A multi-causal problem | The spontaneous overfoaming of beer or carbonated beverages after opening the bottle without any external mechanical influence such as shaking is known as “gushing”. The product return or recall actions this triggers can lead to high financial losses – and can damage a company’s image. The causes of gushing – a multi-causal problem – are still not fully understood, although much research on this subject has been carried out over the years. It is known that gushing can be caused by raw materials on the one hand (primary gushing) and by technological factors in production on the other (secondary gushing). This article presents the research results on the influence of water quality on gushing behaviour in the Modified Carlsberg Test.

Brewed to perfection | For most consumers, it would seem logical that beer could simply be brewed by following a recipe. However, a glance at the typical characteristics of a Helles-style beer reveals very narrow limits on the variability regarding original gravity, bittering units, color and aroma. Similarly, the possibilities for creativity in recipe design also appear somewhat limited. Yet this is precisely what makes this beer style so fascinating, the quality of which is largely determined by the brewing technology – or rather the art of brewing.

Food safety | Implementation of hygienic design in the beverage sector provides many benefits. When cooperating with engineers, designers and experts for food safety, companies can assure that their production facilities comply with the strictest hygiene standards and maintain quality and safety of their products.

Cleaning efficiency | Modern CIP systems are only a point of discussion when they don’t work as they should do. CIP systems provide great service for a long time without any grounds for complaint or the need for any further intervention – bar the necessary maintenance. Their degree of efficiency can decrease, however. More detailed study of CIP systems reveals that they do indeed have several weak points that can mutate into risks.

Coordination | Outstanding beer quality is of paramount importance for a brewery. The implementation of strict quality management systems ensures that beer is within the required specification at all stages of production. This is challenging enough for a single brewery, but it becomes exciting when several brewery sites are operated and quality managed simultaneously.

Hop Storage Index | When evaluating hop quality, many use the Hop Storage Index (HSI) as a simple analysis to get an indication of how much the hop has been aged. The rule of thumb is: the higher the HSI, the poorer the hop variety was harvested, stored, and processed. Although HSI can be a useful tool, it is important to understand that the value should not be the sole indicator to understand the total hop quality.

Underestimated risk | Mould fungi are part of the natural microbial flora of malting cereals. In recent decades, intensive research focussed on the fungus genus Fusarium plant pathogen in this respect. However, the consequences of contamination with the so-called sooty mould fungi are hardly known in comparison.

Cleaning results validated | Spray shadow tests are a useful and proven tool for validation of automatic cleaning systems. This holds true for new installations, changes to existing systems and regular revision. Based on two industrial examples, the usefulness of two different spray shadow tests, both used at VLB, is illustrated.

Optimised cleaning | On-demand cleaning is today often seen as a vision for a new form of sanitation. But what’s behind this? How is the need for cleaning defined? Martin Löhrke, CEO of Jürgen Löhrke GmbH in Lübeck, Germany, takes a look at the options already in place to meet the requirements of individual cleaning operations.

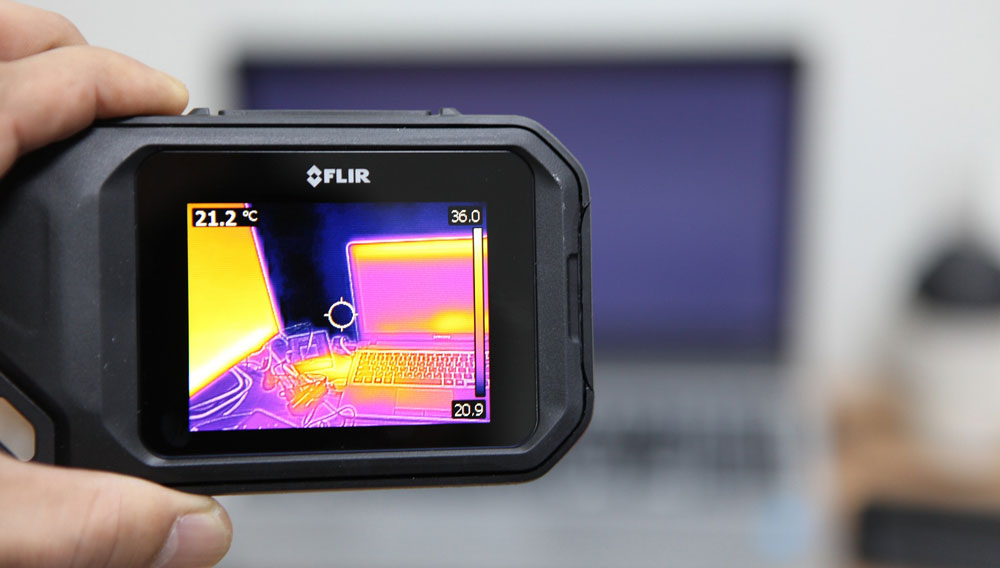

Analysis methods | A beer is as good as its raw materials. Control using various analysis methods is required to ensure that malting barley and malt are of the highest quality. This article give an overview on how analysis developed from the first specifications of malt to up-to-date technical solutions.

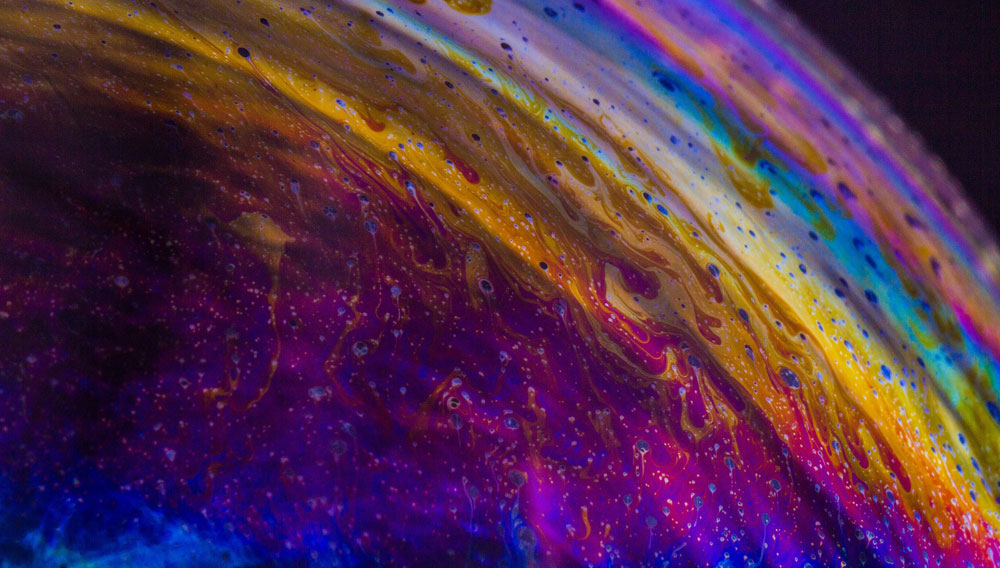

Inline analysis | Spectroscopic methods offer the option of real-time analysis and, thus, optimisation of conventional methods of food processing. Chemical reactions triggered by thermal exposure can be tracked, based on the knowledge of reaction kinetics for quantification of thermal input. This has the potential for more product-specific process control, in this case in pasteurisation of apple juice.