Krones | On 12 December 2019, the executive board of the Neutraubling-based company decided on additional structural efficiency measures.

Canning line | When it comes to brewing, the Mack Brewery in Norway has long since been putting its trust in Krones’ technology, most recently for canning as well. This means the Bavarian plant engineering specialist is handling the brewery’s core remit, since cans account for over 90 per cent of total beer sales.

Empty and full container inspection | Returnable glass is in line with the trend! Gerolsteiner Brunnen has reacted to the growing thirst for refreshing drinks out of appropriate individual and GDB (German Mineral Water Association) bottles – with a completely new filling line. Highly automated Heuft equipment for inspecting empty and full containers ensures that Gerolsteiner mineral water is bottled safely and faultlessly there. The TornadoII dynamic labeller carries out the careful decoration of the glass containers for an attractive look at the point of sale.

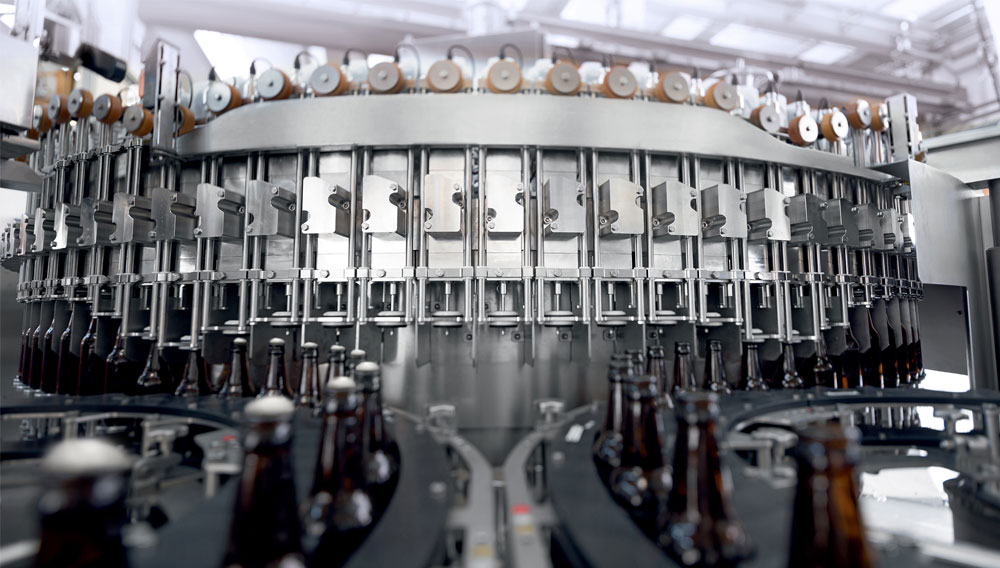

Portfolio addition | The market for glass bottles is estimated to continually thrive over the next few years. This especially holds true for the beer market but also for other categories, such as water, juices and carbonated soft drinks (CSD). To keep abreast of this development and adapt to the ever more rapidly changing market and product trends, manufacturers expect new solutions, which offer high production flexibility, while at the same time guaranteeing maximum quality for their premium products. Sidel, one of the leading providers of equipment and service solutions for packaging beverage, food, home and personal care products, is now answering their call with a new filling system.

Ideas for the future | Industry pioneers such as Lorenz Adalbert Enzinger and Theo Seitz bear witness to the long tradition research and development enjoys at KHS. Like them today’s KHS engineers don’t always go with the flow but pursue many different paths in order to stay at the helm of progress. The article describes how KHS GmbH from Dortmund deals with digitization and other topics of the future and prepares for it.

Success all along the line | Established in 1997 in Grand Rapids, Michigan, Founders Brewing is one of the most well-known and popular craft brewers in the US. They owe their success to their focus on creating quality products rather than just growing their bottom line.

Krones AG | Based on current figures, Krones AG, the Neutraubling-based manufacturer of filling and packaging technology adjusts its earnings forecast for the fiscal year 2019.

Solid-Liquid Separation | Water, hops, yeast and malt – the raw materials used to brew traditional craft beer hardly ever stray from these four ingredients. However, aside from high-quality raw materials, utilising equipment and technology ideally suited for producing these beers also plays a critical role. Of great importance in this respect are certainly the processes of separation and filtration, not only of wort and beer, but also of water, yeast and not least of all the reusable constituents at the end of the production chain.

The Calgary-based inventor of micro-canning equipment for craft brewers has donated a canning system to the growing Beer Industry Program at Metropolitan State University of Denver. Cask’s Micro-Automated Canning Systems (mACS) will serve to educate the program’s students on the packaging, environmental, and freshness-keeping benefits of canned craft beer.

Matching kegs | People are sure to sit up and notice when an old, decommissioned factory, formerly of major regional significance, is converted into a brewery. Ecological sustainability is an added factor when only high-quality products and ingredients from the surrounding area are used for beer production. This reflects the self-perception and corporate identity of Hordeum brewery in Novara, Piedmont, Italy. Regional craft beers are brewed there at a capacity of 1500 hl.

Large-scale project | For years now, a diverse range of beverage products containing alcohol has fueled continuous growth in the segment. “Ready-to-drink” products (RTDs) include beer and cider as well as other beverages containing alcohol mixed with sodas, fruit juices or other non-alcoholic drinks. In South Africa, RTDs are in high demand. The Distell Group is one of Africa’s leading producers of spirits, premium wines, ciders and other RTDs. This case study describes the conversion of the production at the Distell Springs facility from a batch process to an in-line process which is controlled by measurement of the concentration in degrees Brix.