It has never been more important to stand out from the crowd than in today's competitive beverage market. Labels are key components of any brand marketing mix, allowing manufacturers to differentiate their products and give end consumers the information they need and increasingly expect.

Homogeneous | In November 2017, the private brewery Erdinger Weißbräu Werner Brombach GmbH, Erding, Germany, inaugurated a new bottling line. The brewery also invested in a new central sorting facility, which ensures the supply of all three filling lines with pure empties.

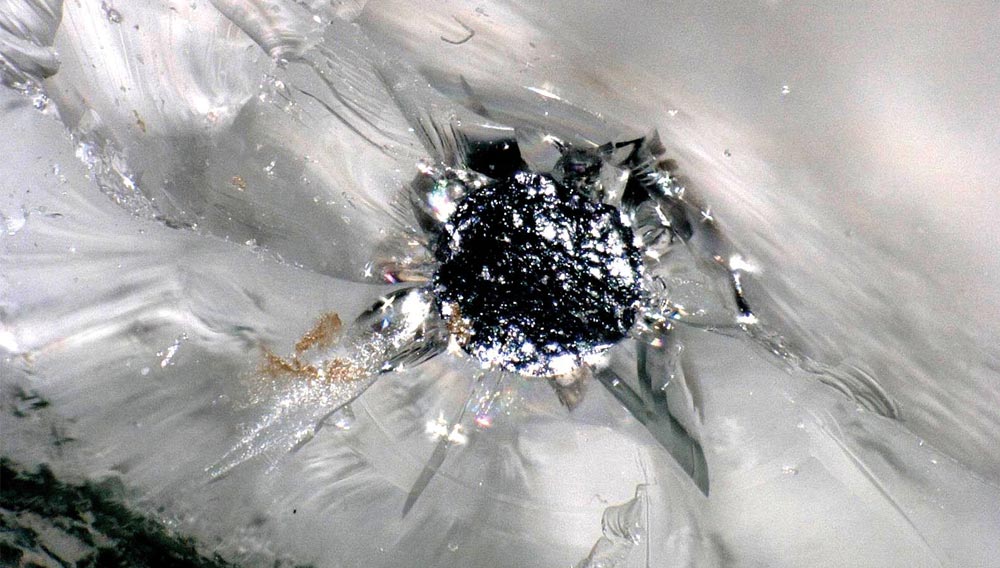

Heart of Glass | No other material is as beloved as glass for packaging sensitive beverages like beer. Glass is odorless and tasteless, inert with respect to the product and completely impervious to gas. These are just a few of the many advantages of glass as a packaging material.

After recently expanding its presence in the North American beverage market, Lightweight Containers BV, the company behind the UniKeg and KeyKeg one-way kegs, has announced a strategic agreement with Micro Matic, manufacturer and supplier of keg valves and dispensing equipment. This agreement was set to begin March 1, 2018, and marks the first time KeyKeg dispense couplers will be able to dispense with pressure up to 4.1 bar, instead of 3.5 bar, while affording users the option to vent KeyKegs quickly and easily with the flip of a switch.

Grippy lightweights | The water market is growing worldwide. How beverage producers are meeting the increasing demand and preparing themselves for future growth in this segment is illustrated by the example of the Butsifal Group in Uzbekistan. With a high-performance KHS filling and packaging line for PET bottles the beverage producer founded in 2009 is challenging the supremacy of local market leaders and even doing business beyond its own national boundaries.

The PET packaging supplier has appointed three new distributors in Europe, expanding its footprint in the region. The new distributors are Ice Techic in Bulgaria, BrewTec Europe in France and Scangothia in Sweden.

For limiting torques in indirect drives of bottling and cleaning plants, packaging machines, etc. Enemac supplies a special stainless steel version. The type ECR complies with the strict hygienic requirements in food-processing, pharma and medicine industry.

The glass and metal packaging company was again rewarded for pushing the boundaries of metal packaging with a series of awards at the prestigious annual Canmaker Cans of the Year event.

The packaging line engineering and material handling solutions specialist Gebo Cermex, part of the Sidel Group, has recently signed a supply agreement with Kuka AG. The contract was finalised in Munich at drinktec 2017. Putting pen to paper for the agreement were signatories Mr. Marc Aury, President and Managing Director of Gebo Cermex and Mr. Joachim Melis, VP Division Consumer Industries & Handling of Kuka, representing the German manufacturer.

For over 60 years, beer has been filled into cylindrical beer barrels – kegs – and is dispensed in the catering industry, at events and other occasions. As kegs are designed for frequent re-use and longevity, only specific forms of damage can render a keg completely useless. In almost all instances, damage can be repaired, maintaining product quality, customer satisfaction and filling line efficiency at a high level.