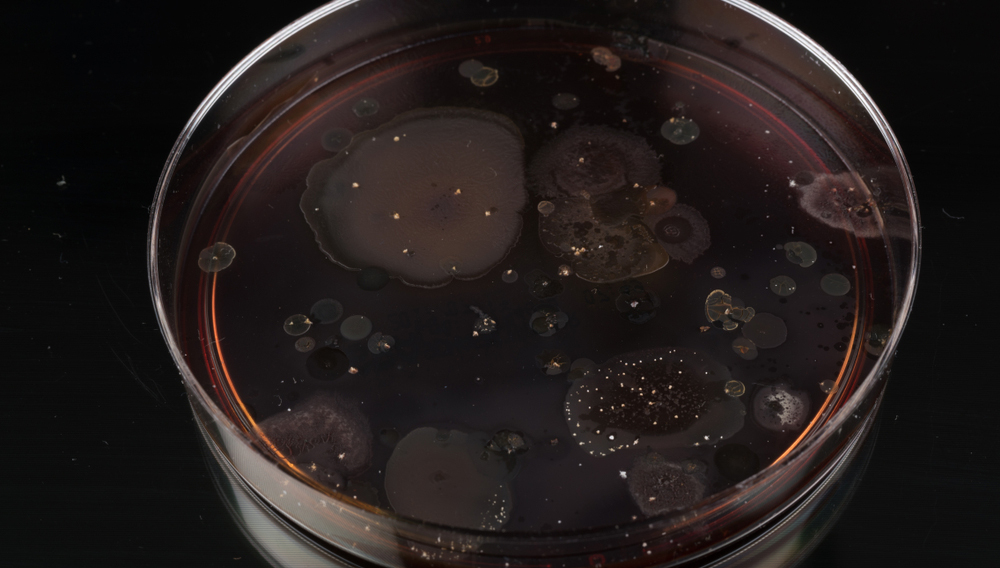

Rapid and reliable | Detecting yeasts that are detrimental to beverages is essential when ensuring the microbiological quality of the brewing process and finished products. In the current study, the growth characteristics of all important types of spoilage yeast were comprehensively analyzed under selective and non-selective enrichment conditions. The optimal duration of pre-enrichment for sensitive detection by real-time PCR as well as factors interfering with spoilage yeast growth could be determined.

Adsorption dehumidifiers| Condensation and moisture represent daily challenges for breweries. Mold and moisture-related damage places a burden on production. In order to counter this problem, two German brewers chose to install adsorption dehumidifiers to regulate the humidity in the air inside their breweries.

Unique Character | The craft beer movement has inspired craft brewers all over the world to experiment and play with new approaches to beer production. Among these approaches is barrel aging, which has risen in importance and now is considered part of the standard practice in the industry. Barrel aging provides a means for producing unique character in beer, rooted in the distinctive aromas and flavors formed over time using this method. However, to make this type of beer, the brewer must possess a certain amount of knowledge on how pre-treated or previously occupied barrels can change the aroma and texture of beer. This article explains the factors at play during barrel aging and the technical aspects of aging beer on wood to modify and generate desirable aromas and flavors.

Turbidity measurement | Process-compliant and hygienic turbidity measuring systems up to 13200 FAU – and soon even to 26400 FAU – are initiating a paradigm shift in many areas of food and beverage technology. Known applications such as separators and filters in breweries can now be monitored much more efficiently in terms of operation and economics.

Improved process control | Real-time measurement of process parameters is indispensable for achieving high process efficiency. Diacetyl, an indicator substance for assessment of fermentation processes and thus the point in time for cooling and hosing in the brewing process, is accorded particular commercial importance. This article provides an overview of existing measurement procedures and the potential for further development.

Optimising evidence | Detection of beer-spoilage bacteria in the brewing process is of the utmost importance. These bacteria can cause, among other things, hazes, acid and off-flavours in the product. It is extremely difficult, especially in pure culture yeast and also in cropped yeast, to track down these beer spoilers because their growth is suppressed by yeast. In addition, these bacteria are often present as trace contaminants in such yeast. In this study, a method has been developed to detect beer-spoilage bacteria in pure culture yeast much faster and with a higher degree of reliability than has been the case with existing methods.

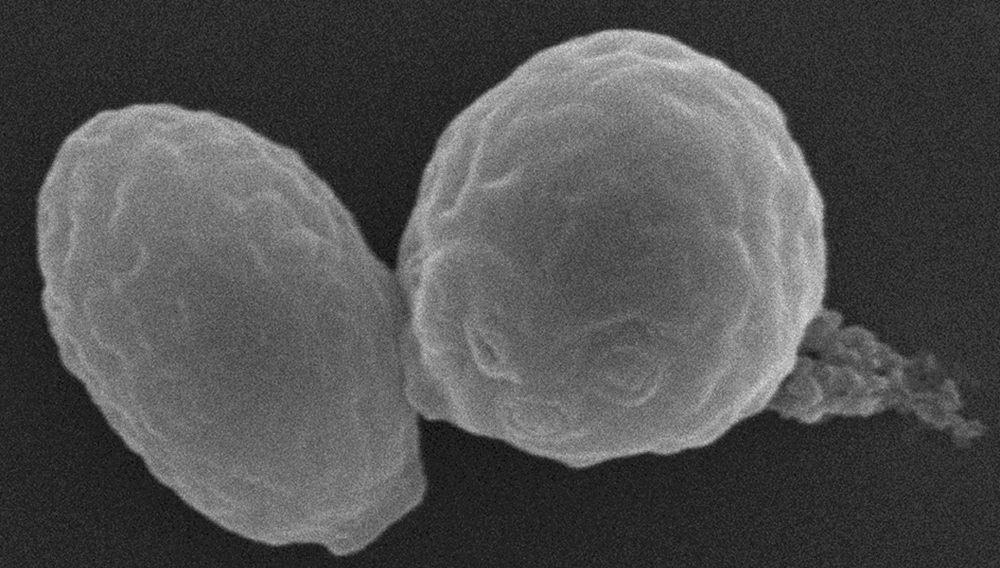

Yeast recycling | The physiological state of the yeast cell has a major influence on fermentation behaviour. In breweries, yeast is usually harvested at the end of fermentation and re-used for the next brewing cycle. It is important to assure optimal yeast physiology, in particular good yeast vitality, in order to use the yeast culture several times. The number of cycles is based on the experience of the brewmaster.

Inert gas from own production | Nitrogen is used in many areas of the food industry. The gas is also being increasingly used in breweries to prevent the spoilage of beer and to keep it fresh for a prolonged period. The Bavarian company BrauKon, as a brewing equipment manufacturer and brewery, has gained intensive experience with the use of nitrogen and is familiar with the areas in which nitrogen offers breweries advantages over the use of carbon dioxide.

White Labs | As of September 1, all yeast produced by White Labs Copenhagen is 100% certified organic yeast.

Scientific Articles | After the first BrewingScience Yeast Special in April 2019, the BrewingScience editorial team is looking forward to your submission for the second Yeast Special that will be published on 24 April 2020. The submission phase is now open!

Genetic test | Some contaminant yeasts make beer bottles and cans explode. Apart from being dangerous for consumers these ‘diastatic’ yeasts also cause loss of beer batches due to off-flavours, increased alcohol and over-carbonation in products. VTT scientists developed a genetic test for brewers to detect the strains that cause these problems.