100% rPET | Sidel’s art designers have created the Nuuk bottle concept, drawing inspiration from the purity of ice and its formations. Produced from clear, 100% recycled PET (rPET), Nuuk is a container designed for high-quality, fjord-sourced premium water brands.

Barrier technology | The Bundesrat (upper house of German parliament) recently voted in favour of extending the mandatory deposit on containers to cover all non-returnable plastic bottles and beverage cans.

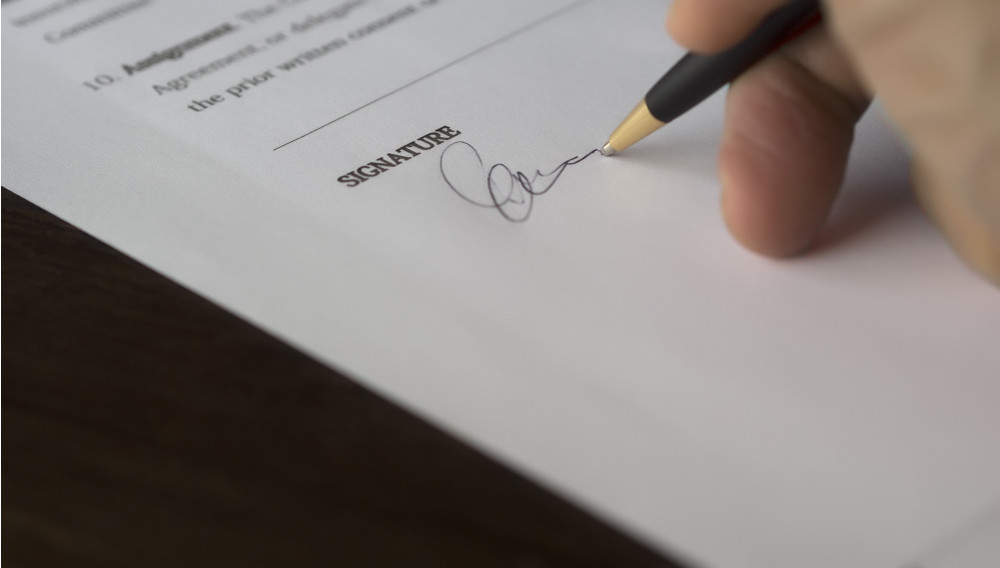

Solutions for the glass market | O-I Glass, Inc. Perrysburg, Ohio, USA, and Germany’s Krones AG, Neutraubling, Germany, signed a strategic collaboration agreement that aims to elevate glass by innovating together and to jointly create solutions for the growing glass market.

Individual solutions for glass packaging – presented at the Beviale 2020:

Hightec-objects with cultfactor. Not only for the younger target group, the perfectly designed tinplate packagings from Kleemann are in full swing.

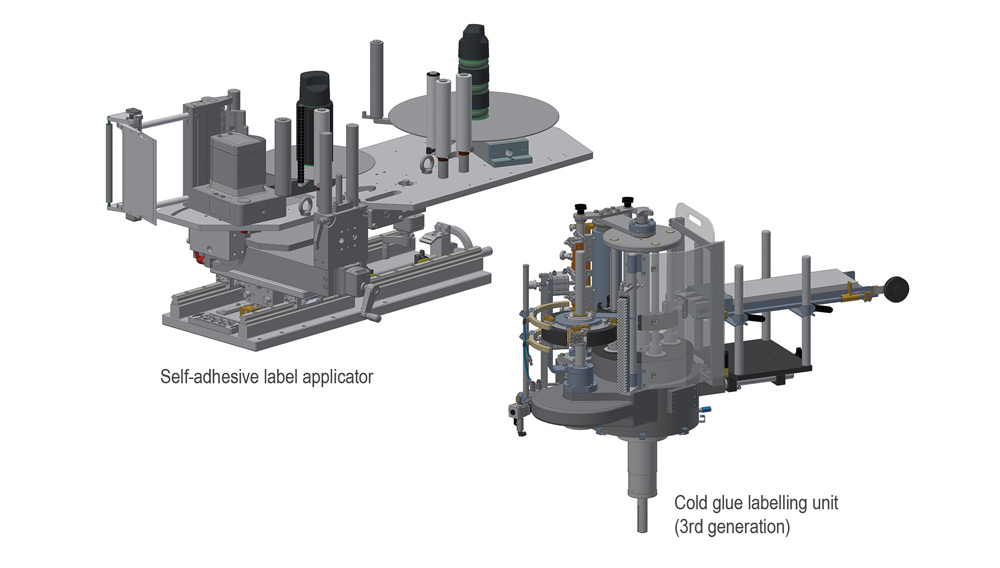

This year the labelling machine manufacturer GERNEP introduced two new aggregates for its gluing systems onto the market: The GERNEP self-adhesive label applicator and the 3rd generation cold glue labelling unit.

Sustainability | With its Plasmax coating technology and the FreshSafe PET® packaging system which has evolved from it, KHS offers the food and beverage industries a sustainable, environmentally-friendly system with a particularly good product protection. Today’s coating system for PET bottles dates back to the 1990s when it was used in the pharmaceutical industry. How has this extraordinary story of success come about?

Sidel | Producing a great diversity of bottles from 0,5 L to 1,5 L on a single packaging line for PET, Pearlwater Mineralquellen AG, Termen, Switzerland, was determined to enhance the efficiency of its production line as well as bottle quality by upgrading its PalKombi Gripping palletiser’s performance, installed by Sidel in 2011. Trusting in its OEM, Pearlwater were able to increase the palletiser’s reliability and flexibility for the handling of various pack sizes and improved overall line efficiency by 5% with better pack and pallet stability.

Krones | On 25th August, the German Packaging Institute announced Krones AG and its subsidiary, Dekron, as winners of the German Packaging Award 2020 in the category “sustainability”. The prize-winning entry involves a beverage bottle, the design and lifecycle of which were comprehensively created in accordance with sustainability criteria.

Ardagh | The global supplier of metal and glass packaging has committed to set science-based targets through the Science-Based Targets initiative (SBTi), a project that aims to encourage corporate climate action for a low-carbon economy.