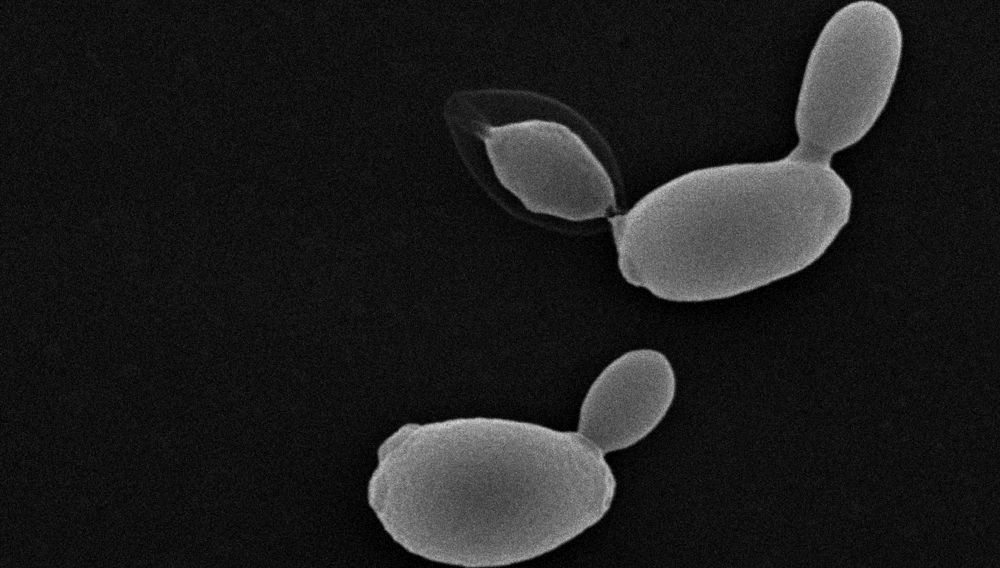

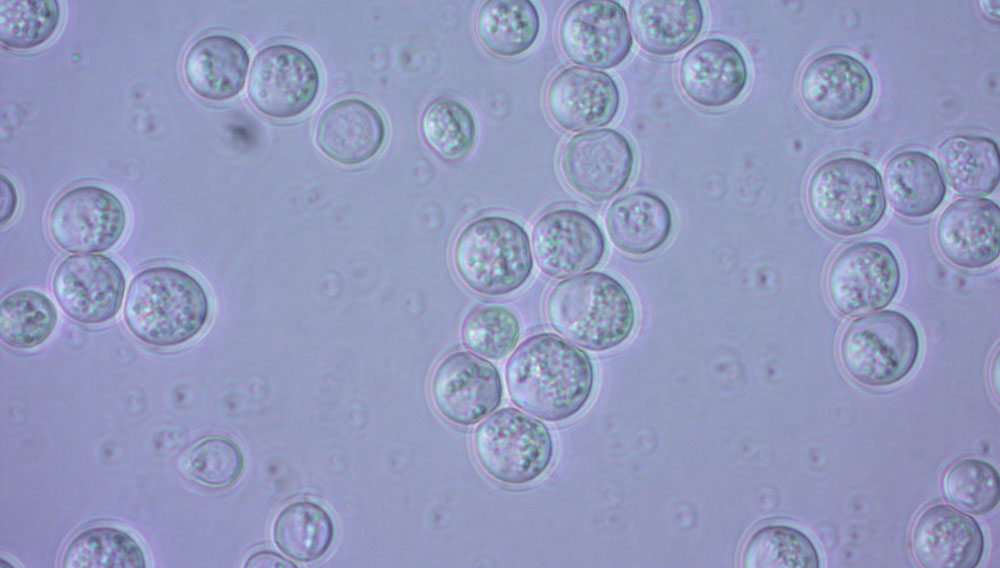

Advances in biotechnology | Yeast cells, Saccharomyces yeasts among others, are essential in biotechnological research. However, research is nowadays also directed to the question how the age of a cell has an influence on its function. Using up-to-date techniques, yeast cells can be sorted according to age. This innovative method reveals fascinating insights into age-related changes in yeast metabolism and gene activity of yeasts.

The offspring wins | This is the third of a four-part article series about the historical evolution of our understanding of the nature and function of yeast in fermentation. It investigates the improbable conditions that made the unlikely hybridization of S. cerevisiae and S. eubayanus in late-Renaissance in Bavaria, as well as its subsequent survival, possible.

Troubleshooting | Fermentation upsets are reported increasingly frequently, e.g. primary fermentation becomes stuck, secondary fermentation does not proceed properly, yeast flocculates or remains in suspension. When trying to pinpoint the causes, the following statement is very frequently heard: “We did not change anything at all, but extract degradation is incomplete, we have diacetyl in the product” etc. So what’s causing these upsets?

Yeast propagation | The thousand-year-old art of brewing is undergoing a significant transformation in our modern day and age thanks to scientific advance and technological development. The term ‘breath of beer’ refers to the volatile or fugitive gaseous components (VOCs) that are produced during beer fermentation. These volatile components, especially ethanol, can be measured to better understand and monitor the complex process of brewing.

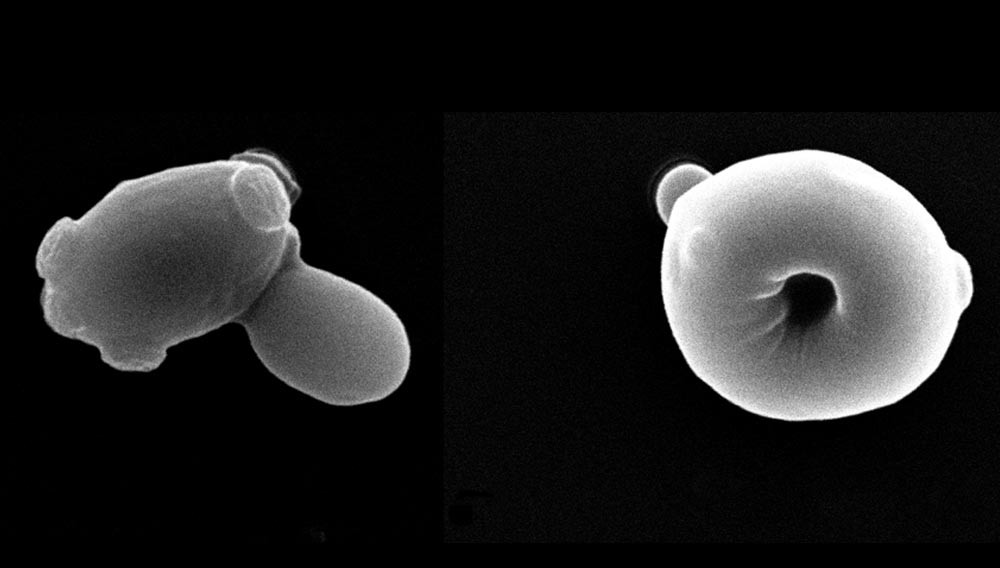

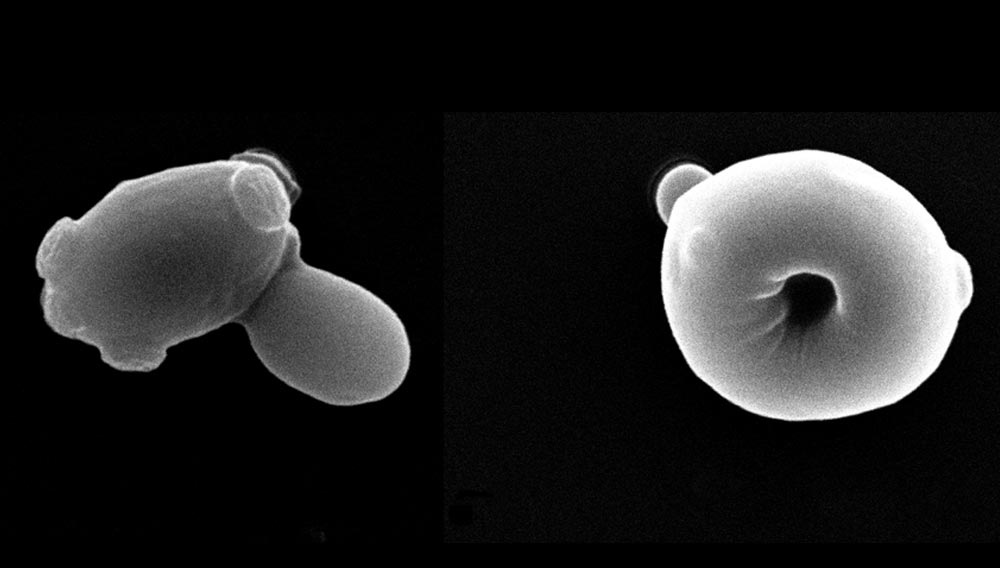

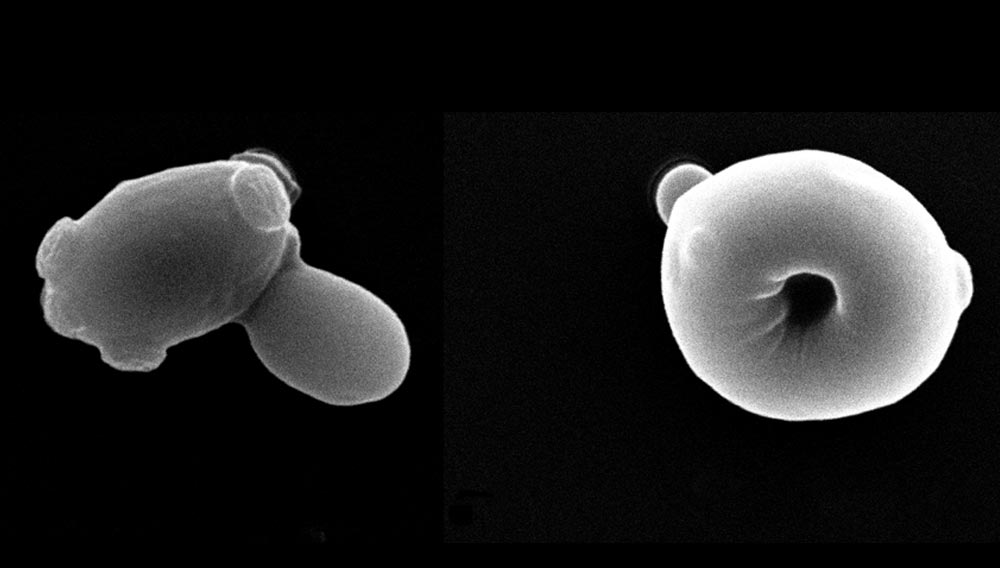

When Eubayanus met cerevisiae | This is the second part of a series about our understanding throughout history of the nature and function of yeast in fermentation. The first part (BRAUWELT International 5, 2024) dealt with the puzzling discovery of two side-by-side fermentations, “cold” and “warm”, in the small town of Nabburg, in Bavaria’s Upper Palatinate region, in 1483. It also dealt with the 2011 discovery of the wild S. eubayanus yeast in the high Andes in Argentina. A subsequent genome sequencing proved that this wild yeast was the missing second parent of S. cerevisiae. The current installment examines a few theories, some speculative, about how this South American yeast or its spores might have reached Bavaria – a question that is still not resolved, and subject of vigorous investigations.

Microbial discovery | The year was 2011 and the location was a patch of frigid forest, high up in the Andes, in Patagonia, along the border between Argentina and Chile, at the intersection of latitude 41 °S and longitude 71 °W. There, five researchers under the leadership of Diego Libkind, an Argentinian microbiologist, were on an unusual mission: to find new wild yeast species in hopes that one of them would turn out to be the as-yet-unknown ancestor of S. pastorianus, our lager yeast.

Comparison of methods | Knowledge about the physiological state of a brewery’s yeast cells is essential for the brewery. A main focus is on their viability, i.e. the ratio between live and dead yeast cells as this has a major influence on the brewing process. The authors conducted a study and compared various techniques to measure viability of yeast cells.

Enzymatic sugar analysis | Accurate determination of the end of fermentation is a crucial step in controlling the brewing process. One of the main issues here is accurately assessing when fermentation ends. The secondary fermentation phase, with precise adjustment of the carbonation in the final fermented beer, must also be closely monitored [1].

Presentation of methods | Vitality of yeast is a major issue for every brewer. This applies to both yeasts propagated from professional yeast management as well as to fresh rehydrated dry yeasts. Modern brewers can choose between several methods for determining vitality of their yeast cells. One of these methods is the Acidification Power Test which can be carried out quickly and cost-effectively.

Curtailing the brewing process | Over the decades and centuries of the many advances in brewing technology, there have only been two primary objectives for any of the countless inventors, technicians and brewers: To improve quality and/or reduce costs. In the 18th installment of the Giants of Brewing History, Günther Thömmes introduces readers to a man whose work was characterized by significantly reducing the duration of the beer production process – in other words, he cut costs without sacrificing quality: Dr. Leopold Nathan.

Underestimated potential | Up until the end of the 19th century, the variety of microorganisms used as starter cultures to make beer was enormous. Their number is now totally inestimable. It was thus important to introduce pure yeast cultures to keep products clean and stable; this also meant, however, that the formerly broad spectrum of yeasts was narrowed down to comparatively few strains. This article, based on a talk given at the 11th Yeast and Microbiology Seminar 2024 in Weihenstephan, Germany, shows just what yeast can do given the chance.