For the evaluation of the intrinsic lautering performance of malt an in-house test, predictive for both lauter tun and mash filter operations, has been used. Commercial thermostable endoxylanases added during mashing differ in their ability to increase the filtration rate. Especially the addition of a family 10 endoxylanase at mashing-in can be very efficient in view of wort filtration. Family 10 endoxylanases degrade barley arabinoxylans in an effective way and are not inhibited by the Hordeum vulgare L. xylanase inhibitor (HVXI) purified from barley. Moreover, the addition of this family 10 endoxylanase during germination has a positive effect on the filtration capacity of the kilned malt because the added endoxylanase activity is only partly destroyed during kilning..

Flavour is the significant criterion of evaluation in beer tasting, which depends on many primary and secondary causes. This includes desirable and un-desirable aromatic compounds, but also haptic and physical issues like viscosity, the CO2-level and colour. A beverage for example with a nontypical colour presented in a wrong drinking vessel is always evaluated differently to the “correct” form without any modifications.

Looking to the links and communication in the supply chain, he commented that procurement strategies which place opposing demands on commercial and technical departments are not sustainable. In particular, he identified that the growers, merchants, maltsters and end users who worked closely together were realizing benefits of sustainability that allowed better business management across the cycle. Volatility in prices on the open market resulted from short-term opportunism at various points in the chain. At the extreme, loss of malting barley to export markets, often as feed barley, could results in shortfalls for UK supply – which benefits no-one in the UK market for malt.

The precise determination of Bisphenol A (BPA) amounts in complex matrix like beer is presented. A practical, rapid and reliable sample preparation procedure for BPA determination is shown. The application of stable isotope dilution assay (SIDA) utilizing labmade deuterated BPA standards made it possible to obtain accurate analytical data. BPA concentrations in seven randomly chosen canned beers ranged from 1 µg BPA/L to 6.5 µg BPA/L. Compared to other canned foodstuff these amounts are low and presumably safe.

BrewingScience - Monatsschrift für Brauwissenschaft, 63 (September/October 2010), pp. 122-127

In the beverage industry labels are removed from returnable bottles in bottle cleaning machines. For a successful cleaning process the labels come-off time is crucial. If the labels detach too late in this process, they can block rinsing nozzles and affect the cleaning effectiveness of the machine.

The Hopsteiner Guidelines 2010 will soon be published and be available at BRAU 2010 in Nuremberg. We are still working on some details of the beer production and will present the balance of World Alpha Acid Supply and Demand as soon as possible.

The production of biogas from organic wastes originating during beer production offers an economically viable and environmentally sustainable alternative to existing recycling solutions. Using the biogas technology “ENBAFERM” patented by the Austrian company enbasys®, it is possible to integrate biogas production into an existing brewery, thus guaranteeing optimized energy production on-site. Since 2009, a demonstration system incorporating this technology has been in operation at the Bavarian State Brewery Weihenstephan in Freising, Germany. This system has been successfully used to ferment spent yeast and spent grain waste.

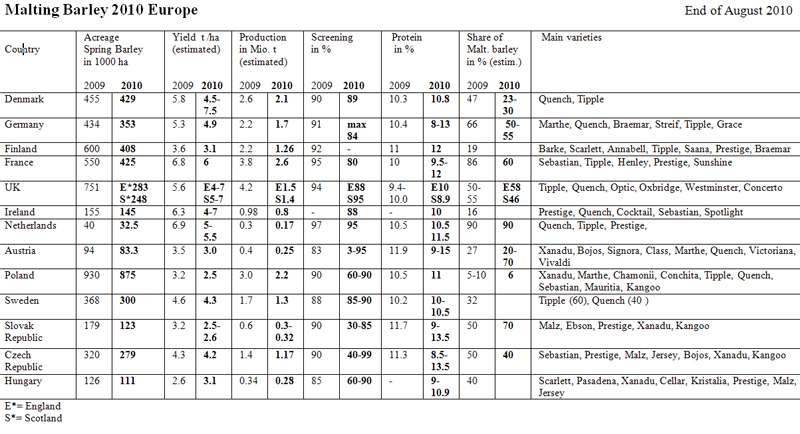

The weather conditions this year had a substantial effect on the spring barley throughout Europe. The harvest is going to be smaller than it was expected. There are going to be problems with the crops that were harvested late. One will probably expect a shortage with malting barley in Europe next year at the latest.

Light Stable Kettle Extract (LSKE) can be used to brew beers in much the same way as beers produced using conventional CO2-Extract.

Beer flavour is a very complex flavour created by interaction off several hundred aroma compounds. Obvious off-flavours which can be detected by the consumer decrease the drinkability and acceptance of a beverage. The image of a brand can be damaged. It is known that undesired flavours, like stale flavour, can be masked by positive ones like certain hop flavours. Therefore it is of interest to find out if other off-flavours can also be masked by positive aroma compounds. Positive flavour impressions are e.g. linalool and some esters among others. Whether these compounds can suppress the perception of

Isohumulones, an isomerisation product from hop (humulus lupulus sp.) derived humulones are the main bittering substance in beer. They contribute to more than 85 % of the allover bitterness of beer [65]. Hops and its constituents as well as its application in the brewery is subject of investigations for more than a century already. Hops as an ingredient in beer has been used since the early Middle Ages. The objective back than was to save beer from microbiological spoilage and to use the hops as a flavouring ingredient [6]. Today we know that hops and its constituents also improve foam stability and contributes to the flavour stability of beer in various ways [71]. This paper gives a short overview about the most important literature which was published throughout the last decades.

BrewingScience - Monatsschrift für Brauwissenschaft, 63 (July/August 2010), pp. 105-111