Fermentation/Maturation

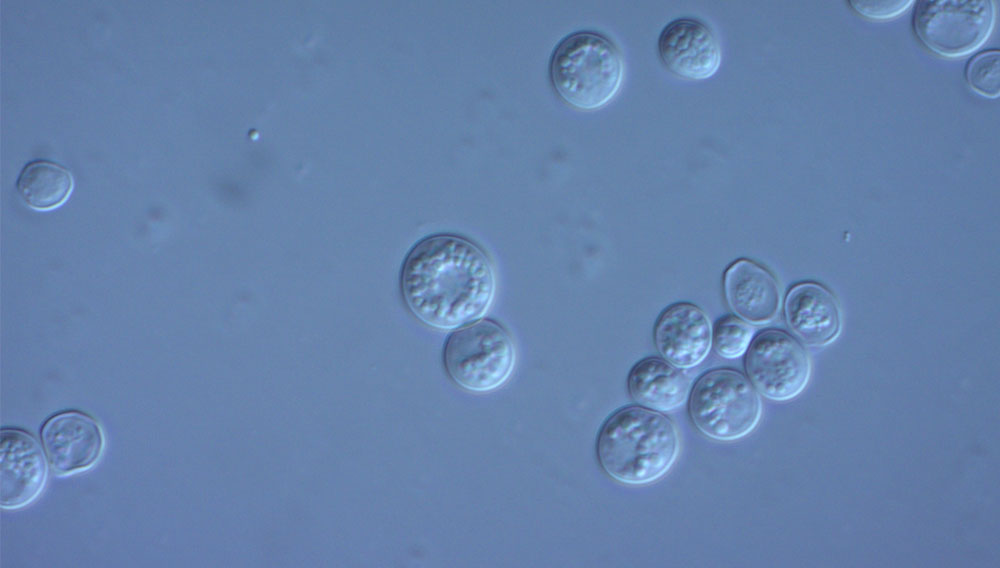

Resurrected yeast | According to Hutzler et al., in 1952 and 1953, environmental conditions and variable barley characteristics led to unsustainable brewing practices with a formerly popular Frohberg-type Saccharomyces pastorianus yeast [1]. Now identified as TUM 35, the once-extinct yeast was resurrected and made commercially available in 2019. In November of 2019, Schilling Beer Company of Littleton New Hampshire, USA, imported TUM 35 from Forschungszentrum Weihenstephan with a keen interest in the history of the yeast.

Fermentation/Maturation

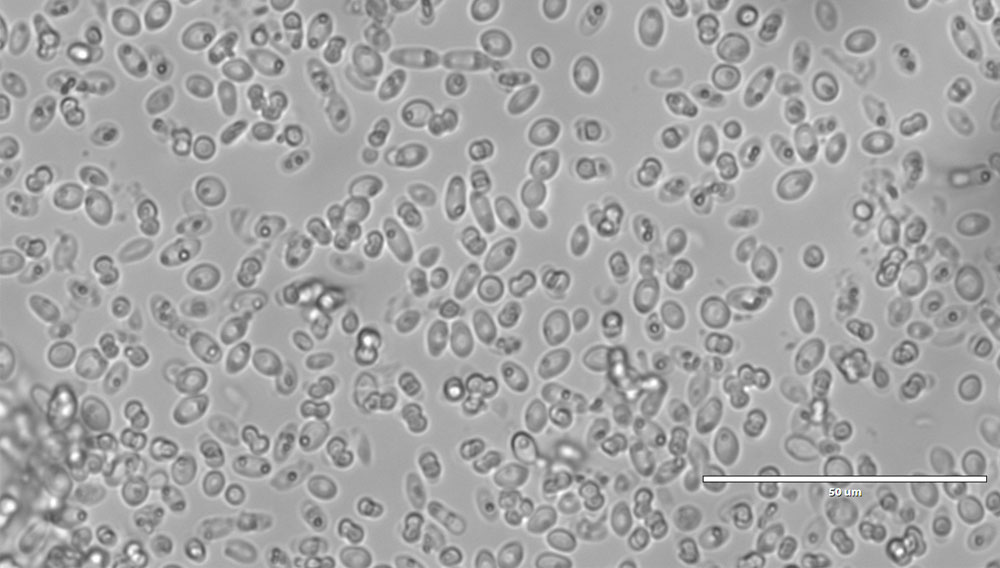

Low fermentation power | Non-alcoholic beers continue to enjoy great and increasing popularity among consumers. One production method employs low fermentation yeasts. The Spanish brewery Cervezas Gran Vía S.L. in Seville investigated the fermentation behavior of such a yeast – Pichia kluyveri – on an industrial scale.

Fermentation/Maturation

Crystal clear | Colloidal stability of beer is a key attribute, and its control is of high importance, since beer may start off clear, but it contains all the precursors that can lead to haze formation during the shelf life.

Fermentation/Maturation

Key aroma compounds | Non-alcoholic beers continue to be very popular with consumers in Germany. A variety of methods are available for their production. Each method has inherent advantages and disadvantages with regard to the aroma profile of the resultant beers. As part of a diploma thesis, an approach for producing non-alcoholic Bavarian Weissbier using maltose-negative yeast strains was investigated at the Weihenstephan Research Center for Brewing and Food Quality at the Technical University of Munich.

Fermentation/Maturation

New barrel flavors | The Infusion Spiral® provides solutions for brewers in a variety of ways: Made from staves of wood in a unique cutting process and toasted if desired, it brings new barrel flavors but can also simply provide more body and balance, especially for nonalcoholic beers, while saving storage space, energy, time, and costs.

Fermentation/Maturation

Unique experience | More often than not, breweries are now viewed as places for customers to have a unique culinary experience, one to be savored and enjoyed. For brewers around the world, this serves as strong motivation to showcase their production processes for their consumers. For this reason, some have devoted their efforts to rethinking the concept of open fermentation.

Fermentation/Maturation

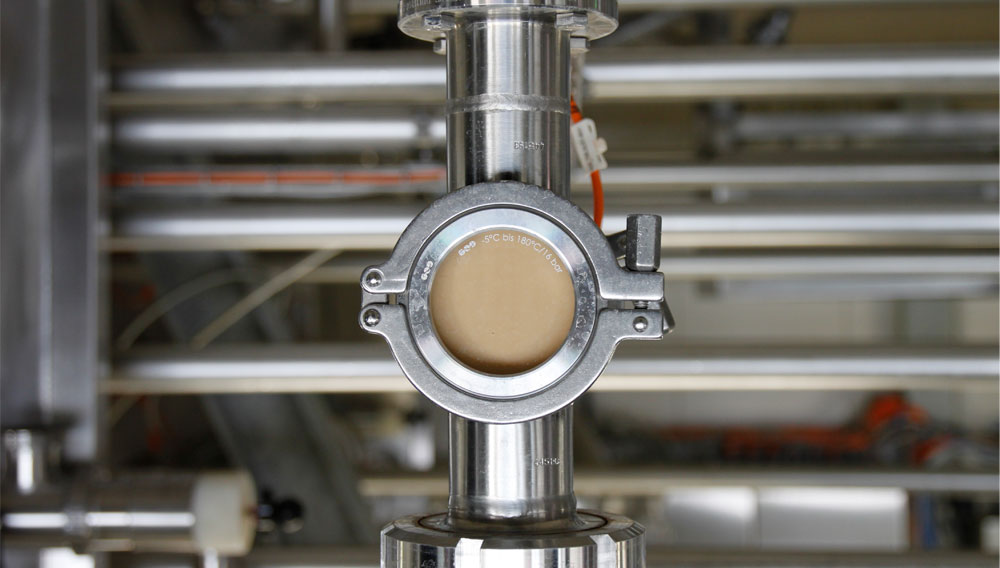

Higher flexibility | Consistent yeast propagations are a challenge in production environments with changing brewing schedules, downtimes, and delays. Propagation protocols that run based on a timer are not flexible. It requires additional external lab samples and labor to correct or adjust the propagation protocol. A solution is the use of inline sensors that provide accurate and reliable data to control and run the propagation according to the specifications. The Boston Beer Company (BBC) propagates various yeast strains with a “Pitch & Pull” strategy, where the propagators do not receive a CIP after multiple pitches until switching to another strain. Under these circumstances and after trialing multiple sensors, BBC successfully tested an extract sensor from Anton Paar that met all expectations and decided to move forward with the installation of these sensors for all BBC locations.

Fermentation/Maturation

Yeast storage | The availability of a large amount of pitching yeast complying with the required viability and fermentation performance is an advantage during the time-critical run-up procedure after a brewery shutdown. This article describes the evaluation of pretreatment, storage conditions and re-activation technique of a lager yeast to conserve maximum viability and fermentation performance.

Fermentation/Maturation

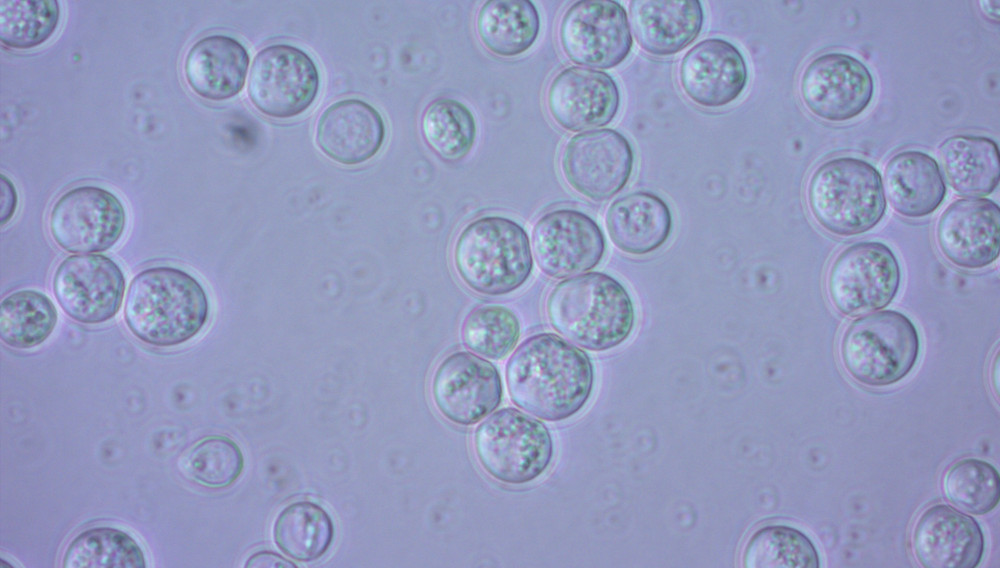

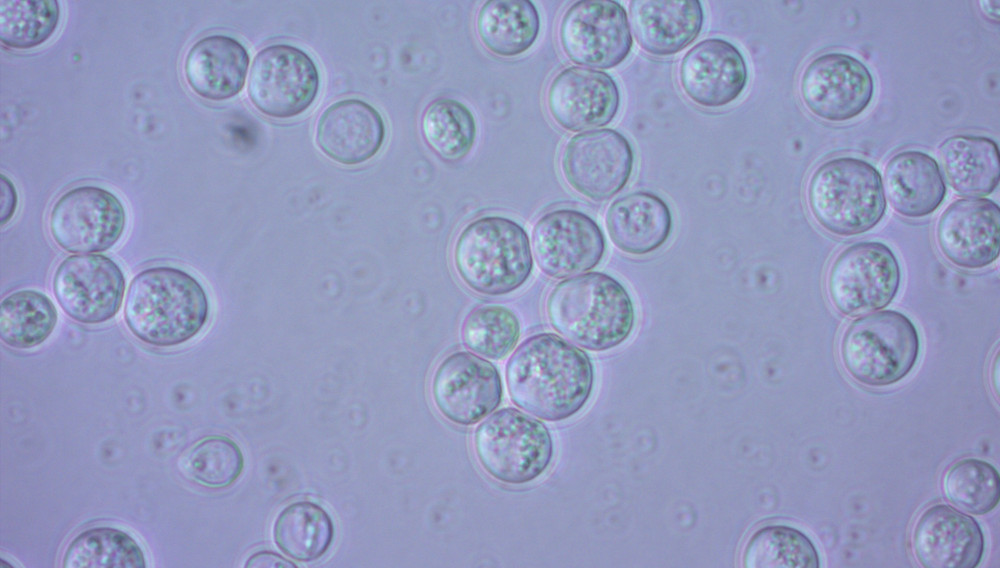

Use in beer production | Although several non-Saccharomyces yeasts have been examined for beer production, M. pulcherrima, which could be a potent alternative yeast, has not yet been tested. This article demonstrates the ability of commercial M. pulcherrima wine yeast to metabolise wort sugars and produce beer with desirable characteristics.

Filtration

Further innovation | BrauKon GmbH, a globally renowned brewery equipment manufacturer, operates its own 50 hl brewery, Camba Bavaria, in Seeon, Bavaria, in addition to fabricating its own equipment. This combination of engineering and brewing under one roof is unique: 120 employees, 36 of them brewmasters and engineers, test and optimize all BrauKon products in the process of brewery operations. The equipment manufacturer, which claims to be the market leader in hop technology, has already launched the second generation of its successful cold hopping system, the “HopGun® 2.0”.

Management

Data analysis | Increasing digitalisation makes it possible to collect and analyse copious amounts of data with multivariate cause-and-effect relationships. However, brewery operations face major challenges when attempting implementation on their own. This contribution presents findings and solution pattern from the research project “Data-driven Process Optimisation using Machine Learning in the Beverage Industry” (DaPro).