Filling

Greenfield project | Following long years of contract-bottling, the smoothie and juice producer innocent has decided to build the very first bottling plant of its own. Krones won the order for four complete PET bottling lines and the corresponding IT landscape.

Filling

Sidel | One of India's foremost private sector companies, ITC, recently introduced a brand new range of milk-based drinks with fruit pieces while expanding their juice portfolio with a variety of premium 100% Indian fruit, 0% concentrate and 0% preservative juices. With both they trusted Sidel and their proven expertise in aseptic packaging, investing in a complete line, featuring the first dry preform sterilisation in India.

Filling

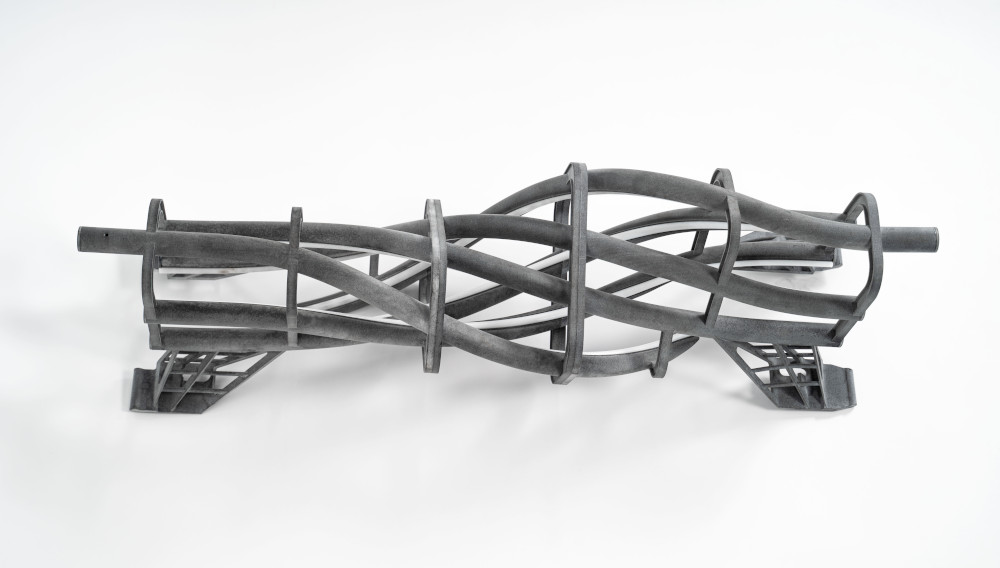

Multifarious chances | Krones AG, Neutraubling, Germany, is convinced: generative part and component manufacturing offers multifarious chances and opportunities for the mechanical engineering sector.

Filling

Gawis 4D | Agr International, Inc., Butler, USA has unveiled their latest development, the Gawis 4D™, an all-in-one measurement system for plastic containers and preforms.

Filling

Sidel | Two years after the introduction of the Super Combi to the industry for compact lines’ solutions, Sidel presents a bolder, next-generation solution Super Combi Compact thatis even more compact with a 30% faster filling performance.

Filling

Sidel | Installed for the very first time in its largest size at Orangina Suntory France’s plant in Meyzieu, Sidel’s conveying and accumulation solution Gebo AQFlex® increases the uptime of their PET packaging line for soft drinks by offering a high level of flexibility to address a much diversified production range of nine bottle formats with different shapes.

Filling

Adequate solutions | As beer alternatives with low alcohol concentration or completely without alcohol are becoming increasingly popular worldwide, equipment manufacturers aim to provide their customers with adequate solutions, which take into account the importance of the raised hygienic conditions for these types of drinks.

Filling

Field test | In spring 2019, the Bavarian brewery Aying Franz Inselkammer KG, Aying, commissioned a newly developed process combining a bottle washing machine (BWM) with a high-temperature heat pump (HTHP) and the existing co-generation plant (CGP).

Filling

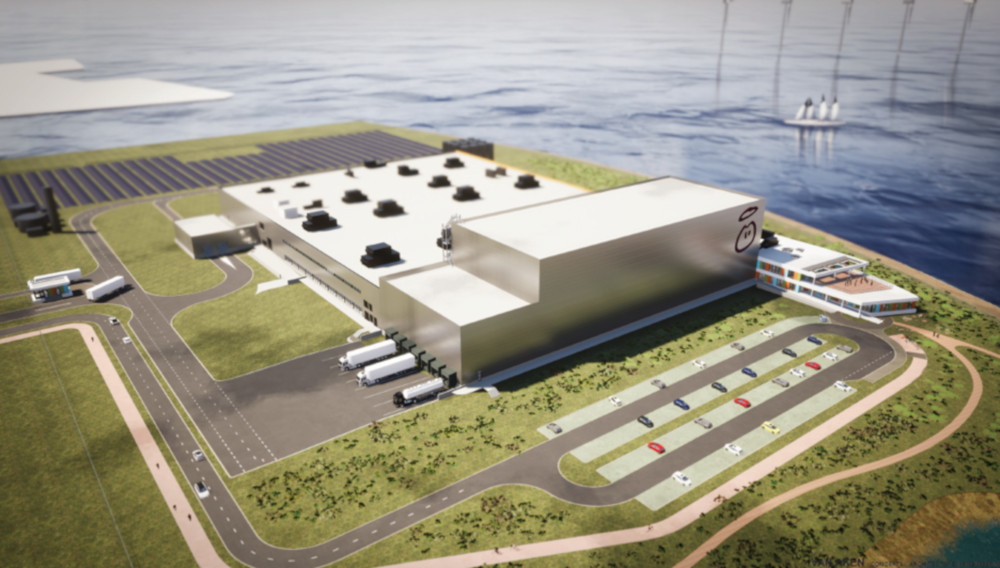

Aseptically packed | Niche Cocoa Industry Ltd., Ghana’s largest fully integrated cocoa processor, recently signed a deal with Sidel with the intention to advance into previously uncharted territory: beverage production. The company are planning to support Ghana’s School Feeding Programme by providing 5.6 million pupils with ready-to-drink (RTD) chocolate milk, aseptically packaged in 250 ml PET bottles, for 100 school days per year.

Filling

Agr International, Inc | Automated Blowmolder Control systems take the guesswork out of the blowing process.

Filling

Global Data | Small scale breweries could run short of CO2 due to a significant shortfall of the production of this gas caused by the struggling oil industry.