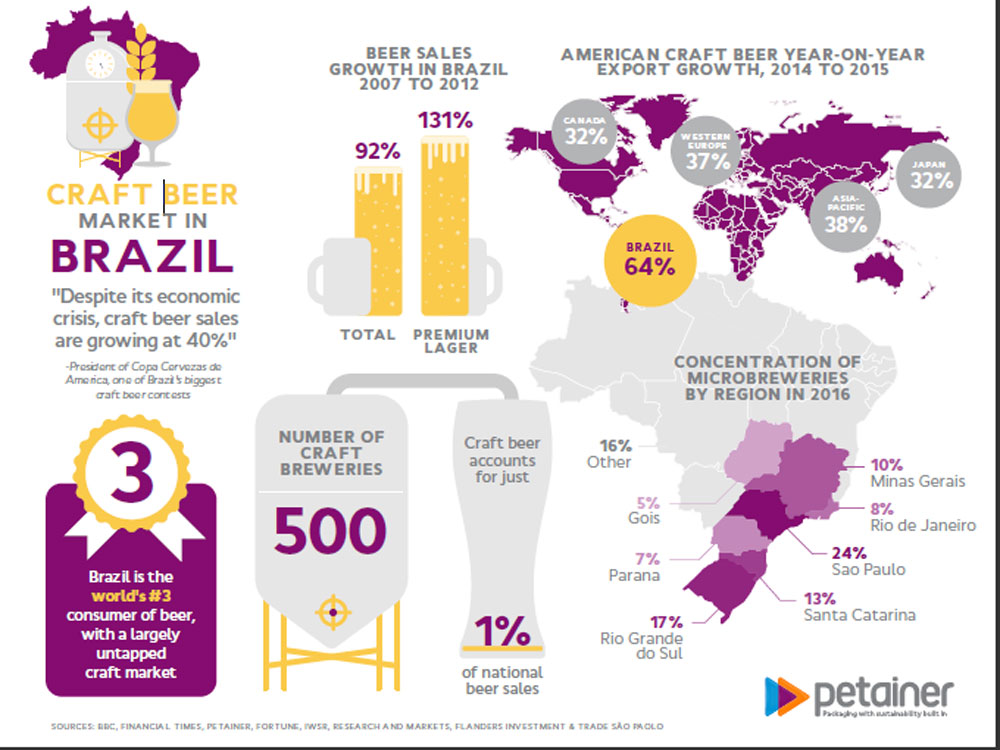

The plastic packaging supplier has launched a stand-alone business in Brazil as part of its growth strategy for the Latin American region. The company is targeting the rapidly growing craft brewing sector in Brazil and large regional brewers with its one-way PET kegs.

As breweries grow and build their brands, many seek to expand their outlets and exploit new markets with an export strategy. However, taking beer from one market to another often presents breweries – large and small – with a number of marketing and supply chain challenges. Nevertheless, by following some simple guidelines, breweries can avoid common pitfalls and make exporting a success.

Sidel is helping beverage producers to maximise cost efficiency while simultaneously improving sustainability with Eco Booster, a service suitably developed for customers already operating Sidel blowers. Eco Booster, part of the Sidel Services portfolio, can provide measurable savings by reducing the consumption of materials, electricity and compressed air.

Key performance metrics for efficiency are established tools for quantifying bottling line performance. They provide a comparison of ideal volume and actual production volume. Expressed as a ratio, this figure can be used to quantify production losses. However, as is frequently the case, the devil is in the details; therefore, selecting the correct metric is essential.

The new Sidel StarLiteTM Tropical base is enlarging the family of StarLite bottle solutions. This latest addition is designed to offer a flexible solution for carbonated soft drinks (CSD), in all packaging sizes from 0.25 to 3 litres. Additionally, it is applicable to the different standard levels of carbonation. It is specifically designed for CSD bottles undergoing harsh conditions – for instance when produced and distributed in the supply chain at very high temperatures or in environments which are particularly humid. The end result is a PET bottle that offers improved resistance in terms of stress cracking and creeping, as well as better stability throughout the supply chain.

Logoplaste, Cascais, Portugal – a leading global manufacturer of rigid plastic packaging in the food and beverage sector – is benefiting from Sidel Services Online. This new, user-friendly web interface maximises line uptime by providing fast, easy and reliable online searching for Sidel original spare parts. The interface also gives customers a comprehensive online view of their existing Sidel equipment with access to technical documents and e-catalogues.

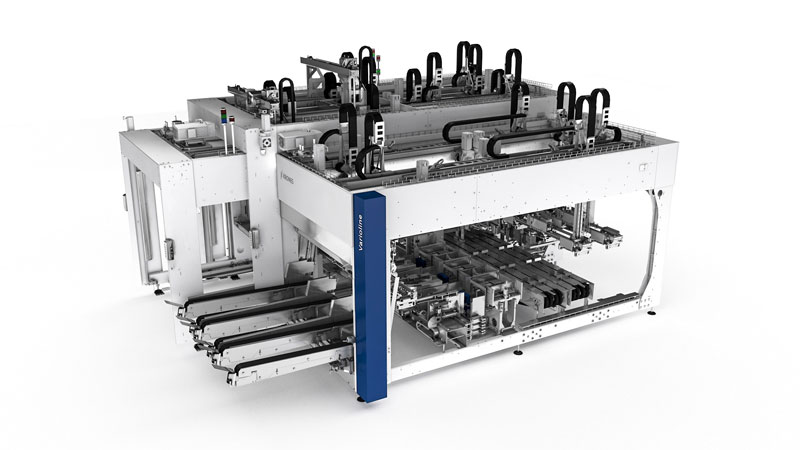

The Varioline packaging system by Krones has proved highly successful in establishing itself within the beverage industry. As evidenced by more than 30 machines commissioned within a period of just two years. For the brewing and beverage industries, flexibility in end-of-the-line packaging is an increasingly important consideration. The basic idea involved is that a single machine replaces up to six conventional individual machines linked by conveyors. With the Varioline combination conjuror, packaging processes involving up to three stages can be handled by just a single machine. The modularised Varioline kit consists of three modules, which can be combined to form a customised packaging system. These three units, the cartoning, feed and basic modules, feature an identical basic construction, to create a modularised design concept that ensures flexibility for the future.

Gebo Cermex, a supplier of innovative packaging line solutions, has received the official mark “Vitrine Industrie du Future", awarded by the Alliance Industrie Du Futur (AIF) in recognition of its efforts to introduce, develop and implement Industry 4.0 initiatives at its plant in Saint Laurent sur Sèvre, France. On receiving the award, the company has highlighted the importance of investing in Industry 4.0 possibilities to build long term competitive advantage. This mark is awarded by AIF to companies that implement new tools such as digital data exchange and advanced robotics to drive the transformation of business models and organisations as well as design and marketing methods.

A brewery rich in tradition, Brauhaus Riegele in Augsburg, Germany, brews a total of 29 different beers. Almost all of the beers have been honored with numerous prestigious awards. In order to ensure that the beer leaves the brewery in perfect condition and remains so until it reaches the customer, the oxygen values must be reduced to a minimum and continuously analyzed, in this case with oxygen measuring devices supplied by Dr. Thiedig GmbH & Co KG, Berlin, Germany.

Petainer has launched a range of new rental agreements for filling and blowing lines to help customers take full advantage of the petainerKegTM system.