Filtration

New method | ß-glucans have a negative effect on filterability, haze and lautering but also a positive physiological aspect as well as a positive effect on beer foam. Though high molecular weight (>100 kDa) fractions are primarily held responsible for the negative aspects, it has not yet been possible to describe the fraction responsible for influencing beer foam.

Filtration

Clearly a good idea | Wort and subsequent beer clarity is still of importance to the brewer and beer consumer. Even for beer styles and brands where a certain level of haze is accepted or even expected, understanding and control over the process is critical for the brewer. The use of carrageenan-based kettle finings historically referred to as copper finings is practically ubiquitous for brewers in the UK and most of the USA. However, in the rest of Europe the use is much more mixed. The manufacture and use of kettle finings are discussed in this article to explore if some brewers are missing out.

Filtration

In early November 2018, the Fareham-based filtration and separation specialist announced the addition of the CompfilTM range of compressed air filtration to its liquid, air and gas filtration products.

Filtration

CFS Neo membrane technology | Membrane Technology is gaining increasing share in today’s beer production process. Whilst crossflow filtration is now well established compared to traditional kieselguhr filtration, “sterile” membrane filtration of beer has a way to go, but the trend is shifting.

Filtration

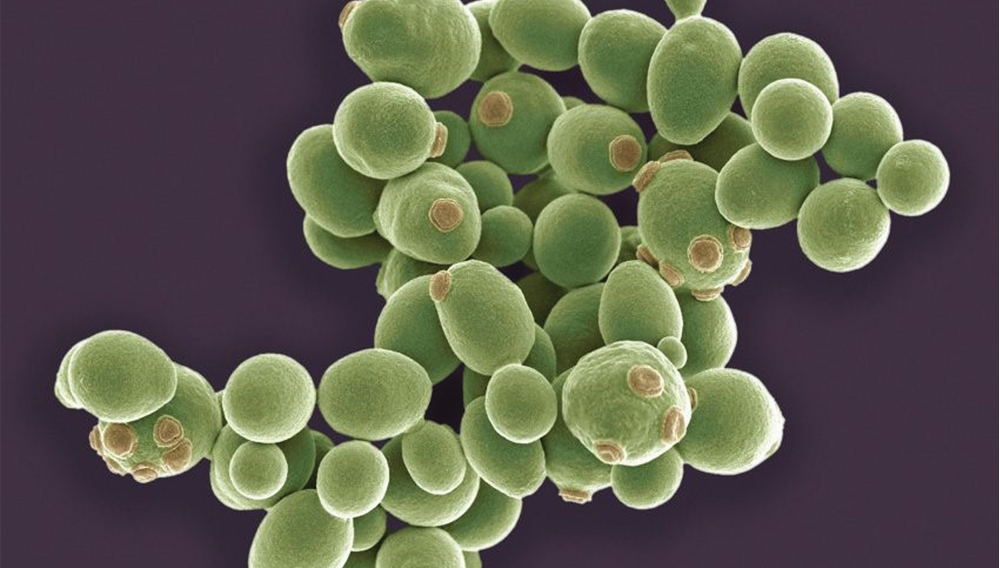

Key to beer quality | At first glance, handling and the role of yeast in a brewery seem to be easy to deal with: yeast ferments the sugars of the wort, producing alcohol and CO2 in this process.

Yeast can be harvested and recycled. When examined in more detail, matters become more complicated and have a much stronger influence on beer quality than generally assumed. As such, handling and a proper understanding of yeast is a reflection on beer quality.

Filtration

The Fareham-based group acquired on 1st March Keystone Filter, a division of CECO Environmental Corp (CECO). The group has acquired the goodwill, business and trading assets of Keystone for cash.

Filling

After the fusion of Bucher Filtrox Systems AG and Bucher Unipektin AG at the beginning of 2017, a new department – Competence Center Filtration – was founded.

Filtration

The Central European Commission for Brewing Analysis (Mebak) held its 90th general meeting in Linz (Austria) in October 2017 at which it agreed to fully revise the guidelines for control of brewhouse operations.

Filtration

Advantageous process | Cold stabilisation of beer, also referred to as sterile filtration, can return significant cost savings over pasteurisation. In addition to providing an increased level of microbial security and better protection of beer quality, it is by far the most efficient process to operate in comparison to pasteurisation from a cost perspective. These cost savings, whilst significant, may not be widely understood or appreciated in what has traditionally been a conservative industry. Given the challenges facing brewers today, this article will share insights into the four main areas where cold stabilisation returns significant cost savings over flash pasteurisation.

Brewhouse

Development of the new Nessie by Ziemann lautering system for mash separation is an interesting innovation for the overall techniques and technology of beer production. This paper will present the technological contexts and impacts on surrounding unit operations as well as the effects on wort quality, the ultimate outcome of brewhouse work.

Filtration

The Filtration Division of the power management company Eaton has developed a new BECO filter cartridge range that can be combined to provide effective pre-filtration and final filtration for stable and bright beer.