Simulated barrel maturation | How do the aromas and color of spirits develop during barrel maturation? What roles do the degree of toasting and the type of wood play? What is the most practical method for determining the phenolic compounds and the volatile substances in wood, such as higher alcohols, aldehydes, esters and lactones? With gas and liquid chromatography? The authors recreated the process of aging in wooden barrels in the laboratory and analyzed the processes of extraction, color and aroma formation.

For over 50 years the Central European Commission for Brewing Analysis (MEBAK®) has published methods of analysis for raw ingredients, wort, beer and beer-based beverages.

Whiskey, Rum & Cognac | Which woods are utilized for wine and spirits barrels? What does toasting and charring do? Why is wood able to generate such complex aromas, and which key aroma compounds can be extracted through the maturation of spirits in barrels? In a three-part series, the authors describe the development of methods for measuring the characterization of wood-based flavors in spirits. Part 1 introduces the basics of maturation in wooden barrels.

Ensuring product quality | Balancing 400 years of brewing tradition with modern tools and technologies that push the limits of production is anything but easy. Leveraging modern sensor and production technologies to measure everything from wort to bottled beer, the quality control (QC) team at Hofbräu München ensures that Hofbräu München’s beer has its expected taste, complies with regulatory standards, and meets high quality standards. And it does this with Anton Paar instruments.

Visual foam stability | The quality of beer foam depends on many factors, including initial foaming, head retention, lacing and so on. Most foam analysis methods focus mainly on head retention. Using such methods, foam membrane strength for head retention was shown to be an important aspect. Could this factor be responsible for head retention only? And what role do hop bitter acids play in this? The following article summarises some research results which have already been published in BrewingScience, 2021, issue 6: November/December.

A new analytical approach | The contribution of different malt types to the beer aroma is traditionally assessed by trial-and-error testing in pilot scale. In this article, we describe a new analytical method that shows promising results in predicting specific aroma properties of bottom-fermented beers based on the analysis of marker volatiles in the malt mixtures applied for brewing without the need for extensive brewing trials and beer sensory evaluation.

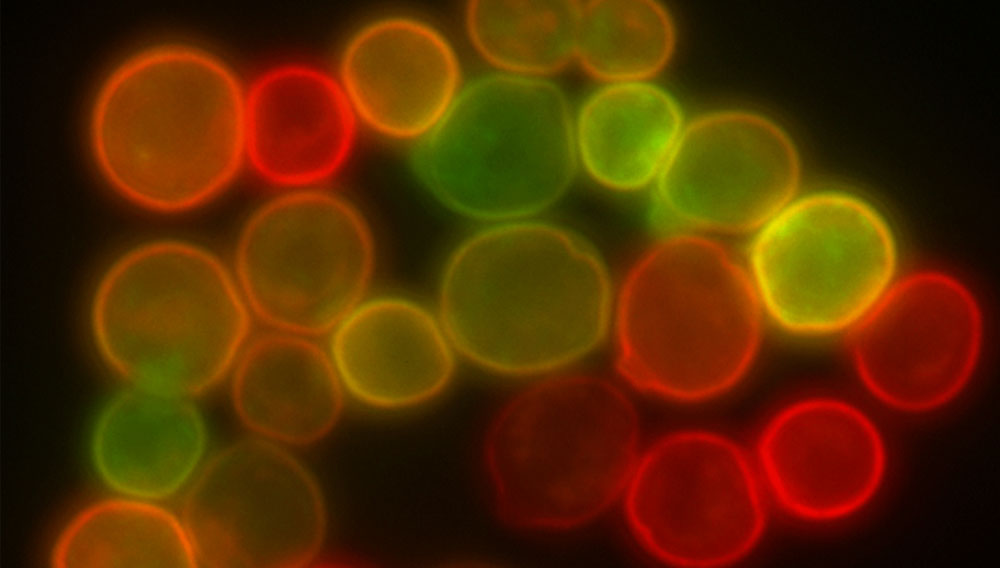

Molecular basis | Flocculation is an important facet of yeast behavior which is widely exploited in the brewing industry as an effective, low cost and natural mechanism for yeast removal from beer. This review aims to briefly summarize the current understanding of the underlying molecular biology involved in flocculation, as a condensed version of the review article “Molecular Basis and Regulation of Flocculation in Saccharomyces cerevisiae and Saccharomyces pastorianus – a Review” originally published in BrewingScience, 74 (March/April 2021).

Pure malt grist | To help businesses facing the challenge of rising costs and fluctuating raw material qualities, Bühler introduces its innovative DDH Dry Dehusking technology. By replacing the hammer mill with a roller mill in mash filter applications, the new system increases brewhouse capacities, compensates for different malt qualities and allows for significant energy savings, less wear and reduced risk of explosions.

Empty bottle inspection | The VLB proof of performance test for empty bottle inspection machines is a method for assessing the detection performance of inspection machines and identifying potential areas for optimization. Furthermore, analysis of the data gathered over the last ten years provides an insight into the development of detection performance and enables conclusions to be drawn as to which conditions need to be created for commissioning in order to be able to exploit the full potential of new empty bottle inspectors.

Barrel ageing | In recent years, maturation of beers in wooden barrels is becoming an interesting avenue for breweries to expand and refine their beer portfolios. Especially in the craft beer sector there is an increasing consumer demand for more complex flavours and aromas, many of which can be obtained through barrel ageing of beer. However, microbial spoilage of the barrel has to be effectively controlled in order to ensure consistent product quality and reduce profit losses.

CO2 quality | Many breweries purify their fermentation carbon dioxide and reuse it. Unfortunately, in conventional CO2 purification plants, not all flavour substances potentially still present are removed and remaining ones could be carried over into the beer when purified carbon dioxide is reused. Carry-over of off-flavour impurities may be prevented by installing the MPlus PC02 from Parker, thus extending the recovery plant.