Analysis methods | A beer is as good as its raw materials. Control using various analysis methods is required to ensure that malting barley and malt are of the highest quality. This article give an overview on how analysis developed from the first specifications of malt to up-to-date technical solutions.

From hops to beer | The choice of the hop variety is one of the key factors that determines the final aroma of beer. During beer production, hop volatile compounds are chemically and biologically transformed to form new compounds that are not significantly present in the hop cones. To understand the complexity of these modifications and their influences on the final beer aroma, 14 hop varieties were compared for their ability to apport aroma compounds to the beer.

A towering achievement | A malting facility known as “Maltaria Campos Gerais (MCG)” is currently under construction in Brazil, and it is certainly raising the bar for malt production. Once completed, it will boast a nominal annual production capacity of 240 000 t. The plant is slated to be commissioned at the beginning of the fourth quarter of 2023, after just under two years of planning and construction.

Hop aging | When hops age, chemical changes occur that reduce their brewing value. As long as the hop cone is on the hop bine growing in the field, no oxidation happens. As soon as the hop plant is harvested, the clock starts ticking before hops are packaged. The enemies of hops are high storage temperatures and time, as well as whether they are stored in oxidative or non-oxidative conditions. In this first part of an article series we discuss what this means for the brewer, introduce the Hop Storage Index and talk about the economic implications of hop aging.

Enhancing flavour | Significant levels of geranic acid were found only in the test beer brewed with Sorachi Ace hops. This beer was brewed originally in 1984 by Sapporo Breweries Ltd. It could recently be determined that this compound has very unique characteristics, it is less odor-active but functions as an enhancer for other hop-derived flavor compounds. The following article summarises a part of the research results which have already been published in BrewingScience, 2022, issue 6: November/December.

Withering and kilning | Depending on processes and equipment, not every malt grain experiences the same conditions during malting. Measurable differences in malt quality between the various floor layers are thus inevitable. This study investigates the extent to which these inhomogeneities also have repercussions for gelatinisation temperature of the resulting malt.

Amino acids in malt | Availability of assimilable nitrogen supply is usually determined by measuring free amino nitrogen (FAN) in malt. However, amino acid composition in the resulting wort may vary substantially between barley varieties, hence impacting on yeast fermentation and beer flavor profile and stability through Strecker degradation. For optimization, and in particular when susceptible beer styles are involved, a balance of amino acid levels and composition in malt is therefore the subject of research.

Pilot-scale study | Dry hopping is applied to produce many different beer styles with varying alcohol contents. Information about the alcohol-dependent behaviour of hop components after dosing is necessary to understand interactions and to ensure consistent beer quality. A pilot-scale study was therefore performed using standardised procedures by only varying the beer’s alcohol contents from 0.5 % to 10.5 % alcohol by volume (ABV) at constant dry hopping rate.

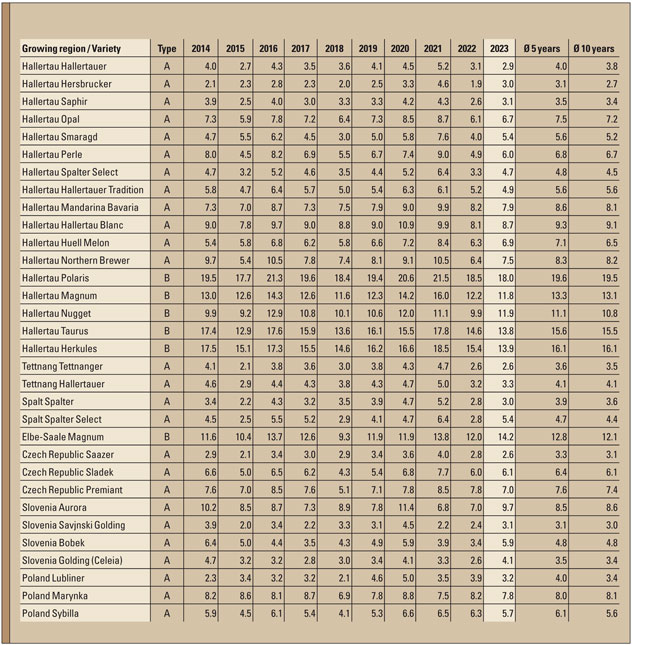

Latest BarthHaas Report | It is always eagerly awaited, and on 25 July 2023 the time had come again: as part of an online press conference, hop trader BarthHaas from Nuremberg presented its report 2022/2023 with the latest figures on the world hop and world beer market.

Europe | The weather conditions in spring 2023 are expected to lead to quite heterogeneous spring barley harvest results in Europe, with weak and very heterogeneous screening, cause by drought in many regions of Europe this spring. Weak protein values also characterize the first batches.

IHGC in Ljubljana | This year’s hop meeting from June 25 to 29 in Ljubljana broke all previous records: with over 80 participants from 15 countries, 36 talks and 20 posters, it was the best-attended event staged by the Scientific-Technical Commission of the International Hop Growers’ Convention (IHGC).