Sidel | Varun Beverages Ltd, Gurgaon, India, part of RJ Corp group, one of the largest franchises for PepsiCo Inc. globally, has installed Sidel’s Aseptic Combi Predis™ in its newly established plant in Punjab, India.

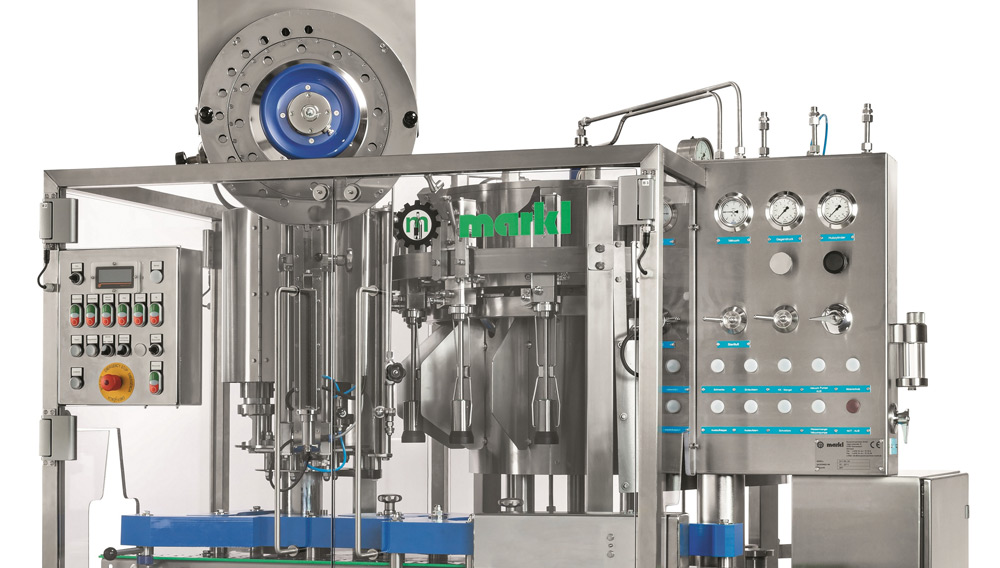

Flexibility | For Carlow Brewing Company GEA Vipoll, Križevci pri Ljutomeru, Slovenia, will install Ireland's first Visitron All-in-one line. Looking for a multifunctional filling system, the craft brewer chose GEA's combined rinser-filler-seamer block, which offers brewers maximum production flexibility and reliability.

RFID Technology | Montelektro, Rijeka, Croatia, a system integrator in the brewing industry, and 8Sigma, Zagreb, Croatia, a MES provider delivered the solution KegTNT (Keg Track&Trace) to a brewery in Addis Ababa, Ethiopia.

KHS Group | The new long-tube filler from KHS provides flexibility regarding the range of products and containers. The maintenance-free drive technology reduces the effort required for cleaning.

Caustic filtration | In recent years Ecolab’s BottleGuard™ has gained a strong position on the market as a comprehensive means of handling hygiene and improving the bottling process.

Barrier technology | The Bundesrat (upper house of German parliament) recently voted in favour of extending the mandatory deposit on containers to cover all non-returnable plastic bottles and beverage cans.

Absorbing disruptions | Filling lines consist of individual pieces of equipment which may be subject to downtime due to disruptions in the process. A number of factors determine how long this downtime lasts.

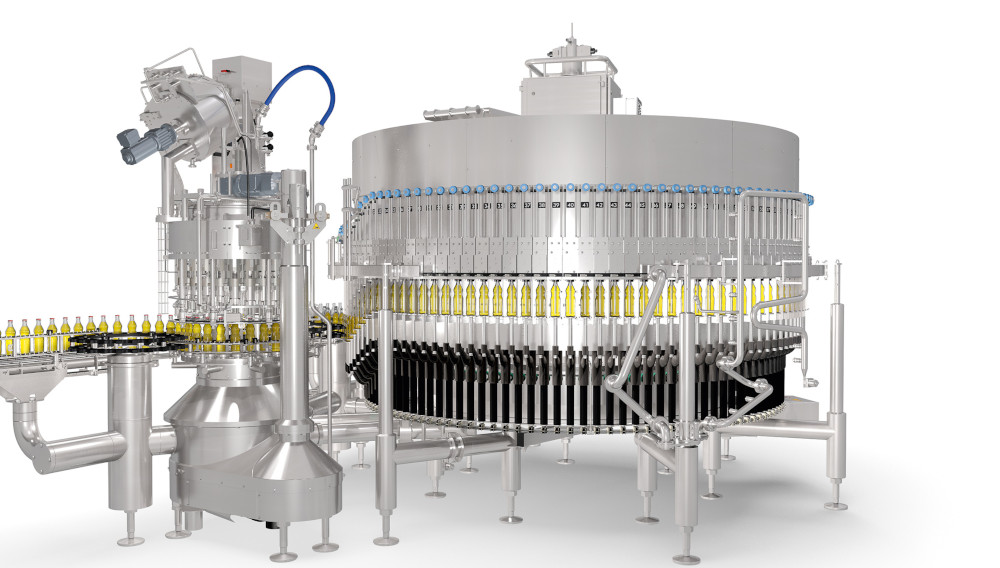

Increased capacity | A growing domestic market and a trend towards premium beer in the UK and the US recently led Birra Peroni, part of Asahi Group Holdings Ltd., to upgrade their glass bottling capacity.

For some time now, in Germany and all over Europe, there has been substantial demand for equipment that can fill both bottles and cans.

Ginger beer | Krones delivers the entire wet end for the first-ever canning line for Bundaberg Brewed Drinks, an Australian family famous for their ginger beer.

Sidel | In 2017, the Sidel Aseptic Combi PredisTM blow fill seal filler was validated by the American Food and Drug Administration (FDA) for low acid products sold in the US – an industry first. With more than 180 references at major beverage and dairy companies since the launch of this safe and simple solution in early 2000, the repeated orders recorded by this technology underline its success.