Enzymes | In November 2020, Kerry, the international Taste & Nutrition company from Ireland, released a technical report detailing the results of a sustainability life cycle assessment (LCA) conducted on Kerry’s range of brewing ingredients and enzymes (a study already mentioned in BRAUWELT International no. 5, 2020, pp. 348-351).

Hard Seltzer | Omega Yeast®, known for custom propped liquid yeast pitches, announces the November release of Propper Seltzer™, a yeast nutrient for non-malt, sugar-based fermentation. Propper Seltzer nutrient is compatible with any strain of yeast including beer yeast, champagne yeast, wine yeast and distillers yeast, and was designed to make things easier for brewers looking to create their own hard seltzer.

Fermentation cellar extension | Exceptional beers require extraordinary design. Retrofitting new outdoor tanks and process technology at the Jopen Brewery near Amsterdam has created new opportunities for further developments in beer production while simultaneously increasing process reliability.

Yeast research in focus | Please note: in the April 2021 issue of BrewingScience, we will focus on yeast once again. The 3rd BrewingScience Yeast Special will be published on April 30, 2021. All researchers working in the field of brewing yeast research are invited to submit their scientific articles by Monday, 11 January 2021, at the latest.

Dealcoholization | In August of 2019, “Ghost Ship 0.5 %”, a pale ale with strong citrus notes brewed by the British brewery Adnams in Southwold, UK, sailed back to the island nation with the gold medal it earned at the World Beer Awards. The award rounded off a year of meticulous product development with the new GEA AromaPlus dealcoholization system.

Kokumi-activity | Insight into the biochemical forces governing beer maturation has been lent further support by the “kokumi-active” conjecture. A further objective was to innovate a more time-efficient maturation process which replicated the flavour-enriched outcome of traditional lagering. The proposal is that pressure fermentation may lead to such a solution.

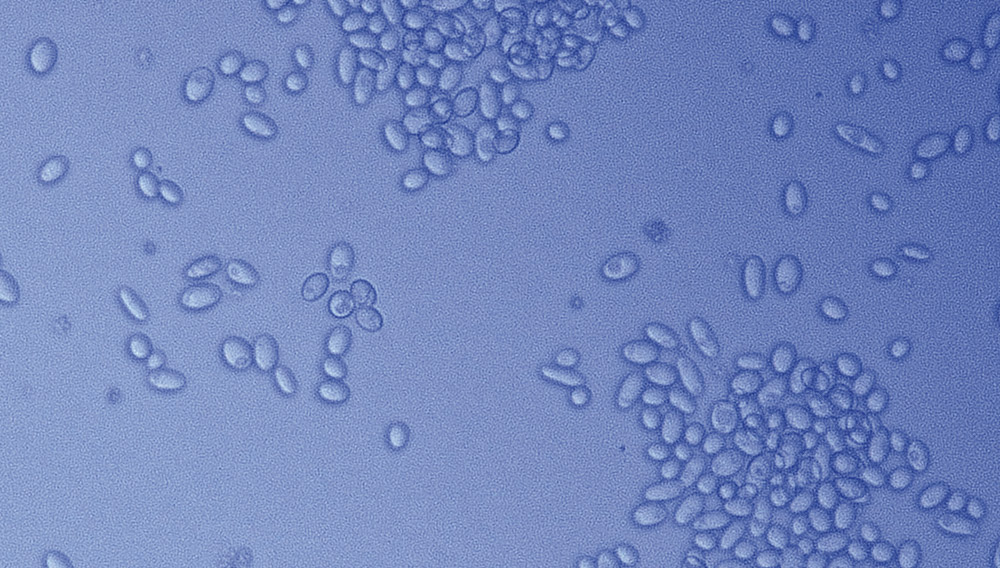

Over-attenuating yeast | At the turn of the century, hardly anyone in Germany was familiar with this yeast. Nowadays, Saccharomyces diastaticus has virtually become a household name, especially among craft brewers. Some use it to brew novel beers in the style of those from Belgium. Others, however, fear this yeast and despise it as a beer spoiler, conducting extensive analyses to detect the merest traces of its presence in an effort to eradicate it in their breweries.

Traditions and opportunities | There are many different ways for producing sour beer, ranging from modern kettle souring to traditional long term mixed fermentation. This article describes the most important souring methods, emphasizing opportunities to diversify the portfolio of sour beer styles.

Lallemand | Expanding even further the “We Brew With You™” concept, LalBrew® Verdant IPA yeast is the result of a collaboration between Lallemand Brewing and Verdant Brewing Co, a craft brewery focusing on IPAs and modern hop-forward styles.

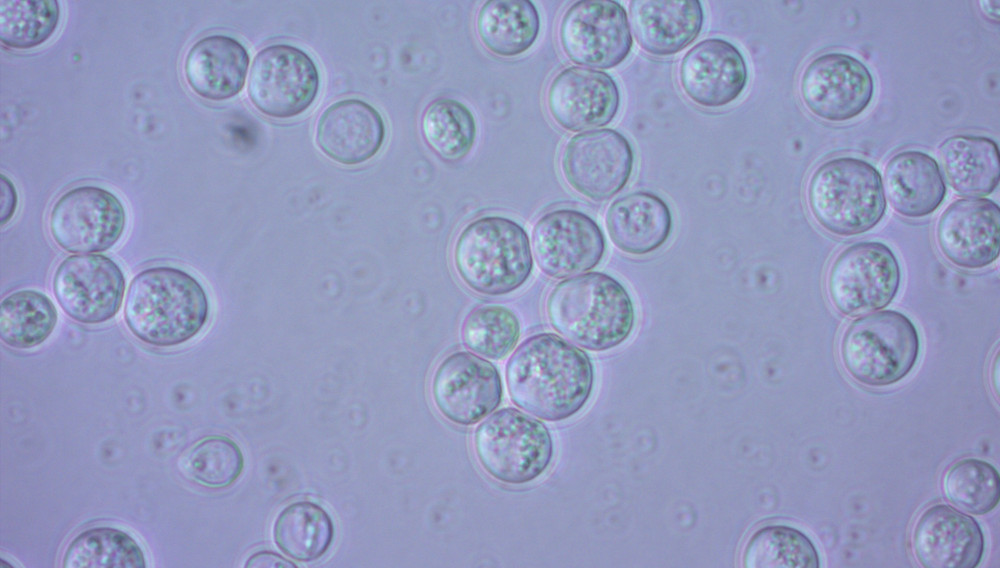

Balanced aroma profile | At over 90 percent, bottom-fermented beers dominate the global beer market. The bottom-fermenting yeast S. pastorianus behind this success has become a pillar of the brewing industry [1]. A number of popular and widespread strains used in the production of bottom-fermented beers have been extensively characterized, e.g. the most commonly used strain S. pastorianus Frisinga – TUM 34/70®. However, we know very little, if anything at all, about rarely used bottom-fermenting yeast strains out of the past. It has been rumored that beer fermented with the historical TUM 35 strain exhibits an extremely mild, balanced aroma profile with a high degree of attenuation. Although long-standing culture collections exist, TUM 35 was not deposited anywhere and thus was considered lost. So, how was the resurrection of this strain possible?

Kokumi-active compounds | The biochemistry of prolonged beer maturation is poorly understood. This knowledge shortfall has constrained our utilisation of it to help maximise beer flavour quality, minimise operational costs, and promote innovation. A science-underpinned model based on yeast cell excretion and incorporating flavour-modulating tripeptides is proposed in this article. It promises a step-change in our understanding of maturation and the potential to innovate.