Packaging combinations from a single source

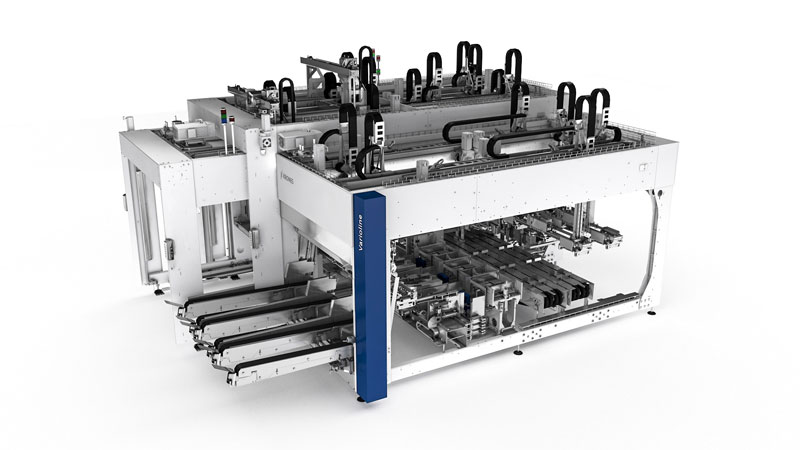

The Varioline packaging system by Krones has proved highly successful in establishing itself within the beverage industry. As evidenced by more than 30 machines commissioned within a period of just two years. For the brewing and beverage industries, flexibility in end-of-the-line packaging is an increasingly important consideration. The basic idea involved is that a single machine replaces up to six conventional individual machines linked by conveyors. With the Varioline combination conjuror, packaging processes involving up to three stages can be handled by just a single machine. The modularised Varioline kit consists of three modules, which can be combined to form a customised packaging system. These three units, the cartoning, feed and basic modules, feature an identical basic construction, to create a modularised design concept that ensures flexibility for the future.

Varioline Country Number One is the USA, where you will find the world’s biggest market for baskets and multipacks. Most recently, the American brewing conglomerate MillerCoors has now modernised and streamlined its packaging technology. For this purpose, the group has installed two new Varioline packaging systems in each of the non-returnable glass lines at four of its facilities, in Milwaukee (WI), Trenton (OH), Fort Worth (TX) and Albany (GA). The Variolone machines, installed for parallel operation, have replaced the old technology, which was based upon a concatenation of individual machines. With erectors for baskets and cartons, an intermittent packer and a carton closer, this multiplicity of units added up to a highly elaborate and personnel-intensive technology. The total output of the machines pairs installed in parallel is up to 104,000 bottles per hour, comfortably covering the line rating concerned of 72,000 bottles per hour. It packs 12-ounce (0.355-litre) non-returnable glass bottles in 6- or 4-bottle baskets inside outer cartons or in 24-bottle partitioned cartons.