The heavy demand at drinktec 2009 in Munich and the results of the subsequent market analysis prompted GEA Brewery Systems to develop this innovative concept. The analysis of the brewing behaviour and the brewing capacity of medium-sized breweries resulted in the demand for brewing plants for quantities between 40 and 100 hl. Building large brewhouses smaller was not the issue.

Washing returnable bottles is of great importance for a brewery, and therefore every brewery should strive to gather the knowledge necessary for the most suitable configuration for its bottle washer. The determining factors are operating efficiency and environmental impact, as bottle washing is a very cost-intensive process, which utilizes a large amount of resources. Additionally, the returned bottles must exhibit a certain level of cleanliness to facilitate their continued use. But how can the success of a bottle washing procedure be measured and evaluated? How effective is it?

This series of contributions will identify the reasons for inadequate yield of bitter substances. The various mechanisms that come into play, necessary for transferring bitter substances from hops to finished beer, are discussed item by item. In part 1, the extraction process step was described in detail (BRAUWELT International 2 2010, pp. 92 - 95). The second part deals with dissolution and isomerisation of bitter substances. The last part describes new equipment designed on the basis of the findings. Such equipment can significantly increase bitter substance yield in beer brewing so that consumption of hops can be considerably reduced.

Australia currently ranks sixth among the world’s largest wine producers. Per-capita consumption is rising continuously, and Australian wine exports are going up significantly. More than 70 percent of the harvest is exported, mainly to the US and the UK, but also increasingly to non-English speaking countries. Some of the wine remaining on the Australian continent is packaged in bag-inboxes as “cask wine”, but many award-winning wines are also filled in glass bottles “down under”. The Rathbone Wine Group, headquartered in Melbourne, has installed a new bottling line, with the complete dry section including the control system supplied from Germany by Ziemann-BMS Maschinenfabrik.

Free dimethyl sulfide (DMS) can produce an aroma in finished beer, which is reminiscent of cooked vegetables. DMS splits off from S-methylmethionine (DMS-P) above approximately 70 °C and is therefore present throughout all thermal handling steps in the production of malt and wort. In this article, the thermokinetic conditions under which S-methylmethionine decays will be described by means of an example involving a reduction in the duration of the wort boiling process for purposes of time and energy saving measures. The decay of DMS-P over the course of thermal brewing processes is examined and defined by Zürcher et al. as a reaction of the first order. A number of experimental trials were carried out, which made quantifying DMS-P degradation during thermal brewing processes possible. Additionally, for a defined period during boiling, the wort was not heated, reducing the total evaporation from eight to approximately five percent.

Like the first part of the series (published in BRAUWELT International No. 1, 2010, pp. 22 - 25) this article does not describe the design of CIP plants and the usage of cleaning agents in all details, but tries to identify – or rather:

Without cleaning, a proper brewing process is not possible. Each plant operator is entitled to expect best CIP results in order to meet the high quality standards for the beer production without any interference of the brewhouse efficiency. Tidiness and hygiene are mandatory and primary focused after the CIP process. If everything is done correctly, the results are good and there is no cause for concerns. But that is not the rule from the authors’ point of view. The following article does not describe the design of CIP plants and the usage of cleaning agents in all details, but tries to identify – or rather: reveal – technical and technological sources of error with appropriate criticism.

This second part provides an overview of the basics of aroma substances boil-off during wort preparation as an example of a food production process (Part 1 in BRAUWELT International No. VI 2009, p. 346 ff.). The differences between the processes evaporation due to boiling and evaporation due to vaporisation are explained. The process basics are then compared to and confirmed by a selection of results hitherto obtained.

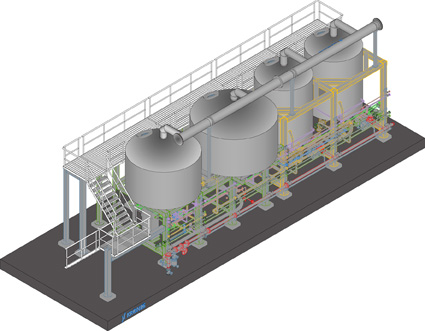

Compact-sized frame-based construction, plus standardised vessels for the mashing, lautering and wort-boiling processes, are the salient features of the latest innovation from Steinecker: the compactly dimensioned CombiCube B brewhouse for an annual production output of up to 150,000 hl.

An increasing number of companies in the beverage industry is prepared to install innovative and environmentally compatible processes for disinfection. One of the main reasons is the bio beverage boom as bio beverages have to be produced under defined conditions. This change and this awareness in the industry open up numerous possibilities for the process of electrolysis. This process has been mentioned oftentimes and has been much discussed but it still raises questions. This article provides an overview of the various processes commercially available and the extent to which they differ.

Liquid food intermediate and end products are subjected to high temperatures and pressures in many processes and production steps in the life science industry. These oftentimes include boil-off processes, all of which – either intentional or tolerated as a side effect – represent a thermodynamic separation process. These processes are of major significance in terms of influencing the content of desirable and, in particular, undesirable aroma substances. This two-part article provides an overview of the basics of aroma substances boil-off during wort preparation as an example of a food production process. The differences between the processes evaporation due to boiling and evaporation due to vaporisation are explained in addition. The process basics are then compared to and confirmed by a selection of results hitherto obtained.