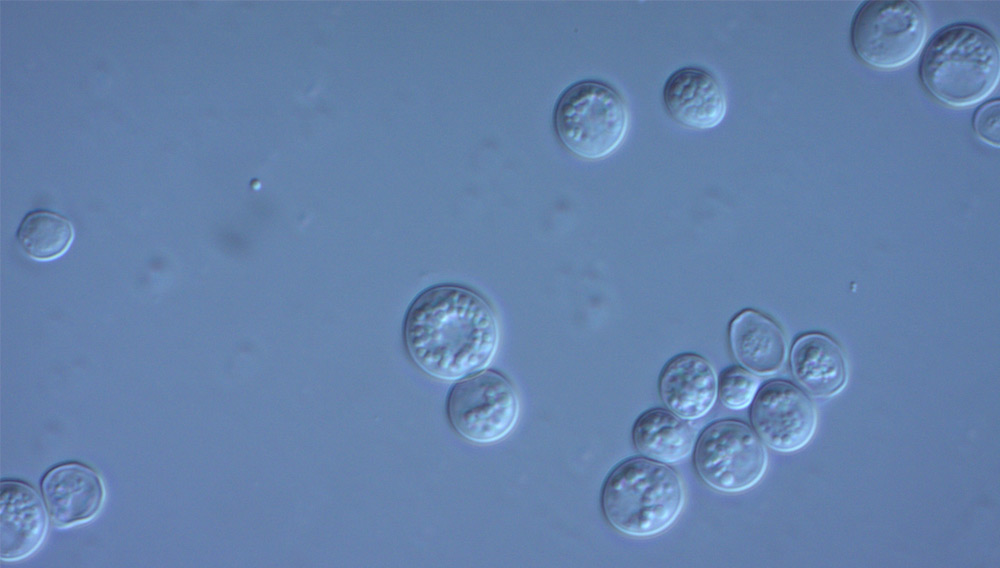

Opening up a new world | Renaissance BioScience Corp., a leading global bioengineering company based in Vancouver, Canada, has developed an innovative approach to creating novel non-GMO lager yeast strains that are immediately suitable for lager beer production, and which will help broaden the diversity of commercial lager beer strains for both major global beer producers and smaller craft breweries.

Sensory research | Branched chain fatty acids (isobutyric acid, isovaleric acid, and 2-methylbutyric acid) are major metabolites that originate from various metabolic pathways. Thus, these compounds are contained in various foods and beverages. These compounds in beer have their origins in malts, hops, and also from yeast metabolism. It is well accepted that these fatty acids may give rise to some rancid off-flavours. However, an effect of these compounds on overall beer flavour has not yet been fully elucidated. The following article summarises a part of the research results which have already been published in BrewingScience, 2019, issue 6: November/December.

Well-balanced | On 16 March 2021, AB Vickers, part of the Lallemand Brewing Business Unit and a global leader in the field of brewing process aids, released its new yeast nutrient solution YeastLife O™.

Enzyme activity | Under the German Purity Law 40 different types of malt, over 200 strains of yeast, more than 250 hop varieties and the way in which the brewing process is performed alone provide many ways of developing styles of beer [1]. Besides water and malt, yeast and hops are the key factors in determining the flavour and aroma of a beer. Research has shown that not only do the quantity and timing of the hop dosage play an important role here but also the biochemical interaction with the strain of yeast used.

Testing the rule of thumb | The average beer drinker is still usually not familiar with the concept of original gravity or original extract. It is a common rule of thumb though that the ratio of 2½ (original extract, OE divided by the alcohol, as ABV) would be “about right” in most bottled beers. The authors have decided to find out in what way the rule of thumb factor of 2½ holds true and have, during the course of this investigation, discovered links to attenuation and inferred drinkability especially in lager type beers. These concepts were also checked against the portfolio of beers produced by Schilling Beer Co., a craft brewery situated in the northern part of New Hampshire, USA.