Genetic test | Some contaminant yeasts make beer bottles and cans explode. Apart from being dangerous for consumers these ‘diastatic’ yeasts also cause loss of beer batches due to off-flavours, increased alcohol and over-carbonation in products. VTT scientists developed a genetic test for brewers to detect the strains that cause these problems.

Craft Breweries | In mid-April, GEA Group Aktiengesellschaft from Düsseldorf/Germany presented its new GEA Craft Yeast Propagator at the Craft Brewers Conference in Denver, USA. There, BRAUWELT International talked to Torben Bauch, Team Leader Product Management Beverages and Beer, about the new development and the special requirements of craft brewers in terms of yeast propagation and management.

Getting to grips with brewers‘ yeast | Yeast – driving force, flavourist, complex entity and challenger. There is more to this small organism than meets the eye. Controlling brewers’ yeast is primarily essential for beer quality as it has been subjected to some technological transformations in the course of time.

Biosynthesis | It was found recently that brewers’ yeasts not only break down and convert hop aroma substances such as linalool and geraniol during fermentation, they can also form them. Though these processes take place in the microgram range, they nevertheless change beer flavour. This may be influenced by selection of a brewers’ yeast strain [1].

Beer analyses | The Omnium brewhouse concept by Ziemann has been operating successfully for the first time in a German brewery, Schlossbrauerei Reckendorf, since the beginning of April 2018 [1]. In the first part of the technological considerations, the results of brewhouse operation based on process times and data from wort analyses were explained [2]. The repercussions for beer quality resulting from technological factors described will be examined in this second part of the article.

Less is more | When producing beers using ale yeast strains in the pilot plant of the University of Weihenstephan-Triesdorf, fluctuations occurred in sensory quality of 50-l pilot brews. In some instances, beers were described as “lacking body” and as “empty”. It was assumed that this was due to excessive addition of dry yeast. As a consequence, a pilot fermentation process on a 0.5 litre scale was developed in order to obtain information about fermentation rapidly and with little expenditure.

Searching for innovations | Beer, the traditional beverage, is losing many consumers in the face of many new and innovative beverages. Innovations in the beer sector such as novel hop varieties or targeted use of different malts, as well as a great variety of different shandies, have already reversed this trend to some extent [1]. Continuing along the same lines, a method aimed at producing new brewers’ yeasts is presented.

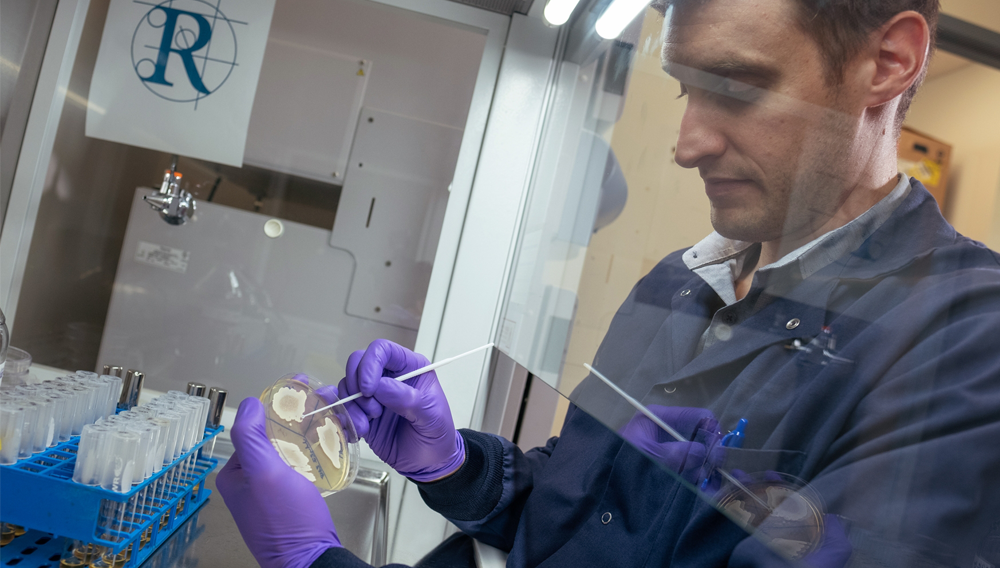

Flavour and aroma variety | Yeast’s impressive natural biodiversity has often been overlooked in modern industrialized brewing in favour of workhorse yeast strains that offer consistency. Today, in an age of rapid expansion in brewing creativity, yeast’s biodiversity is being harnessed to help fuel innovation in beer making.

First International Workshop on Brewing Yeast | Yeast scientists and brewing technologists from all over the world met on 5 - 6 October 2018 in San Andrés de Bariloche, Argentina, to share their latest research findings on brewing yeast.

Designing Yeast | In this concluding section of our three-part series (part 1 and 2 see BRAUWELT International No. 5, 2018, pp. 354-356 and No. 6, 2018, pp. 430-432) we outline the various non-GMO methods by which new brewer’s yeast are being created to drive beer flavour and aroma innovations. By applying the classical technique of selective breeding – used for millennia in the domestication of species – it becomes possible to re-imagine brewer’s yeast, thereby enhancing and expanding yeast’s natural ability to define beer styles and flavours.

Controlling yeast | In the first part of this three-part article (BRAUWELT International No. 5, 2018, pp. 354-356), we outlined the enormous impact yeast has on the flavour and aroma profile of beer. In this sec ond part, we discuss the variables and methods by which brewers can exert direct control over yeast during the brewing process. In the concluding article, we will examine the time-honoured, non-GMO classical development techniques by which new and exciting yeasts are being developed to help create whole new flavour and aroma profiles in beer.