Test results | Rapid and reliable detection of beer spoilers is still a frequently discussed topic in brewery microbiology that has not yet been resolved to-date. In the context of a bachelor thesis, a study for using the so-called impedance method was presented. Extracts of same are reported in this article.

Hop aging | When hops age, chemical changes occur that reduce their brewing value. As long as the hop cone is on the hop bine growing in the field, no oxidation happens. As soon as the hop plant is harvested, the clock starts ticking before hops are packaged. The enemies of hops are high storage temperatures and time, as well as whether they are stored in oxidative or non-oxidative conditions. In this first part of an article series we discuss what this means for the brewer, introduce the Hop Storage Index and talk about the economic implications of hop aging.

Withering and kilning | Depending on processes and equipment, not every malt grain experiences the same conditions during malting. Measurable differences in malt quality between the various floor layers are thus inevitable. This study investigates the extent to which these inhomogeneities also have repercussions for gelatinisation temperature of the resulting malt.

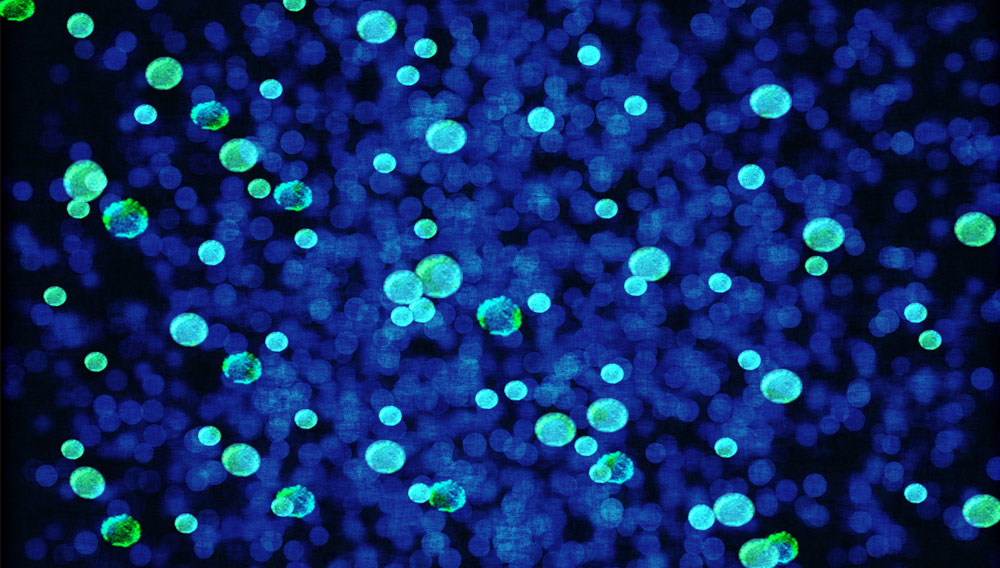

Real-time monitoring | From Austria comes an interesting new technology that will permanently change the water treatment processes in the beverage industry and make them more efficient: the ColiMinder, an on-line instrument for fully automatic monitoring of microbiological water quality in the beverage industry.

Standardization | Quality and product safety are at the heart of the core demands of consumers. For this reason, most breweries have developed and now routinely implement comprehensive quality assurance measures as an essential part of their product analysis. Today, breweries document the product quality attained by applying these measures in detail through meeting predetermined specifications and issuing certificates of analysis, the continuity of which are reliably checked on a regular basis using standard procedures. Among the tools available to breweries is sensory analysis, a field that is becoming increasingly important in this context.

Beer ageing | During the malting process, malt modification is influenced by targeted adjustment of germination parameters (technological factors). The level of precursors in the malt, formed during malting, makes a significant contribution to beer ageing. This article describes, in particular, the precursor potential, formed from non-enzymatic degradation of polysaccharides.

Brewery hygiene | If we look back on 50 years of brewing microbiology, we gain a number of extremely interesting insights. Can we draw a positive conclusion here or are there also negative aspects that have to be taken into account?

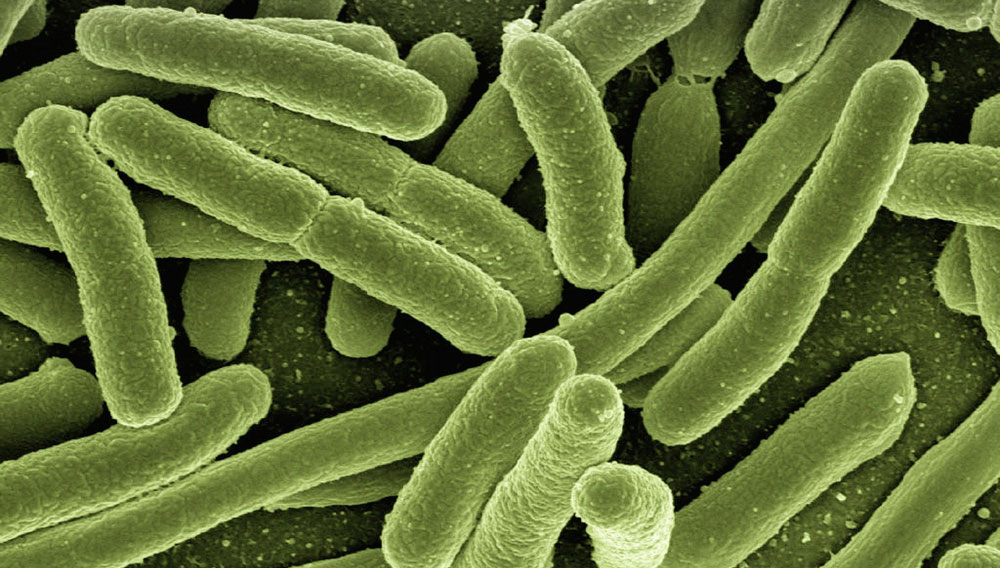

Beer-spoilage potential | In the food industry, lactic acid bacteria play a special role, they have become important both as beneficials and as spoilers. Lactic acid bacteria also have these two opposite characteristics in breweries.

Practical findings | Beer loss has always been one of the biggest challenges to breweries with regard to efficient beer production and maximisation of the beer sold. Especially when making hoppy craft beers, where dry hopping is often practiced, the beer yield is drastically reduced. Thanks to the latest practical findings from a long-term BrauKon trial, the amount of beer loss can now be significantly reduced by adjusting two characteristics in the cylindroconical vessel: essential here are a special surface finish and a defined cone angle.

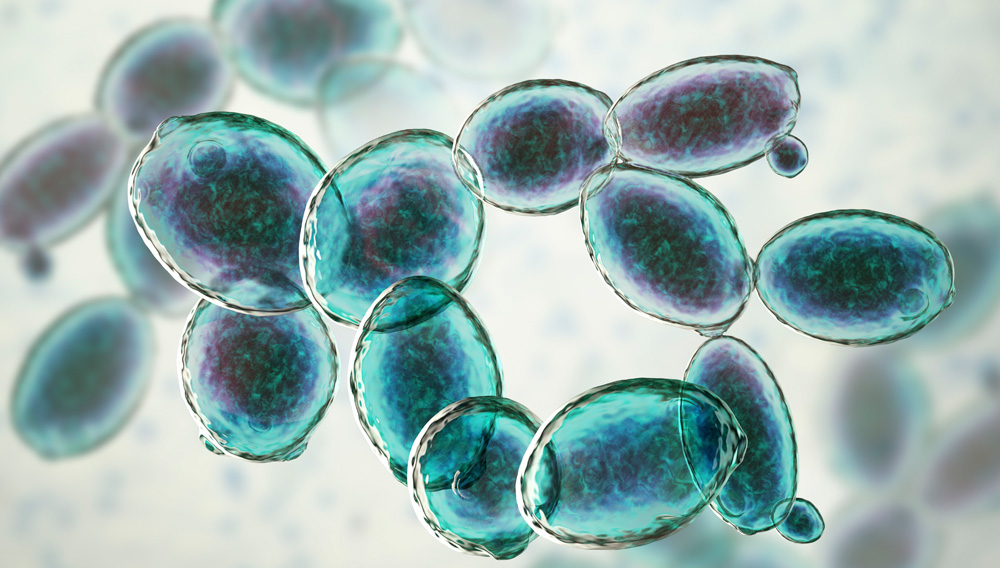

Vibrating sieve | Beck’s – the name is legend and the advertising campaign featuring the Alexander von Humboldt barque with its green sails cutting through the waves to “Sail away” familiar to many of us since 40 years. GEA project engineer Clemens Fries claims that this is “an inspiring environment in which to perform ‘minor open-heart surgery’.” Fries is namely responsible for the new special yeast sifting plant that’s now been integrated in Bremen as a fully-automatic process line.

Trained senses | Is a sensory panel suitable as an “analysis instrument” for monitoring the quality of spirits? Can training a panel specifically for detecting wood-derived substances, key aroma substances, color and faults common in whiskey supplement, or even replace, laboratory analysis for measuring individual substances? Are there limits, and if so, what are they? This is the third installment in the series, which began with the basics of barrel aging in part 1 and continued with the laboratory analysis of barrel-aged spirits in part 2 [1, 2]. In this installment, the authors will consider another measuring device: human beings.