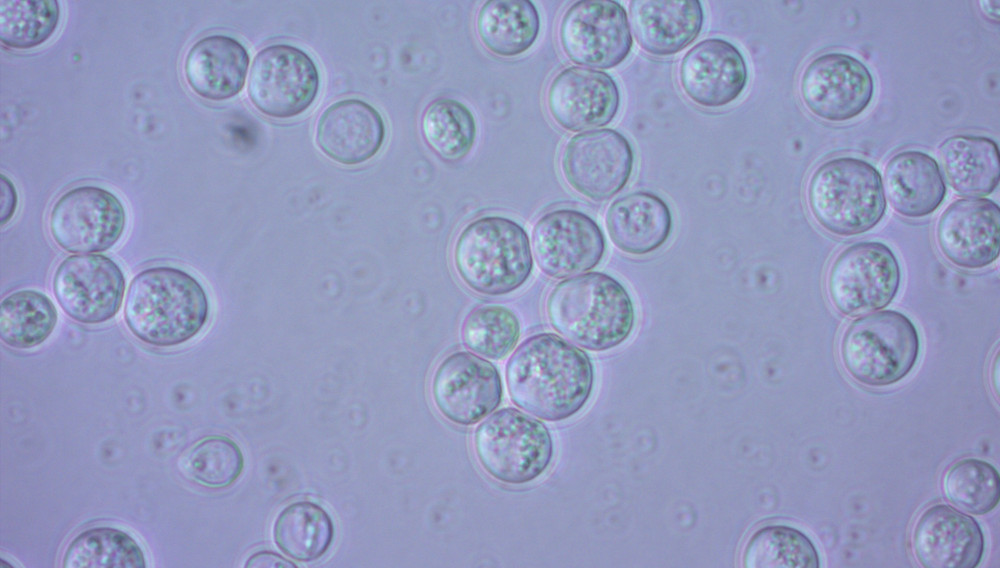

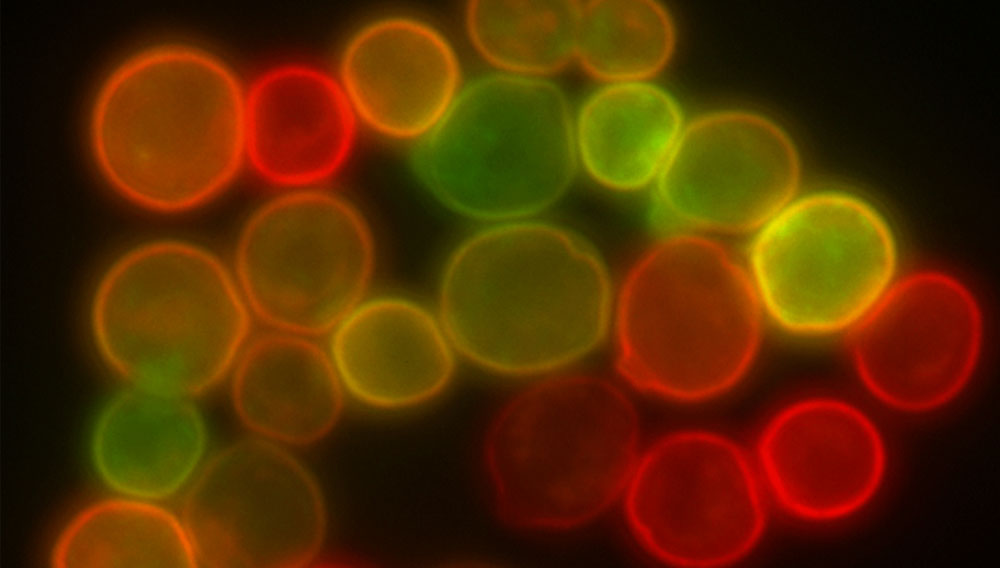

Molecular basis | Flocculation is an important facet of yeast behavior which is widely exploited in the brewing industry as an effective, low cost and natural mechanism for yeast removal from beer. This review aims to briefly summarize the current understanding of the underlying molecular biology involved in flocculation, as a condensed version of the review article “Molecular Basis and Regulation of Flocculation in Saccharomyces cerevisiae and Saccharomyces pastorianus – a Review” originally published in BrewingScience, 74 (March/April 2021).

High seas and world records | The first installment in this series (BRAUWELT International no. 1, 2022, pp. 30–34) followed the trail from the creation of the wooden beer keg to its role in the Hanseatic League and in sea voyages during the Age of Exploration. The second installment (BRAUWELT International no. 2, 2022, pp. 135–137) was devoted to recounting the struggle seafarers faced against the disease scurvy. In this final installment, Dr. Markus Fohr discusses the beer produced on modern cruise ships and how the wooden barrel has found its way into our language and even into world records.

Manuka beer | The first installation in this three-part series (refer to BRAUWELT International no. 1, 2022, pp. 30–34) described the origins of wooden beer barrels in antiquity, their use by the Hanseatic League and on sea voyages during the Age of Exploration. Those who sailed the Seven Seas were often confronted with an uninvited guest: scurvy, an insidious disease caused by vitamin deficiency. Part 2 in this series is devoted to the topic of how sailors fought scurvy and the crucial role played by spruce beer in doing so ...

A Seaworthy Transport Container | BRAUWELT author Dr. Markus Fohr takes us on the wild barrel ride that beer has taken through history. He begins part 1 on the “path into the woods” with the invention of the wooden barrel and its role in antiquity up through to the sea voyages in the Age of Discovery.

Yeast biodiversity | During the Corona crisis, some brewers used free capacities for product development. Novel maltose-negative yeasts from the “Hefejagd” (Yeast Hunt) project of the Research Center Weihenstephan formed the basis for more yeast biodiversity. This contribution looks at the tried and tested production of a non-alcoholic beer using Saccharomycodes ludwigii and analyses the yeast strains Cyberlindnera misumaiensis, Cyberlindnera saturnus as well as Kluyveromyces marxianus and their properties.

Developers want feedback | On October 1, 2020, Dr. Mark Schneeberger assumed leadership of Application Development Beverage & Beer at GEA in Kitzingen, Germany. He succeeded Dr. Rudolf Michel, who went into well-deserved retirement at the end of March 2021. BRAUWELT interviewed Dr. Schneeberger about his new position, one year on.

Eye-catching fermentation vats | It’s not only true of top-fermented beer styles that fermentation in a low, open tank enhances their taste and aroma. Tanks of the latest generation are made of stainless steel and fully automatically CIP-able – and can thus be used in 21st-century breweries without any reservations whatsoever. They have the ability to lend beer an emotional appeal that fascinates consumers.

Still on the up | As brands look to appeal to a growing group of ‘sober curious’ consumers, hard seltzers – alcoholic beverages containing carbonated water, alcohol and often with a fruit flavoring – are well placed to meet these demands. Hard seltzers present exciting opportunities for brands to differentiate their portfolios, but how can brewers overcome the new formulation challenges brought by hard seltzers while ensuring great-tasting beverages every time?

Promising alternative | Non-alcoholic and low-alcohol beers with a significantly reduced alcohol content are currently en vogue and meet the increasing health-conscious mindset of consumers, without having to forego the pleasure of drinking. Against this backdrop, many brewers are confronted with the question: is it possible to produce non-alcoholic or low-alcohol beers using existing equipment?

Yeast research in focus | The 4th BrewingScience Yeast Special will be published on April 29, 2022. The call for papers is open now.

The alcohol-free beer trend | After almost 30 years the Bavarian State Brewery Weihenstephan has invested in a new de-valcoholisation plant. This sets the oldest brewery in the world up for the future and enables it to perfectly cater for the growing demand for alcohol-free speciality beers. Greater productivity, flexibility and the use of cutting-edge technology were what triggered the decision to place the order.