Corona crisis | In the fight against COVID-19, Sidel have transformed their international centre of excellence for PET packaging development and blowing solutions in France into a production centre and launched an exceptional production of bottles for hydro-alcoholic gel.

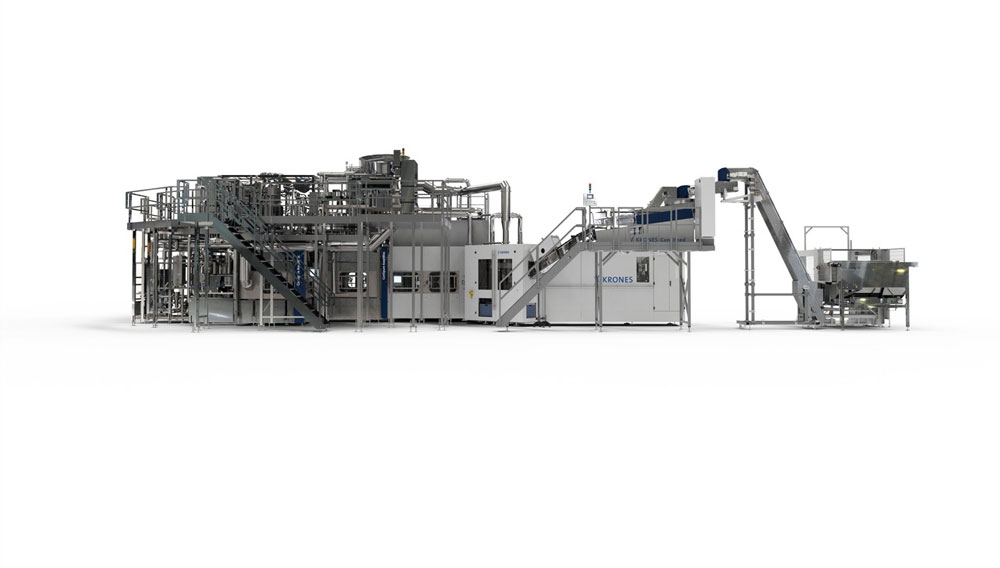

Krones | The Contipure AseptBloc DN at the Austrian food and beverage producer Spitz uses gaseous hydrogen peroxide for sterilisation, and can handle 24,000 containers per hour.

An exemplary plant | Heineken and KHS are setting standards with the newest and one of the biggest breweries in Mexico on all counts: besides its impressive proportions the plant is also a shining example when it comes to ecological and economic sustainability.

Focus on brewers’ yeast | Microbiological detection of foreign yeasts in the brewing process is an important part of hygiene monitoring in breweries. A novel DNA extraction and Real-Time PCR process might help here. This process can reliably detect S. cerevisiae var. diastaticus contamination, without previous enrichment.

Cradle to cradle | Businesses around the world are under pressure to operate as sustainably as possible and the global brewing industry is no exception. Understandably, the use of packaging is under the spotlight in terms of supply chain benefits, product protection and with the rise in consumer environmental awareness the packaging end of life and re-use. Reduction in the use of plastics, recycling, was the aim a few years ago but now business models need to move towards a full circular evidenced lifecycle solution.

Patent pending | In this article, a new process for washing returnable bottles – patent pending – is presented. In terms of energy and water savings, it can be viewed as another quantum leap. Data is based on simulations of the manufacturer’s mechanical engineers and calculations of the inventor. The innovative process makes use of a combination of a bottle washing machine (BWM) combined with a high-temperature heat pump (HTHP) and integration into an (existing) cogeneration plant.

Active ingredients and their effects | Which additives are available for bottle washers and how have they been developed? This article explores individual compounds and the purposes they serve in the cleaning process, from special additives for specific cleaning issues to the filtration of caustic. These can offer opportunities for improvement but may also be detrimental.

Optima | Optima do Brasil has entered into a partnership with the Brazilian mechanical engineering company Quality Machines based in Campinas.

Krones | In the field of aseptic filling, Krones’ portfolio includes specialised machines for the various sterilisation techniques and products involved.

Higher Capacity | A growing market for beer has led Bali Hai Brewery Indonesia to install a new canning line, accommodating a higher production capacity while securing the quality of their premium beers. Designed and supplied by Sidel, the line runs at up to 33 000 cans per hour for the 330 ml format, twice as fast as the former one, and features a very compact layout, thus overcoming the Indonesian brewer’s space constraints.

European footprint | The global supplier of PET kegs OneCircle, Den Helder, Netherlands, is expanding its European footprint with the appointment of a new official reseller of KeyKeg and UniKeg in Spain – Bruni Glass Iberia.