Generative manufacturing: Layer by layer to a finished component

Multifarious chances | Krones AG, Neutraubling, Germany, is convinced: generative part and component manufacturing offers multifarious chances and opportunities for the mechanical engineering sector.

In the industrial sector, 3D printing ranks among the major issues for the future, alongside robotics, digitalisation and machine learning. In this process, also known as additive or generative manufacturing, a 3D model created in CAD is converted into two-dimensional layers, which are then applied successively during printing. Components from the 3D printer can already be found today in products of the automotive industry and aircraft manufacturers, and in the field of medical technology. But is the process also suitable for line manufacturing, particularly the customised machines in the beverage and liquid-food industries? Or do their small batch sizes and large-scale product individualisation prove to be limiting factors?

Krones AG, Neutraubling, Germany, has been addressing these issues for several years now, and is convinced: generative part and component manufacturing offers multifarious chances and opportunities for the mechanical engineering sector. This is because with 3D printing even minuscule batches, e.g. when producing prototypes, can be cost-efficiently manufactured. For spare parts supply covering older generations of machines, this aspect is likewise of interest. After all, the parts no longer need to be placed in storage; instead, after design modifications they can be reproduced at short notice, without needing any specially manufactured tools and ideally even at decentralised locations. The client benefits here not only from fast availability, but also from components customised to suit his own machine.

But for implementing 3D printing applications of this kind, there are quite a few factors to be taken into due consideration: the generatively manufactured components have to withstand the stresses encountered during the production operation, and depending on the application category involved the material requires a high mechanical and chemical load limit. “Every part installed simply has to meet Krones’ stringent equipment performance stipulations. These include not only stability, but also the material’s elasticity and resistance to cleaning agents,” says Reinhard Ortner, explaining the production technology for generative manufacturing at Krones. “For this reason, we have focused on a combination of application categories, materials and printing processes. In development projects, we thereupon manufactured a variety of parts and components in a 3D printing process, so as to test them for industrial use.”

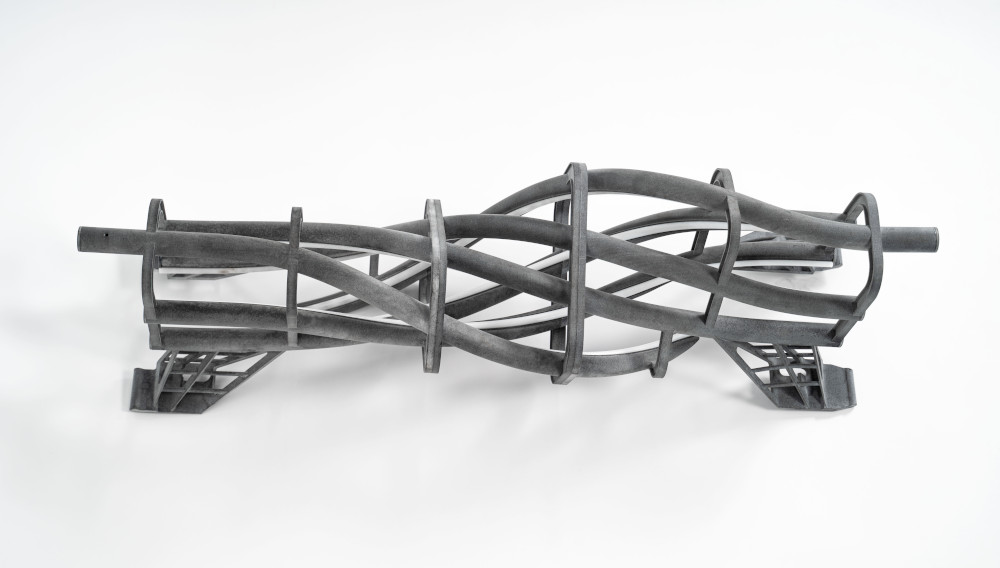

Can inverter from the 3D printer

One of these projects, for example, is a can inverter from the 3D printer. “Generative manufacture of a can inverter poses quite a few challenges. The development team had to analyse a multiplicity of points, like the kinematics involved, meaning the optimal motion sequence of the cans as they are inverted. Then there were also the tribological characteristics, meaning the friction behaviour between the cans and the material,” explains Andreas Neuber, a technology expert on additive manufacturing. The basic material chosen was accordingly simple but performatively excellent, and combined with a particularly sturdy wear profile. “Several attempts were needed for the development work, of course. The 3D model of the can inverter adapted for additive manufacturing was designed in CAD, and then printed. In the test, it quickly emerged what modifications were needed, and these could be swiftly implemented,” relates Andreas Neuber.

The result is a 3D-printed can inverter that thanks to generative manufacturing can offer a significantly shorter procurement time. Another advantage: with conventional can inverters, in particular, shaping deviations are invariably encountered due to manual machining. With 3D printing, the ideal can guide configuration can be reproduced as often as you like and can in addition be quickly and easily adapted to handle new container formats. Project Manager Thekla Herrmann adds: “In the next step, the can inverter will be subjected to rigorous trialling in a field test. In the next few months, we shall see how it performs there.”