Genetic test | Some contaminant yeasts make beer bottles and cans explode. Apart from being dangerous for consumers these ‘diastatic’ yeasts also cause loss of beer batches due to off-flavours, increased alcohol and over-carbonation in products. VTT scientists developed a genetic test for brewers to detect the strains that cause these problems.

Pilot tests | Part 1 of this contribution (see BRAUWELT International No. 2, 2019, pp. 144-147) reported about tests with mash and wort on a laboratory scale in which precipitation of prooxidative iron ions using hop α-acids in the form of CO2 extract additions was investigated. Part 2 deals with optimised hopping in order to trigger systematic precipitation of hop irons during brewing and thus extend the shelf life of beer.

Unprecedented possibilities | The term “sensory evaluation” covers a wide range of meanings. Physicists describe it as a field of measuring and control technology using sensors. When associating sensory evaluation with living beings, it broadly refers to the reception of external and internal stimuli. In the food industry and particularly in the beverage and brewing sector, it is understood as referring to analysis carried out by human sensory organs.

Rigorous Monitoring | Currently, an estimated 7.5 billion people live on Earth. If all of them were the size of microbes, they would all easily fit in a large cup of yogurt. Thus, a hairline crack (in tanks, piping or seals) with a length of 3 mm and a depth of 0.03 mm provides sufficient space for around 100 000 microorganisms. Sometimes visual comparisons are useful to put hygienic requirements in production in the proper perspective.

Rapid analysis | CellFacts II, a rapid microbiological detection system, provides an “eye in the process of brewing”. Using a combination of electrical impedance and fluorescence technology, the instrument can be used for the rapid detection of colloidal protein, yeast and bacteria. The technology has applications across the whole of the brewing process from start to finish, including the real time assessment of the health and vitality of pitching yeast.

Solid-Liquid Separation | Water, hops, yeast and malt – the raw materials used to brew traditional craft beer hardly ever stray from these four ingredients. However, aside from high-quality raw materials, utilising equipment and technology ideally suited for producing these beers also plays a critical role. Of great importance in this respect are certainly the processes of separation and filtration, not only of wort and beer, but also of water, yeast and not least of all the reusable constituents at the end of the production chain.

A common goal | Those, who have worked in a medium-sized or large brewery may have made the experience that cooperation between chemists, microbiologists or technicians from the quality assurance departments, in short called “QA”, and master brewers, process managers and packaging line managers, in short called “master brewers”, could be more efficient and built on trust. This series of articles aims at fostering an interest in and an understanding of one another because QA and brew masters have a common goal.

TPO calculation | The specific measurement of dissolved oxygen (DO) in beverages is a well-known, frequently used, and straightforward analytical procedure which yields highly precise results. However, sometimes it is not enough to know how much oxygen is dissolved in the beverage as also the oxygen in the head space may affect the product. Therefore, head space oxygen needs to be considered as well.

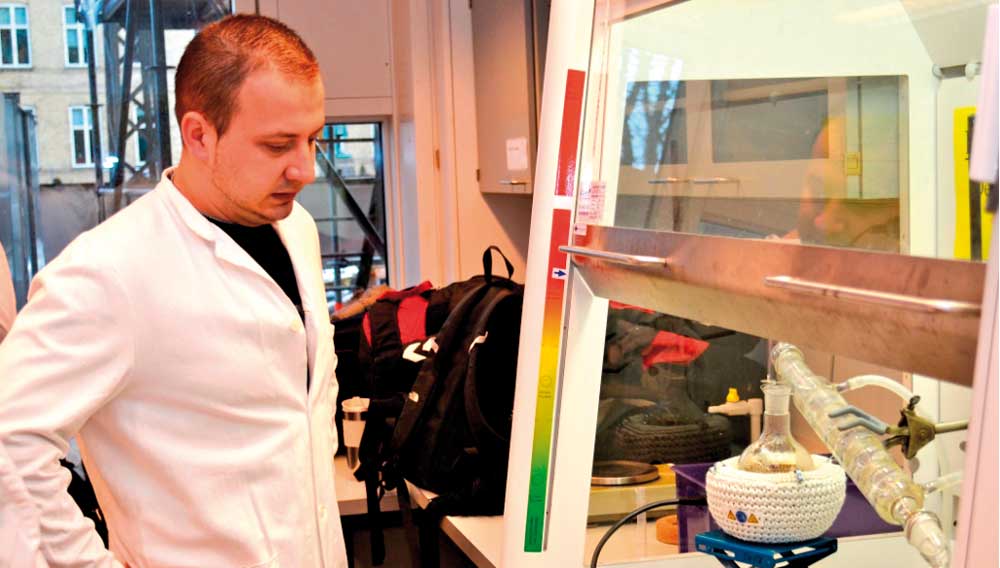

Reliable instrument | Consumers like beer that is not subject to quality and taste fluctuations and brewers are working to come up to their expectations. The following article explains how the latest measurement technology helps increase visibility into the fermentation process, thus contributing to constant quality.

Important collaboration | In Part 4 of this series of articles (BRAUWELT International No. 6, 2018, pp. 437-439), examples of how a master brewer can use and interpret early warnings from the QA department in a brewery were presented, all the way through from raw materials to the final beer. Doing this rapidly makes faster corrections possible and reduces cost.

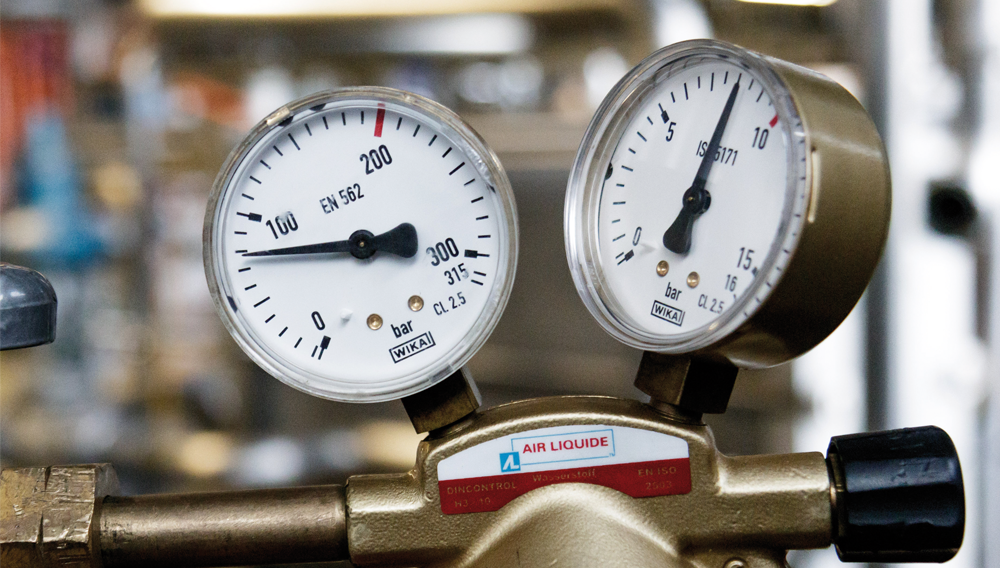

Maintenance | The Oettinger brewery prevents unplanned standstills of their heat exchangers by annual leakage tests. The company prefers test gas for their tests, thus preventing the operational procedure from being affected.