Petainer, after its recent successful Husky installation is to invest further millions into new injection moulding plant and machinery to boost its production capacities within the Group’s Lidköping site.

The installed Husky HPP-equipment is also supposed to contribute to a more ecological production.

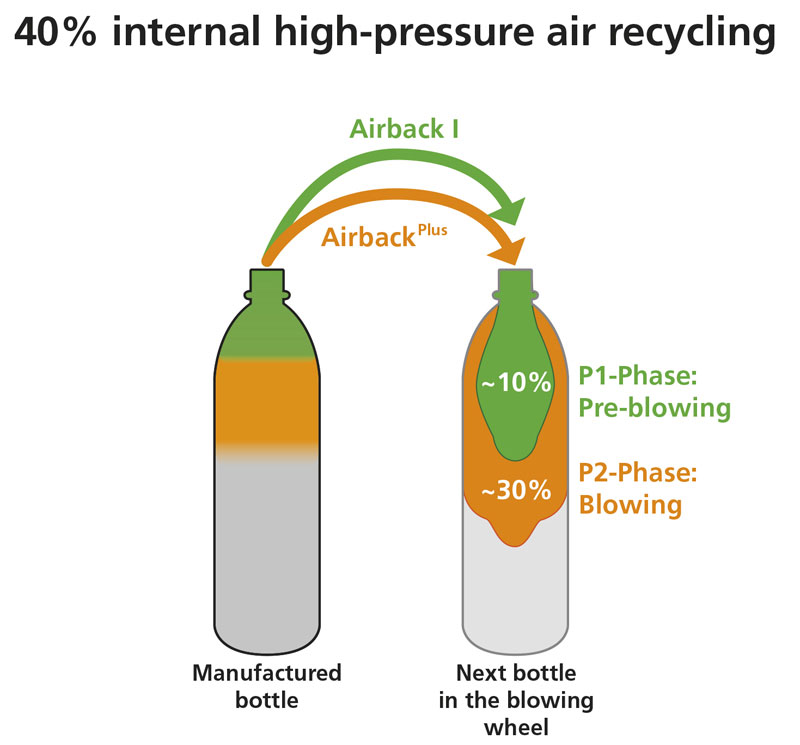

With the help of the newly developed Airback Plus technology by KHS Corpoplast, up to 40 percent of the compressed air used in the stretch blow molding process can now be directly ‘recycled’ in the blowing wheel.

Because simple should be precisely that, there is a foolproof system to aid breweries and filling plants in identifying their kegs. With various types of transponders, custom mounting systems and easy to use data collection software, RFID can be rapidly implemented and is designed for long-term usage, resulting in substantial savings.

A high-quality bottling machine which is hygienically designed, easy to operate and service, extremely flexible, compact, and robust with a long service life: this is just what small and medium-sized breweries and soft drinks manufacturers want when they invest in new filling technology. And this is exactly what KHS can offer them with the Innofill Glass Micro. Plants that invest in this innovation profit from KHS’ extensive knowledge of high-performance filling technology, among other things, and in conjunction with this from tried-and-tested, low-oxygen filling techniques and proven components which are now being used in fillers in the low to medium capacity range.

MyFeelBack has signed a global distribution agreement with the Ceisa Packaging Group, a European manufacturer of plastic packaging. Client companies will now have access to connected and interactive packaging.

In recent years definite changes have taken place in the international beer market. Breweries have tried to expand their outlets and to exploit new markets, which leads to expanded routes of transportation and massively shorter circulation rates of empties. This has a huge impact especially on the sector of draft beer. The following article shows the importance one way kegs have in this context.

With the patented Innokeg Till One4Two treatment head, the brewer Heineken uses a KHS development which, when properly integrated into the keg washing and racking heads, allows the processing of two different fitting types. This had not been possible in the past: A company with kegs with different fitting types in its range always had to replace the centering cone and fitting plunger in both the washing heads and the filling heads, when it changed from processing kegs with basket fittings to kegs with flat fittings or vice versa – a laborious activity which was very time-consuming and required subsequent CIP cleaning. Heineken has used the KHS Innokeg Till One4Two system at its Volga Brewery in the Russian city of Nizhny Novgorod for the first time.

KHS has optimized its Innopack Kisters Basic packaging machine. Identical servo motors with integrated servo controllers are now used for all function units. This reduces and facilitates spare part stockkeeping considerably.

In only 50 years, South Korea has transformed itself from an agrarian society into one of the world’s major industrialized nations. This high growth rate places it in the ranks of the East Asian tiger economies, beside Taiwan, Singapore and Hong Kong. Per capita gross income in South Korea is currently around 19 000 USD (13 365 EUR; 1960: 100 USD). Naturally, this torrid pace of development has resulted in altered consumer patterns, and consumption of alcoholic beverages is no exception. Beside the traditional alcoholic beverage soju, the consumers in the 1970s also began developing a taste for beer, which prior to that time had been virtually unaffordable. Oriental Brewery is one of the main beneficiaries of beer’s popularity. The company has recently succeeded in winning back significant market share, and it is now number one in the South Korean beer market. “The fine quality of our beer (along with an effective marketing strategy) was the prime contributor in our successful campaign to regain market leadership,” says Charles Park, Executive Director Oriental Brewery Company. “To maintain this level of product quality out into the future, we recently decided to make an additional investment in KHS filling technology and two KHS canning lines.”

Thiele Technologies introduces its new Salwasser Model ITL 300 Integrated Top Load Case Packer. The ITL 300 is a fully automatic case packer capable of top loading product into RSC or HSC cases. The sleek new design features a low, ergonomic knock down case magazine and a small overall footprint making the ITL 300 ideal for nearly any production line.