Practical findings | Beer loss has always been one of the biggest challenges to breweries with regard to efficient beer production and maximisation of the beer sold. Especially when making hoppy craft beers, where dry hopping is often practiced, the beer yield is drastically reduced. Thanks to the latest practical findings from a long-term BrauKon trial, the amount of beer loss can now be significantly reduced by adjusting two characteristics in the cylindroconical vessel: essential here are a special surface finish and a defined cone angle.

Award ceremony | Dr Carsten Zufall, Cerveceria Polar, Venezuela, is the winner of the Ludwig-Narziß Prize for Brewing Science 2022. On the occasion of the 15th Trends in Brewing in Ghent at the beginning of April 2023, the research prize for the most practice-relevant publication of 2022 in the scientific magazine BrewingScience was awarded by Editor-in-Chief Dr Lydia Junkersfeld.

Vibrating sieve | Beck’s – the name is legend and the advertising campaign featuring the Alexander von Humboldt barque with its green sails cutting through the waves to “Sail away” familiar to many of us since 40 years. GEA project engineer Clemens Fries claims that this is “an inspiring environment in which to perform ‘minor open-heart surgery’.” Fries is namely responsible for the new special yeast sifting plant that’s now been integrated in Bremen as a fully-automatic process line.

Trained senses | Is a sensory panel suitable as an “analysis instrument” for monitoring the quality of spirits? Can training a panel specifically for detecting wood-derived substances, key aroma substances, color and faults common in whiskey supplement, or even replace, laboratory analysis for measuring individual substances? Are there limits, and if so, what are they? This is the third installment in the series, which began with the basics of barrel aging in part 1 and continued with the laboratory analysis of barrel-aged spirits in part 2 [1, 2]. In this installment, the authors will consider another measuring device: human beings.

Dry hopping system | In this final third part of the series of articles, the significance of the results from the second part for plant and process engineering in an industrial environment is highlighted and the advantages provided by such systems are presented based on sample projects already installed. Results are discussed and summarised at the end.

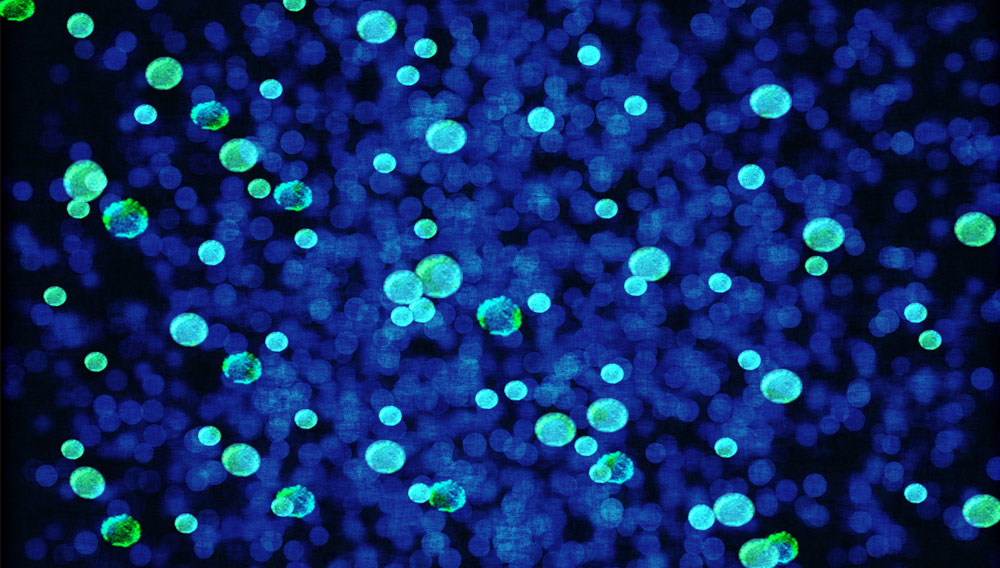

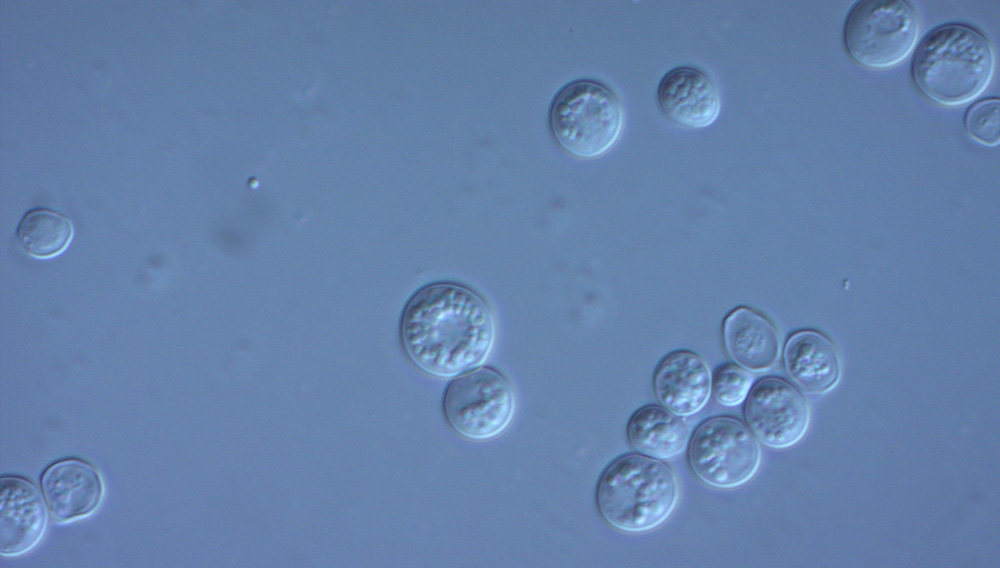

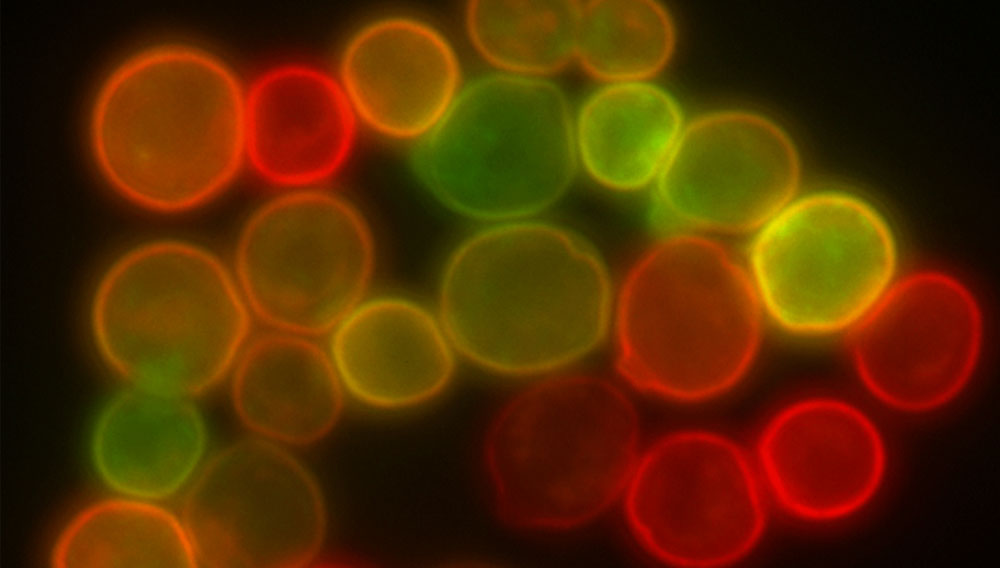

New yeast strain | LalBrew NovaLager™ is a true bottom fermenting Saccharomyces pastorianus hybrid from a novel lineage that has been selected to produce clean lager beers with distinct flavor characteristics and superior fermentation performance. This robust lager yeast strain with ideal brewing properties, including fast fermentations and high attenuation, has recently become commercially available.

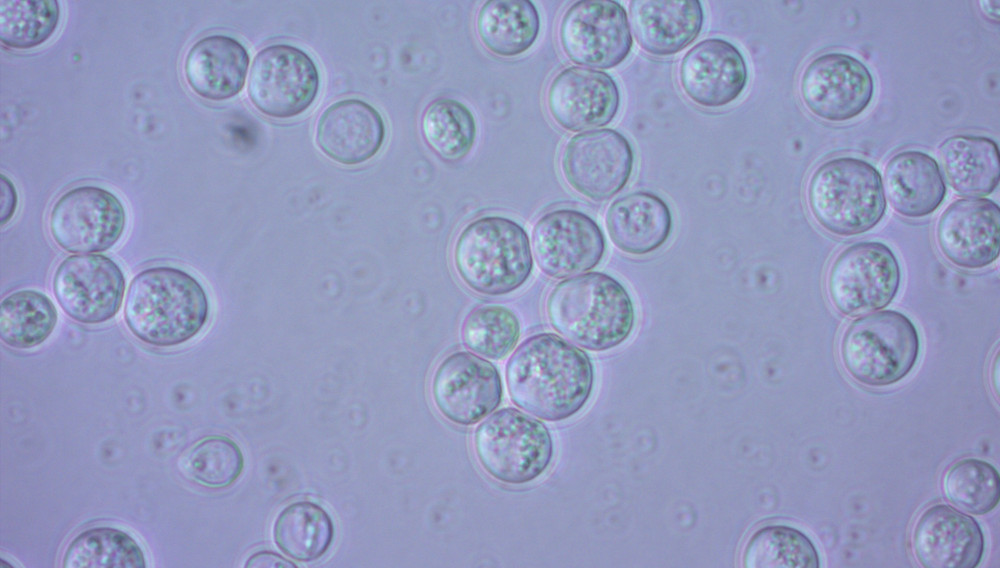

Sterile pitching yeast | Yeast quality exerts a huge influence on beer quality. A flawless and uncomplicated fermentation can only be ensured if wort is pitched with vital yeast. However, this is easier said than done – in reality, yeast management and propagation require significant investments in both time and money. Furthermore, this essential aspect of brewing does not always receive the attention it deserves. A new product from the Yeast Center at the Research Center Weihenstephan for Brewing and Food Quality not only lessens the workload but also guarantees microbiological safety.

Aroma extraction | Dry hopping poses challenges for brewers all over the world. These range from high beer losses, significant effluent pollution, low extraction efficiency to the hop creep effect. This three-part series of articles highlights the main concerns and provides an approach for finding a solution. The approach presented ranged from lab tests with just a few litres up until first industrial projects with batch sizes of more than 3500 kg of hops.

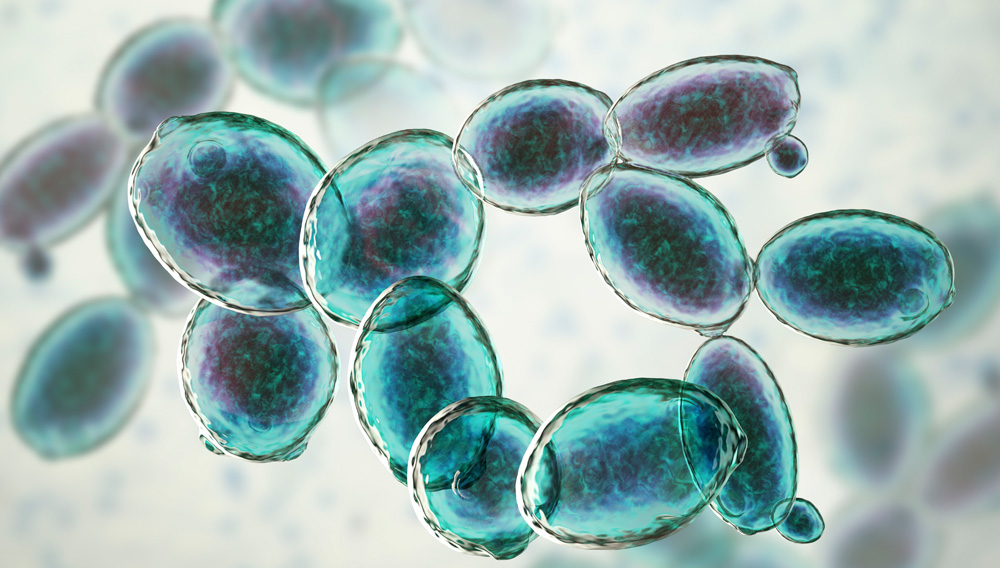

Molecular basis | Flocculation is an important facet of yeast behavior which is widely exploited in the brewing industry as an effective, low cost and natural mechanism for yeast removal from beer. This review aims to briefly summarize the current understanding of the underlying molecular biology involved in flocculation, as a condensed version of the review article “Molecular Basis and Regulation of Flocculation in Saccharomyces cerevisiae and Saccharomyces pastorianus – a Review” originally published in BrewingScience, 74 (March/April 2021).

High seas and world records | The first installment in this series (BRAUWELT International no. 1, 2022, pp. 30–34) followed the trail from the creation of the wooden beer keg to its role in the Hanseatic League and in sea voyages during the Age of Exploration. The second installment (BRAUWELT International no. 2, 2022, pp. 135–137) was devoted to recounting the struggle seafarers faced against the disease scurvy. In this final installment, Dr. Markus Fohr discusses the beer produced on modern cruise ships and how the wooden barrel has found its way into our language and even into world records.

Manuka beer | The first installation in this three-part series (refer to BRAUWELT International no. 1, 2022, pp. 30–34) described the origins of wooden beer barrels in antiquity, their use by the Hanseatic League and on sea voyages during the Age of Exploration. Those who sailed the Seven Seas were often confronted with an uninvited guest: scurvy, an insidious disease caused by vitamin deficiency. Part 2 in this series is devoted to the topic of how sailors fought scurvy and the crucial role played by spruce beer in doing so ...