Beer color equations | This is the second article in a three-part series about the challenges of specifying beer color at the recipe design stage, as well as measuring it after the beer has been brewed. It examines the most common equations currently in use by brewers around the world for specifying beer color before the brewing process begins.

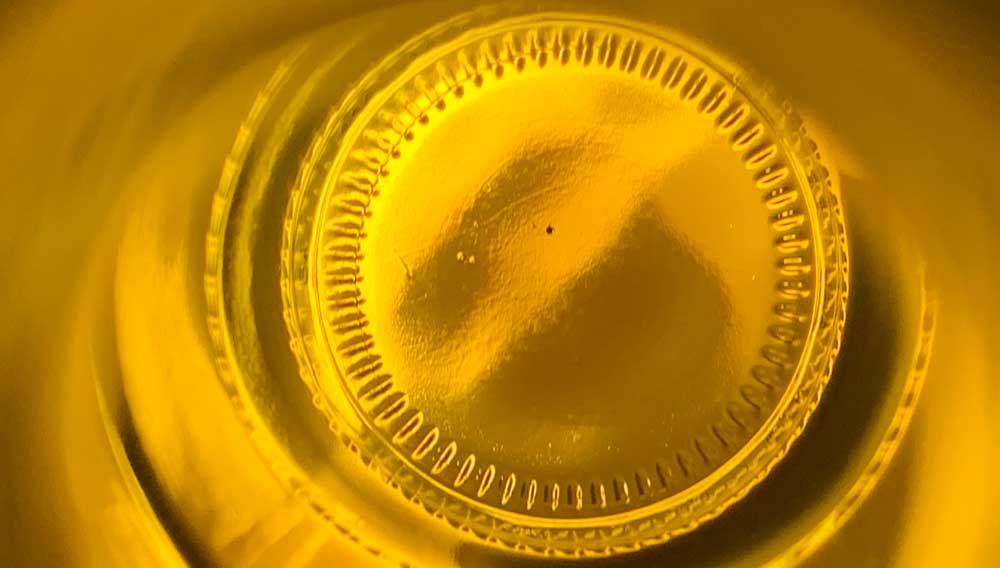

Inspection of empties | Regular verification of cleaning performance of bottle washers in breweries is important in order to ensure perfect product quality and product safety. This is the reason why the Research Center Weihenstephan for Brewing and Food Quality, Freising, Germany, in cooperation with five breweries, validated a test series with standardised contaminated bottles. This should enable breweries to carry out their own checks.

Measuring beer color | This is the first in a three-part series of articles about the nature of beer color, as well as the difficulty of accurately quantifying color both at the recipe design stage and in the finished beer. Part 1 explores the nature of color in general and the historical evolution of beer color measurements. Part 2 examines the differences and similarities of the most common equations used by today’s brewers around the world for calculating beer color – not after the fact in the laboratory – but in advance during recipe formulation. Finally, part 3 analyzes three test beers brewed specifically for this study. It compares the color predictions for these brews made by the different beer color formulae outlined in part 2 to the actual color measurements of the same brews made in the laboratory. This comparison allows practical brewers to select which equation might be the most advantageous for them to use at the recipe design stage.

Feel the process | The packaging of products is something that, apart from the beer itself, speaks to the consumers. Packaging is present in all parts of the production process, involves the majority of plant departments, and runs through all stages of the supply chain. Therefore, understanding what our bottles and cans experience, or in human words: what they “feel” in the process, turns out to be crucial to the brewing businesses and – as various real-life cases show – leads to wonderful benefits. Especially, when the “feeling” is translated to data.

Ageing behaviour | Forced ageing at 40 °C is one of the most common methods for assessing sensory stability of pale lager beers. However, different aroma profiles frequently arise in practice compared to natural ageing at 20 °C. The present article describes the ageing characteristics of pale lager beers during forced and natural ageing, both in sensory and in analytical terms. The contribution is based on research results that have been published in BrewingScience, May/June 2018, volume 71.

Haze-active proteins | Although mostly avoided, uniform beer haziness is the main visual attribute for specific beer styles, such as wheat beers (e.g. Belgian Wit, German Weizen etc.) and hazy IPAs.

Barrier technology | The Bundesrat (upper house of German parliament) recently voted in favour of extending the mandatory deposit on containers to cover all non-returnable plastic bottles and beverage cans.

The European Brewery Convention has updated two of its methods: method 4.14 “Modification and Homogeneity of Malt: Calcofluor Method” and method 6.5 “Extract Content of Maize: Enzymatic Method”.

Quality control | Beverage producers aim to manufacture products of consistent quality that meet specifications. The prerequisite for this is a comprehensive quality analysis, not only during production, but also on the finished product. Quality control also includes the carbon dioxide content as it significantly contributes to the taste experience.

Brewing economics | A sustainable future for brewing: obiviously, everybody is for it – but how do you actually evaluate and implement sustainable brewing practices and procedures that not only resonate with consumers but also make sound business sense, both in the boardroom and in the brewery?

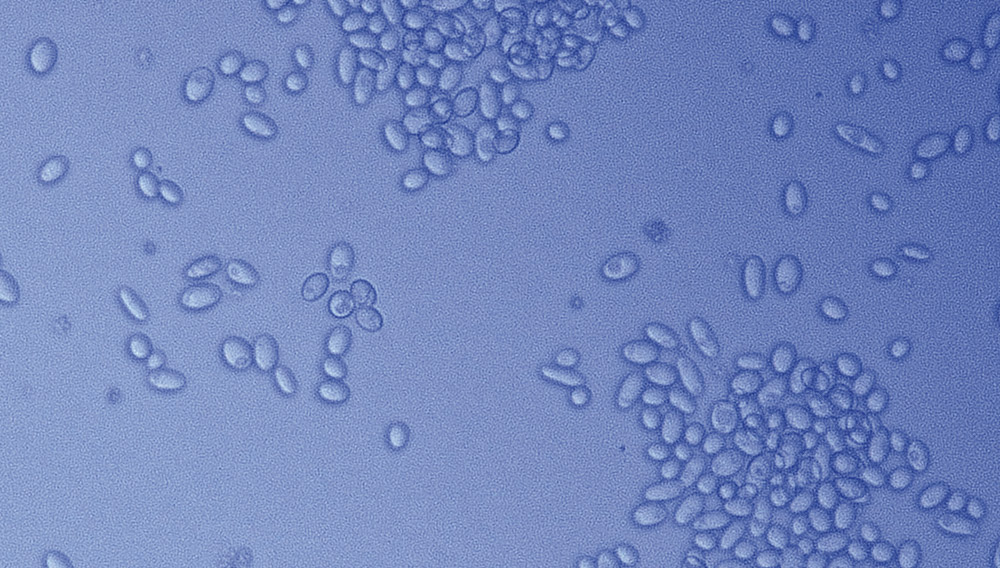

Over-attenuating yeast | At the turn of the century, hardly anyone in Germany was familiar with this yeast. Nowadays, Saccharomyces diastaticus has virtually become a household name, especially among craft brewers. Some use it to brew novel beers in the style of those from Belgium. Others, however, fear this yeast and despise it as a beer spoiler, conducting extensive analyses to detect the merest traces of its presence in an effort to eradicate it in their breweries.