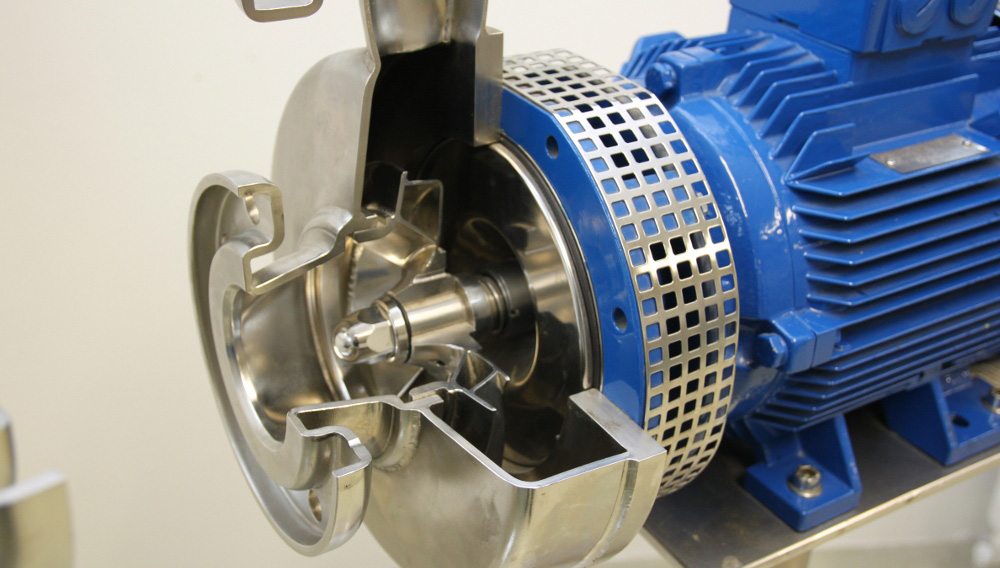

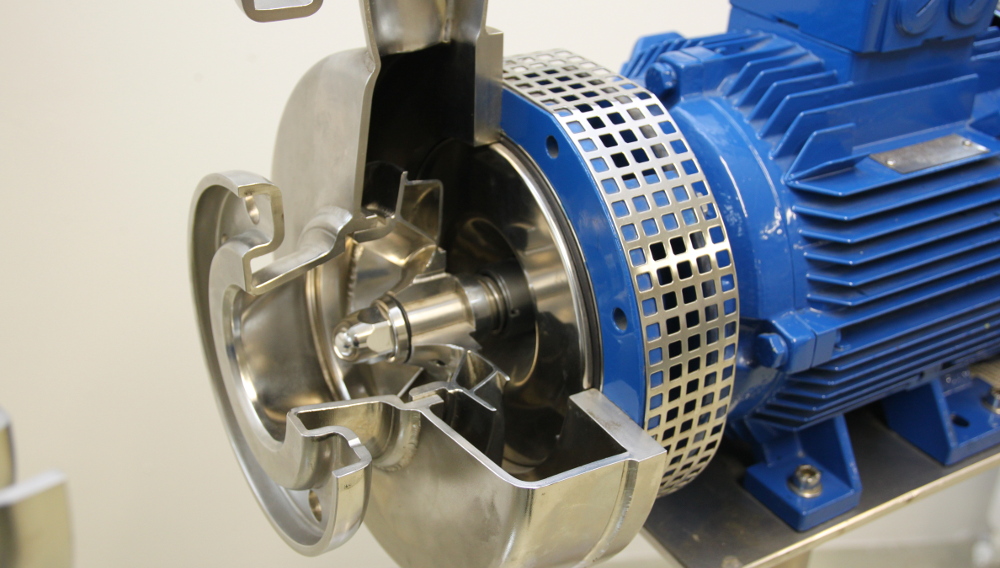

Components of centrifugal pumps | Centrifugal pumps, in particular rotary pumps and side-channel blowers, play a central role in production of beverages. This second part of the series of articles about pumps describes the design of the drive and pump shaft and explains the requirements relating to these types of pumps used in beverage production.

Introduction and designs | Pumps are central elements in breweries and beverage operations, they are workhorses that keep processes running. A multi-part contribution covers the different common designs and criteria for use of pumps. This first part deals with general questions, pump designs and centrifugal pumps.

Developers want feedback | On October 1, 2020, Dr. Mark Schneeberger assumed leadership of Application Development Beverage & Beer at GEA in Kitzingen, Germany. He succeeded Dr. Rudolf Michel, who went into well-deserved retirement at the end of March 2021. BRAUWELT interviewed Dr. Schneeberger about his new position, one year on.

Green hydrogen | A continuously growing number of companies are choosing to reduce their CO2 footprint or even achieve CO2 neutrality. For production companies, including those from the brewing sector, this often raises the question of how to provide process heat in a climate-neutral way. The use of green hydrogen in boiler systems represents a significant opportunity. As well as generating a high boiler efficiency rate of up to 98 %, its combustion is entirely CO2 neutral. The following technical report focuses on solutions using hydrogen boilers and on technical measures for safe, clean hydrogen combustion.

Centrifugal pumps | VLB Berlin has developed new methods for determining whether a pump is conveying fluids in a gentle manner and has thus created a new service that allows centrifugal pumps to be evaluated with regard to their pumping properties. The new method is based upon the formation of β-glucan gel from barley in response to shearing forces. Unlike established methods derived from the field of microfluidics, the pump does not need to be modified. It can be tested in the same condition as it would be supplied to the customer.

Hüll aroma hops | The climate change brings particular challenges for hop growers and brewers. Aurum, the new Hüll aroma variety with a Tettnanger background, presents itself not just as a climate-tolerant noble hops but also with a fine-hoppy aroma in combination with a pleasant subtle bitterness and lives fully up to its name in numerous brewing tests.

Test brews | Yield of hop bitter substances is key to efficient use of hops. However, solubility of α-acids in an aqueous environment strongly depends on pH value and temperature. In this respect, wort does not offer optimal conditions for adequate isomerisation of α-acids. When ionising water, a by-product having an alkaline environment is formed. This is used for isomerisation of hop α-acids and for raising yield of bitter substances.

Comprehensive guide | With the “Beer Brewing Guide – the EBC Quality Handbook for Small Breweries”, published in June 2021, the Brewers of Europe and the European Brewery Convention commissioned a new must-have book that provides small breweries and aspirational professional brewers with practical tips to improve the way they brew on all critical quality points, from receiving the ingredients to ensure their beer is poured the perfect way.

Historic brews | At Colonial Williamsburg, a 1.22-km2 (301-acre) “historic district and living-history museum” [1] in the heart of the small City of Williamsburg in the state of Virginia, history indeed comes alive … literally. As you stroll along painstakingly reconstructed residences, workshops, inns, and taverns dating from the late 18th century, interpreters and actors in period costumes recreate daily life from the time of the American Revolution (1775–1783), when such luminaries as the United States’ first president, George Washington, its third president, Thomas Jefferson, and its fourth president, James Monroe, walked the district’s streets.

Aging behavior | During experimental trials conducted to assess the reproducibility of the 2 hl pilot brewery at Hopfenveredlung St. Johann GmbH, it was determined that a number of hop aroma compounds were transferred from hops to beer. Subsequently, the behavior of these compounds in the finished beer over the course of aging was investigated [1].

Wet milling | The malting and the brewing industries are in a constant need of saving money, energy and lowering their carbon footprint. What if maltsters could skip the most energy consuming step of nowadays malt production, i.e. the kilning process? And what if brewers had a workable process to mill the green malt? This article presents an introduction to brewing with green malt with an innovative wet milling system comprising two sequential mills, the first being used for cutting and the second for crushing.