Membrane technology | Alfa Laval, a world leader in heat transfer, centrifugal separation and fluid handling, has acquired Sandymount, a US-based beverage technology company with a unique and patented membrane technology to concentrate beer. The signing and closing date was December 31.

Dealcoholization | In August of 2019, “Ghost Ship 0.5 %”, a pale ale with strong citrus notes brewed by the British brewery Adnams in Southwold, UK, sailed back to the island nation with the gold medal it earned at the World Beer Awards. The award rounded off a year of meticulous product development with the new GEA AromaPlus dealcoholization system.

Parker Hannifin | Brewers are being given the opportunity to trial innovative sterile filtration technology. Parker Bioscience Filtration , Bielefeld, Germany, has introduced free trial capsules for its Bevpor BR range of filters, enabling breweries to undertake taste and visual quality trials, and test the effectiveness of this filtration method.

Clear enjoyment | Who would not enjoy a clear, cool beer? The authors hope that everyone can continue to simply enjoy it so they focused their research on an approach for monitoring and quality control in beer production based on optical scattering methods, with the aim of developing a simple and flexible measurement instrument for in-line monitoring. The instrument presented could be installed directly in product plants or vessels and used for checking CIP procedures.

Fibres and perlites | The efforts to establish alternative filtering aids in precoating filtration have already extended over several decades. With its approach involving compressible filtering aids, Krones AG, Germany, has now successfully completed an upscaling project in the Schussenrieder Brewery.

Malt quality | Against a background of increasing process automation and ever more stringent requirements for product quality, processing of raw materials with fluctuating properties depending on year and location is becoming more of an issue. With this in mind, the focus on process optimisation is, in particular, on bottleneck process steps such as lautering and beer filtration. Apart from improving process technology, raw materials, in particular malt quality, provide enormous potential for improvement.

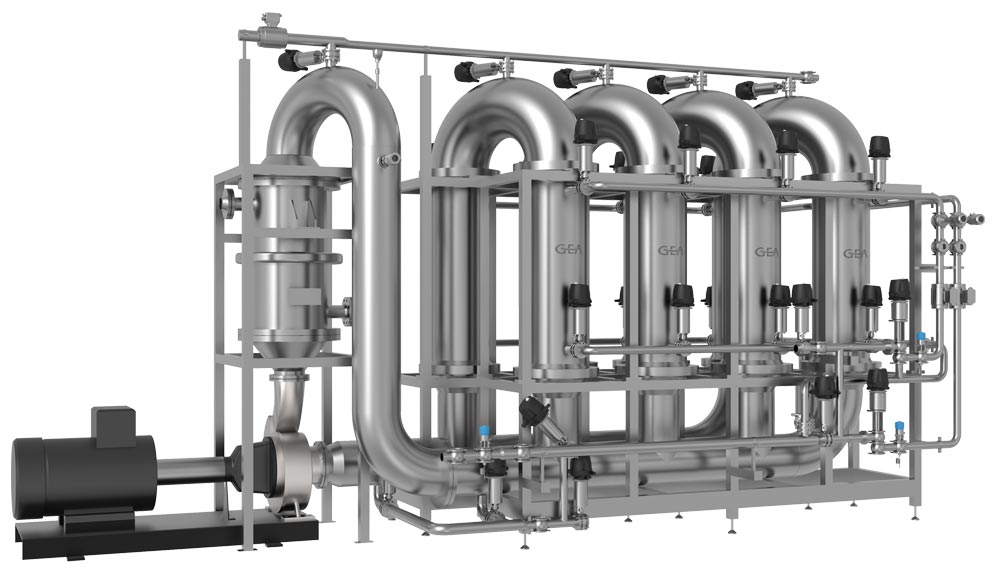

Waste-free | Filtering beer without any waste, and making processes efficient and environmentally friendly is no longer merely a brewing fantasy. Cross-flow filtration with ceramic membranes has what it takes to knock established competitive processes that use kieselguhr or polymer membrane off the throne. However, according to filtration experts Sonja von Lieres and Felix Ockert from GEA Group, Germany, other parts of the brewing process must also be rethought in general.

Clear | Some years ago, bright beers with excellent haze stability were the norm primarily among the larger breweries. However, the consumer also expects the same today from mid-sized breweries. This article discusses why polyphenol stabilisation using polyvinylpolypyrrolidone (PVPP) is an effective solution for this purpose.

All clear? | Raible proposed in 1983 that silica sol could be used to improve filtration of beer [1]. It is in conformity with the Purity Law and can be added in the brewhouse, in the storage tank or immediately ahead of the filter. However, there is no easy rule for predicting the success of adding silica sol. Appropriate laboratory filtration tests can indicate when use of silica sol would be particularly advantageous.

New method | ß-glucans have a negative effect on filterability, haze and lautering but also a positive physiological aspect as well as a positive effect on beer foam. Though high molecular weight (>100 kDa) fractions are primarily held responsible for the negative aspects, it has not yet been possible to describe the fraction responsible for influencing beer foam.

Clearly a good idea | Wort and subsequent beer clarity is still of importance to the brewer and beer consumer. Even for beer styles and brands where a certain level of haze is accepted or even expected, understanding and control over the process is critical for the brewer. The use of carrageenan-based kettle finings historically referred to as copper finings is practically ubiquitous for brewers in the UK and most of the USA. However, in the rest of Europe the use is much more mixed. The manufacture and use of kettle finings are discussed in this article to explore if some brewers are missing out.